Embossing roller device, method of manufacturing topsheet using same, and absorbent article using same

A manufacturing method and technology of embossing rollers, which are applied to corrugated products, absorbent pads, chemical instruments and methods, etc., can solve the problems of uneven fiber density, difference in fiber density, small fiber density, etc., and achieve uniformity. , the contact area is minimized, the effect of improving the shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

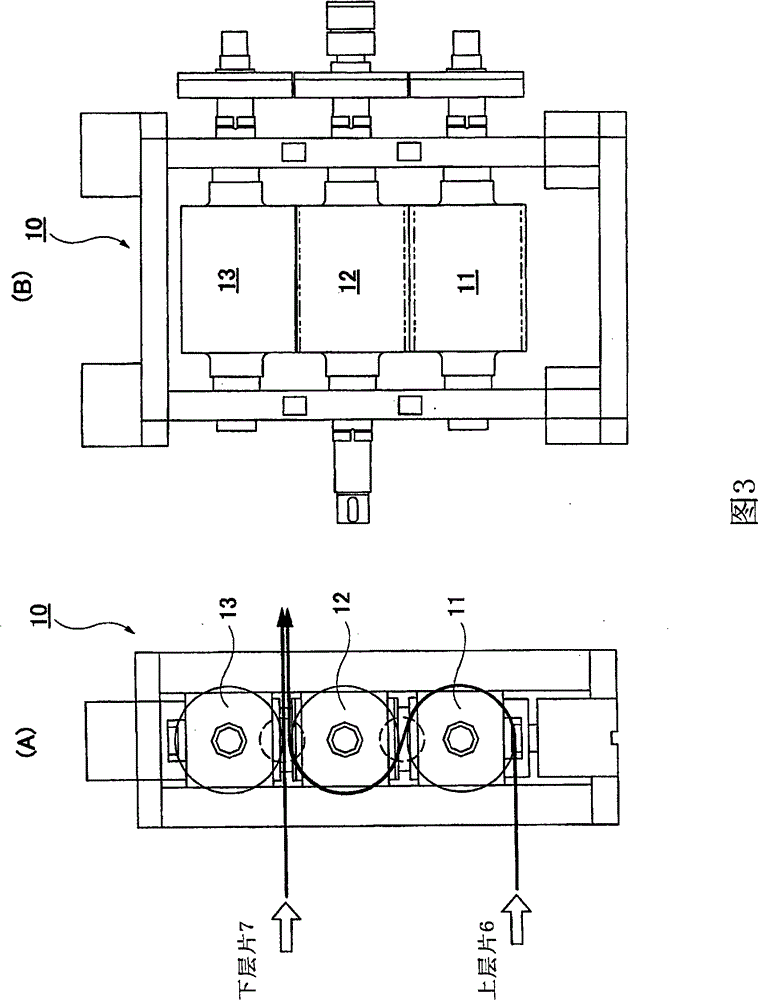

[0060] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0061] (Structure example of absorbent article 1)

