Absorbency substance

An absorbent and article technology, used in absorbent pads, medical science, clothing, etc., can solve the problems of reduced cushioning, more contact area, and smaller bulge, so as to improve shape retention, improve skin feel, and eliminate stiffness. sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

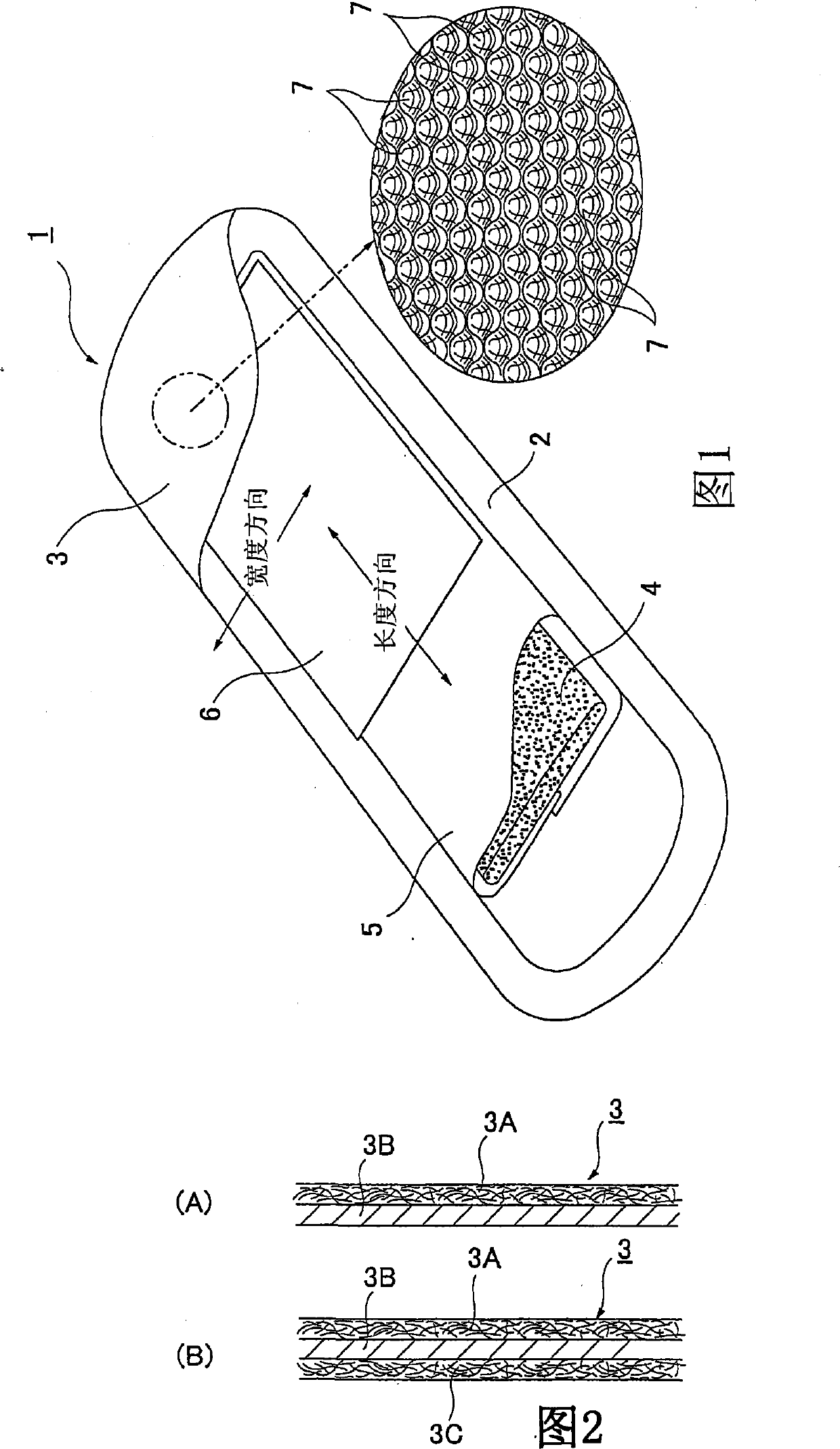

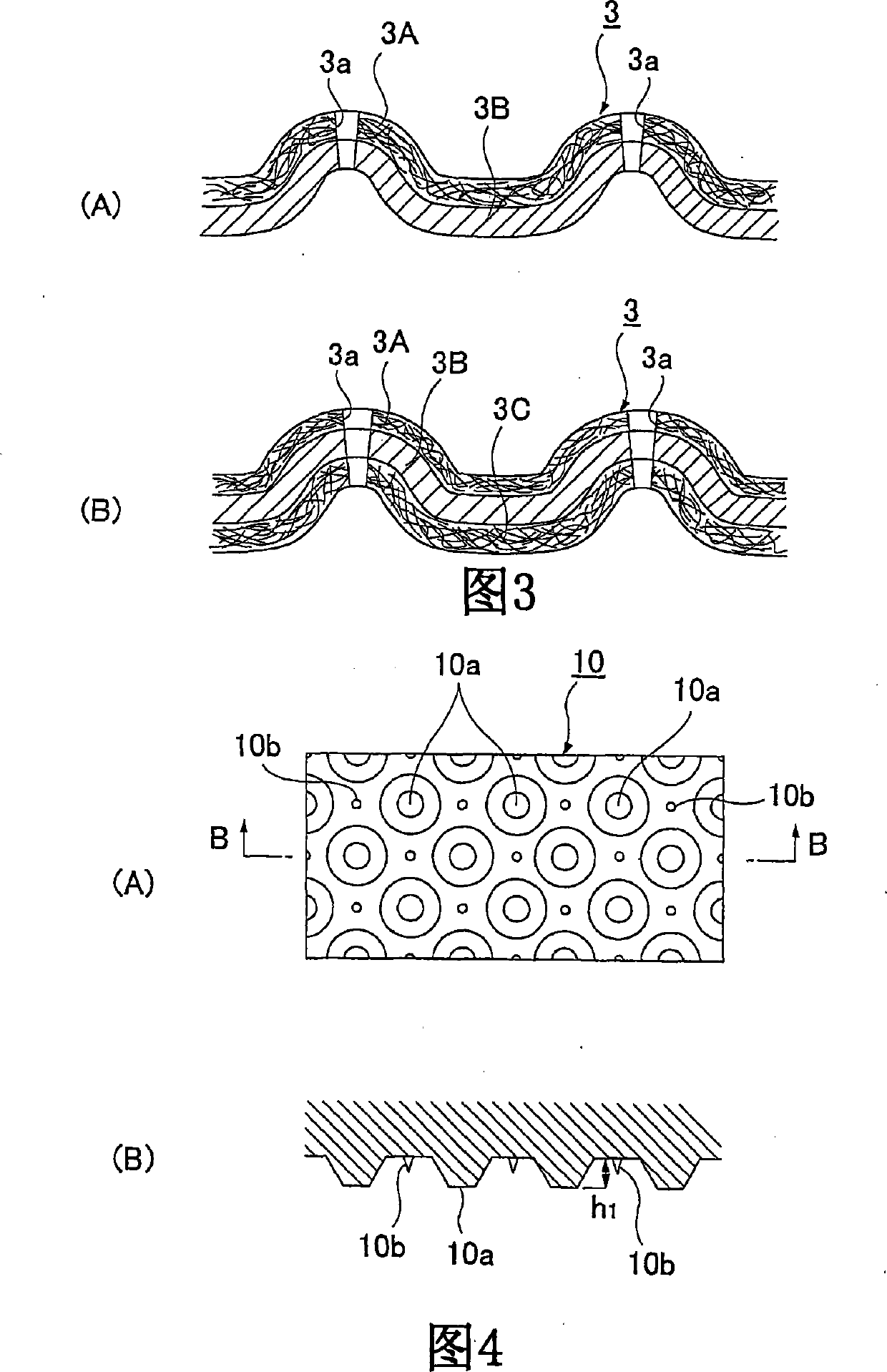

[0068] The above-mentioned front sheet 3 uses a liquid-permeable sheet formed as follows: at least a non-woven fabric layer constituting the skin-contacting surface layer and a plastic film layer laminated on the non-skin-contacting surface side of the non-woven fabric layer. The layer sheet is subjected to a concave-convex embossing process consisting of a plurality of protruding portions 7, 7..., and the convex embossing part or concave embossing part in the concave-convex embossing is implemented. hole treatment.

[0069] The base material of above-mentioned face sheet 3 constitutes, specifically as shown in Figure 2 (A), can use the thin sheet of double-layer structure that is made of hydrophobic non-woven fabric layer 3A / plastic film layer 3B, or by hydrophilic non-woven fabric layer. The sheet of the double-layer structure that woven fabric layer 3A / plastic film layer 3B constitutes, or as shown in Figure 2 (B), use is made of hydrophobic nonwoven fabric layer 3A / plastic...

no. 2 example

[0081] In the above-mentioned first embodiment, the opening 3a is applied to the convex embossing part in the above-mentioned concave-convex embossing, but in this second embodiment, as shown in FIG. The embossing applies openings 3a.

