Protective cover of printer

A technology for printers and protective covers, which is applied in the field of protective covers, and can solve problems such as the infringement of workers by harmful releases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

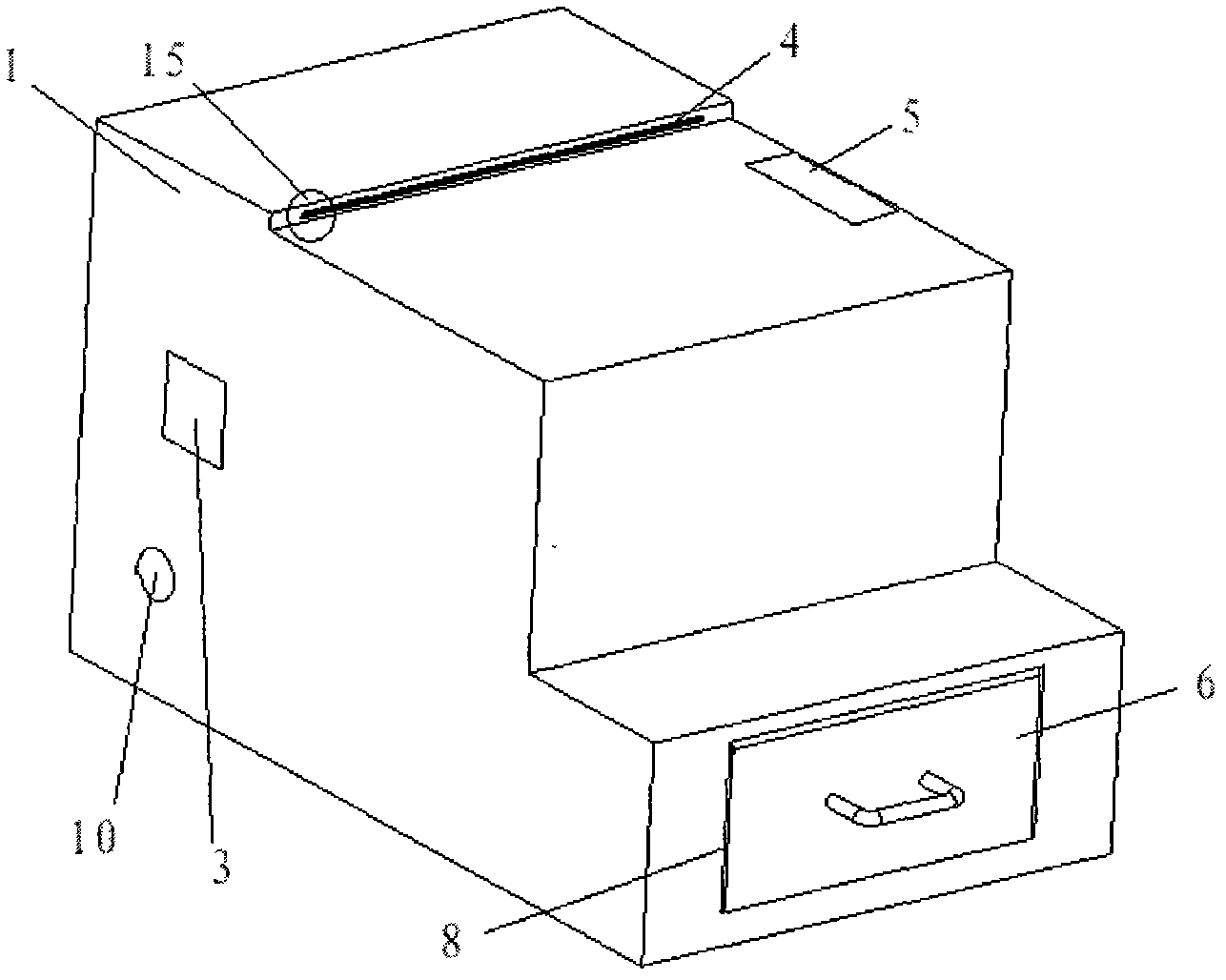

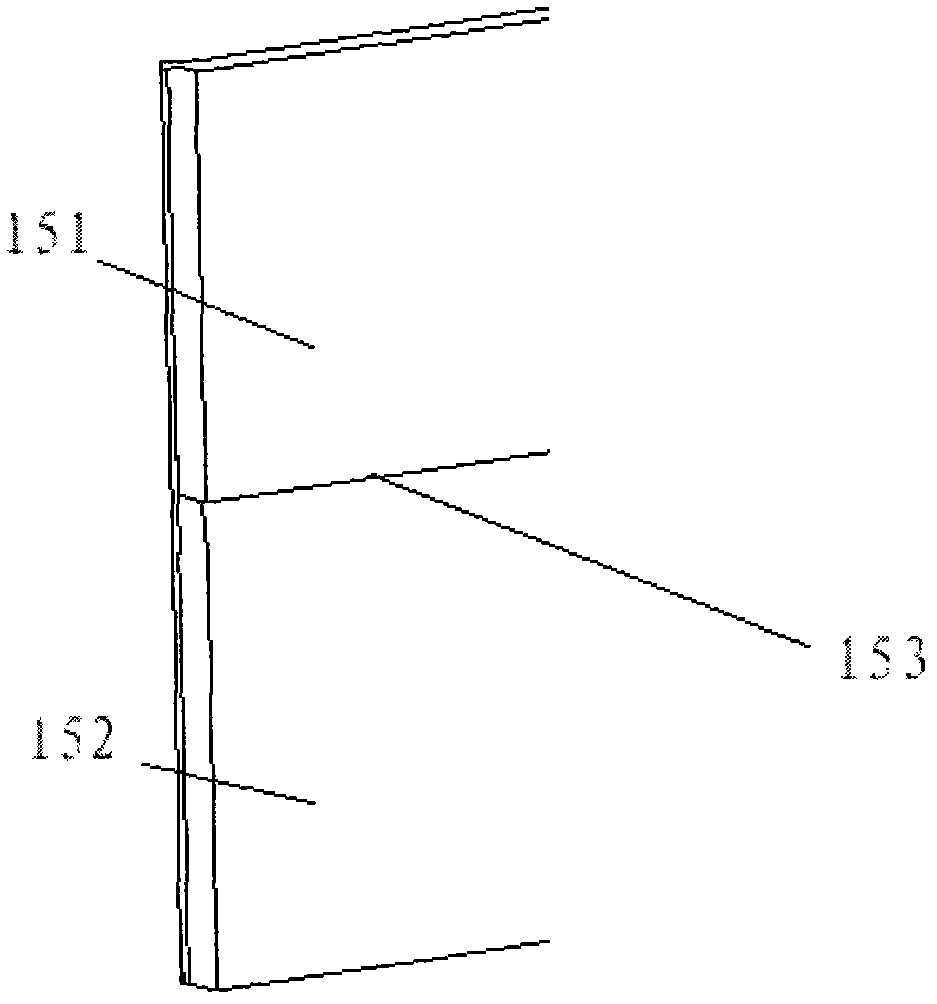

[0015] Such as figure 1 As shown, a paper outlet opening (4) is designed on the protective cover housing (1), and the size is equivalent to that of the printer outlet. During the use of the printer, the paper outlet opening can spit out the printed paper (13). The paper outlet opening (4) is connected with a paper outlet rubber sheet (15);