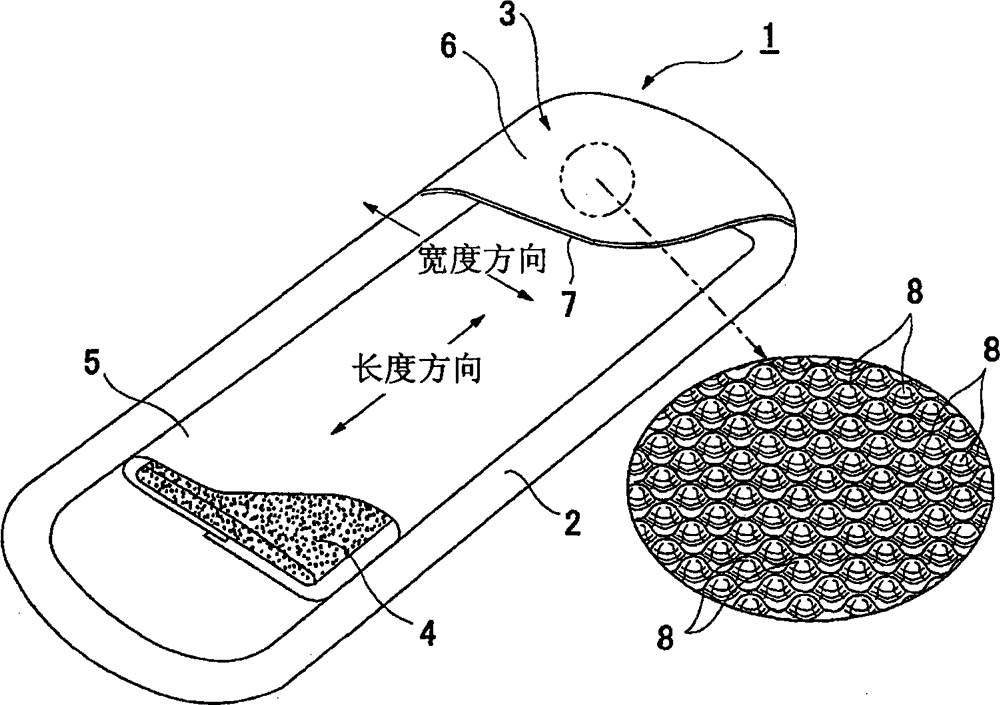

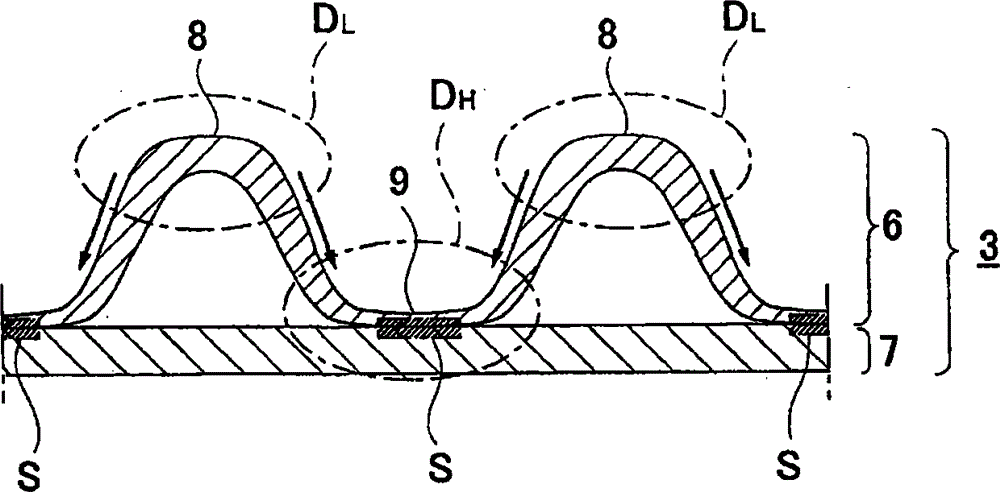

[0062] figure 1 The shown sanitary napkin 1 is mainly used for sanitary pads, sanitary napkins, leucorrhea sheets, incontinence pads, etc., and is structured as a liquid-impermeable back sheet 2 and a liquid-permeable surface sheet 3 (hereinafter referred to as The absorber 4 or the absorber 4 surrounded by the crepe paper 5 as shown in this figure is interposed between (referred to as a surface sheet). Around the absorber 4, the liquid-impermeable backsheet 2 and the topsheet 3 are bonded together by means of hot-melt adhesive or the like.

[0063] The above-mentioned liquid-impermeable reverse sheet 2 uses a sheet material having at least water-repellent properties such as polyethylene and polypropylene. In addition, it is also possible to use a non-woven fabric sheet ( In this case, a liquid-impermeable back she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com