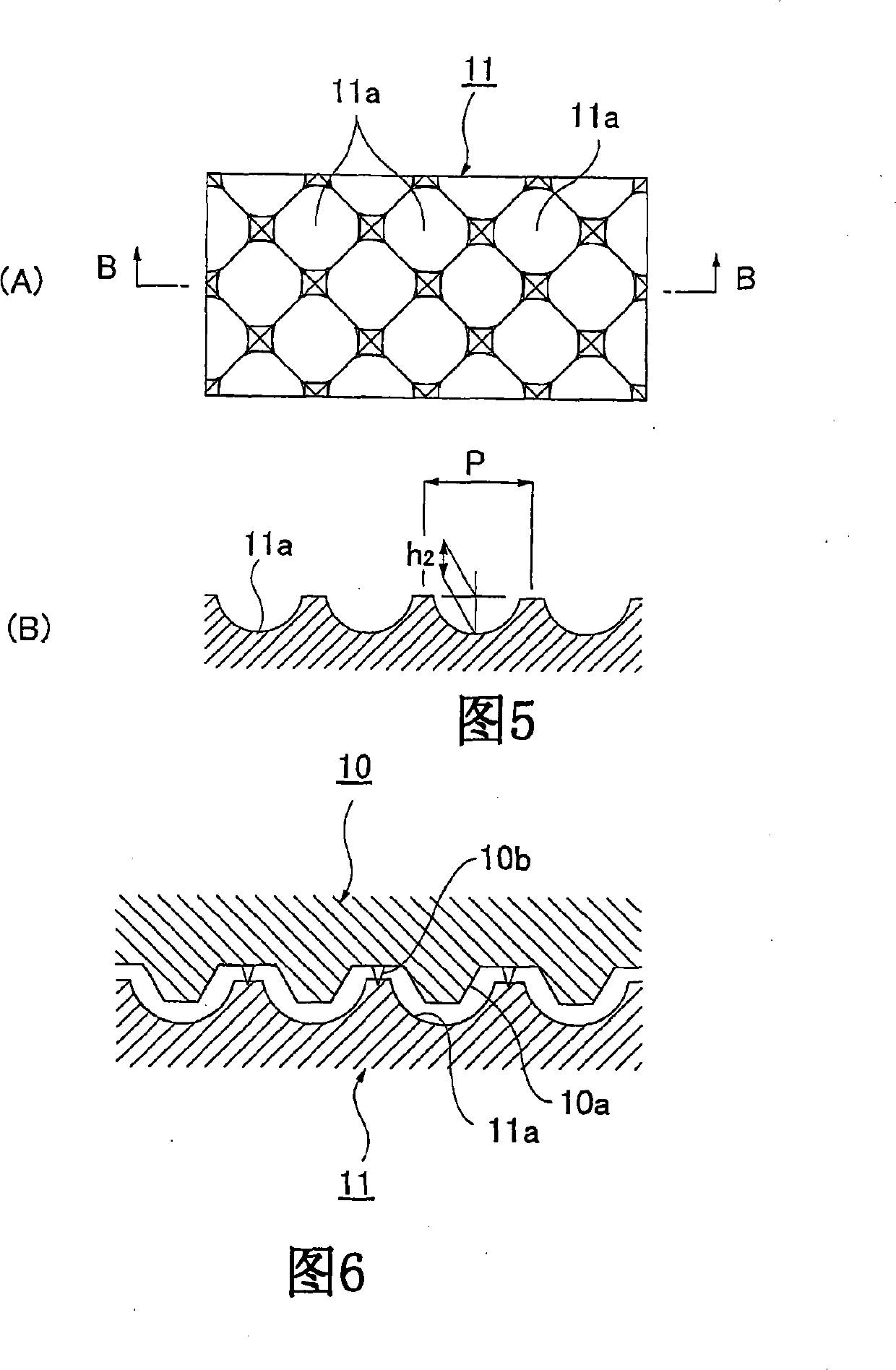

[0082] When embossing and perforating the above-mentioned front sheet 3, a convex side embossing roll 10 as shown in FIG. 8 and a concave side embossing roll 11 as shown in FIG. 9 are used. 10 is provided with a plurality of convex parts 10a, 10a..., and a pin embossing 10b is formed in the approximate center of each convex part 10a, 10a, and the concave side embossing roller 11 corresponds to the above-mentioned convex part 10a. A plurality of concave-shaped parts 11a, 11a... are formed, and the surface sheet 3 passes between these convex-side embossing rolls 10 and concave-side embossing rolls 11, so that The embossing is applied while giving the opening 3a to the concave embossed portion by the above-mentioned pin embossing 10b, 10b, . . . ...

no. 3 example

[0086] In the third embodiment, as shown in FIG. 11, on the reverse side of the above-mentioned front sheet 3, the above-mentioned second non-woven fabric composed of a material having a melting point lower than the above-mentioned non-woven fabric layer 3A is bonded by thermal fusion or thermal fusion bonding. In the state of the sheet 6, under the heating conditions above the melting point of the above-mentioned plastic film layer 3B and the second non-woven fabric sheet 6 and less than the melting point of the above-mentioned non-woven fabric layer 3A, as shown in FIG. Concavo-convex embossing processing composed of a plurality of protruding portions 7, 7..., and performing hole processing on the convex embossing part or concave embossing part in the concavo-convex embossing ( not shown).

[0087] The above-mentioned second nonwoven fabric sheet 6 only needs to be hydrophilic to body fluids. Specifically, materials that have been made hydrophilic by using regenerated fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com