[0016] One side of the protective cover housing (1) has a display opening (5) slightly larger than the printer display screen and button area, and when the printer protective cover covers the printer, the printer display screen and related buttons can be exposed;

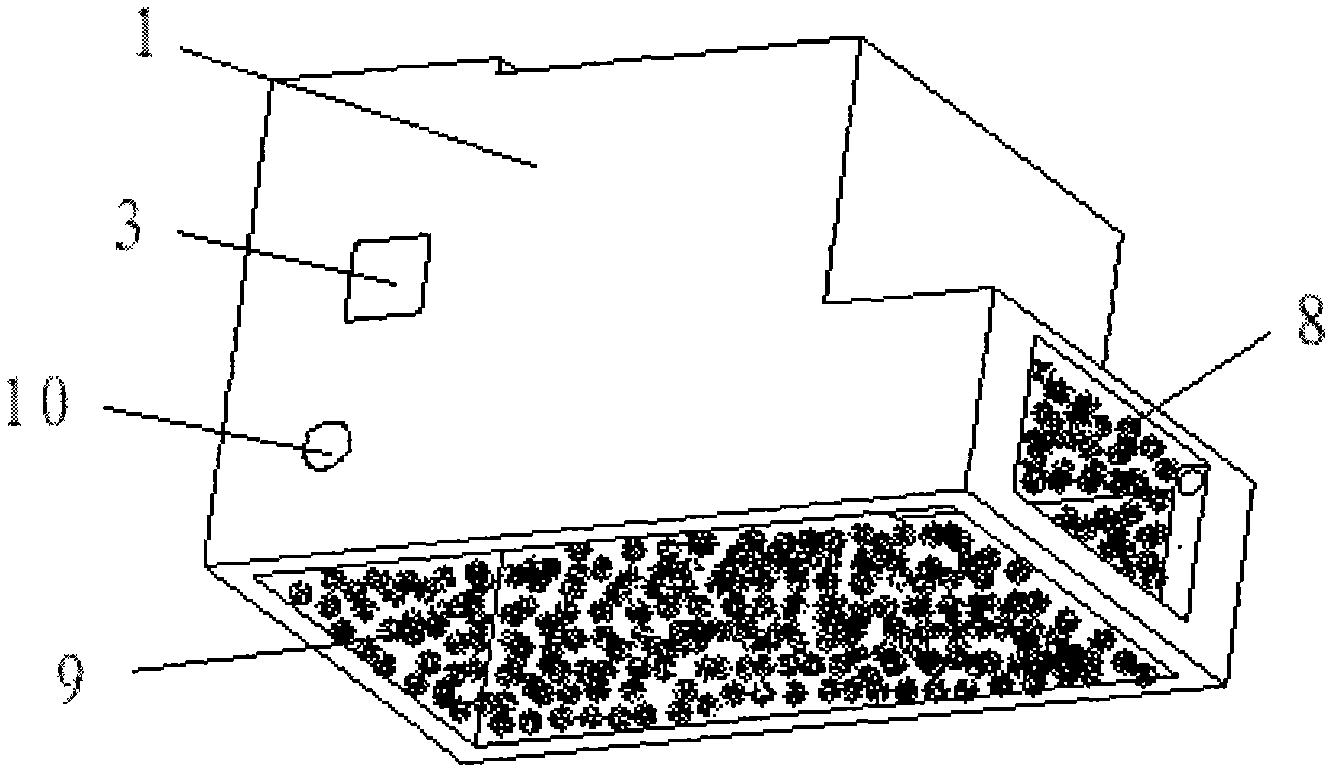

[0017] The protective cover housing (1) is provided with a cover plate (6) which can be opened freely. The cover plate (6) is slightly larger than the paper inlet (8) of the printer. On the protective cover shell (1);

[0018] A circuit opening (10) and a switch opening (3) are designed on the protective cover housing (1). The line opening (10) and the switch opening (3) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com