Heating system using self-operated three-way water-mixing temperature regulating valve

A technology of mixing water temperature and heating system, which is applied in heating system, multi-way valve, household heating, etc., to achieve the effect of simple equipment and avoiding imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

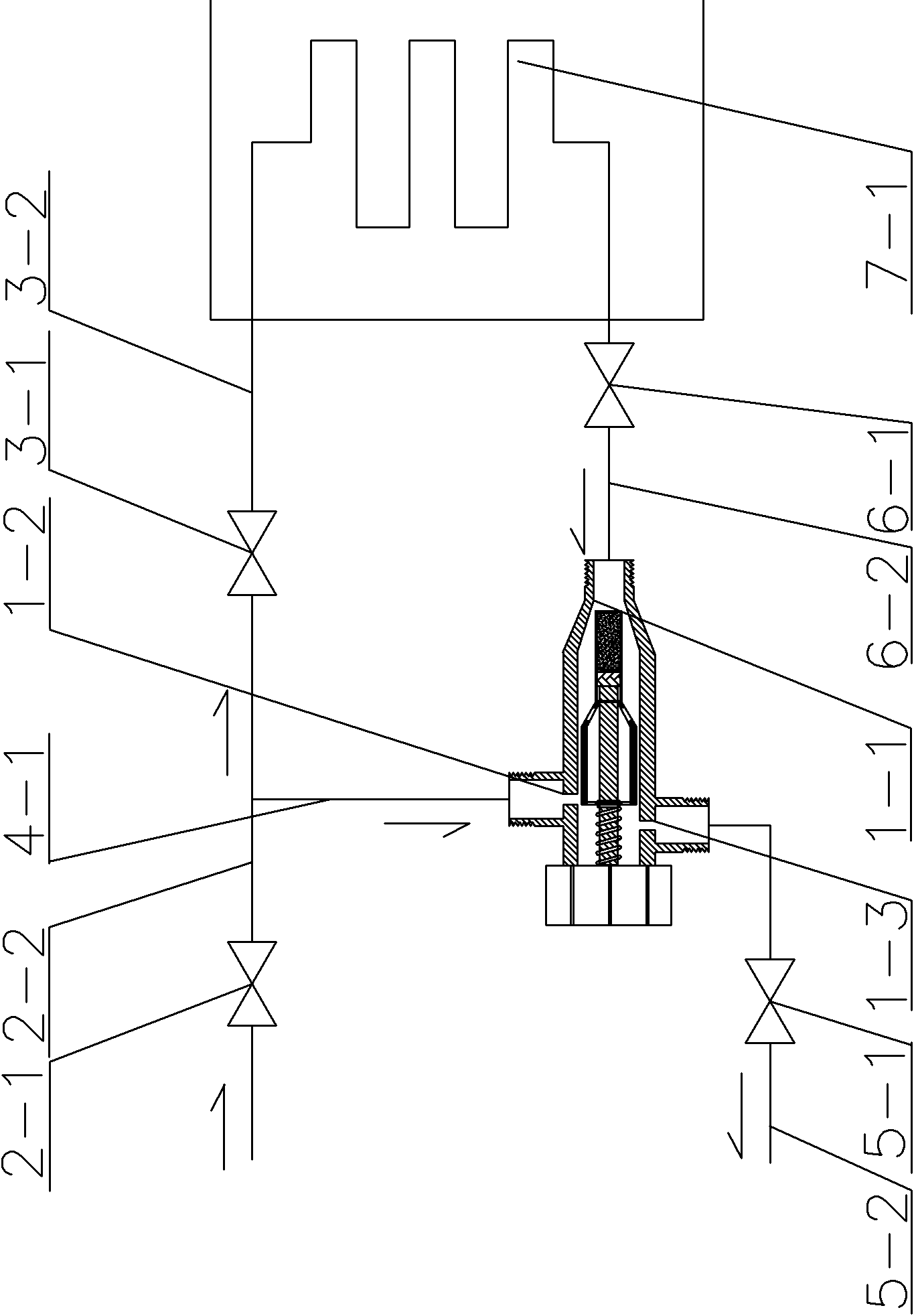

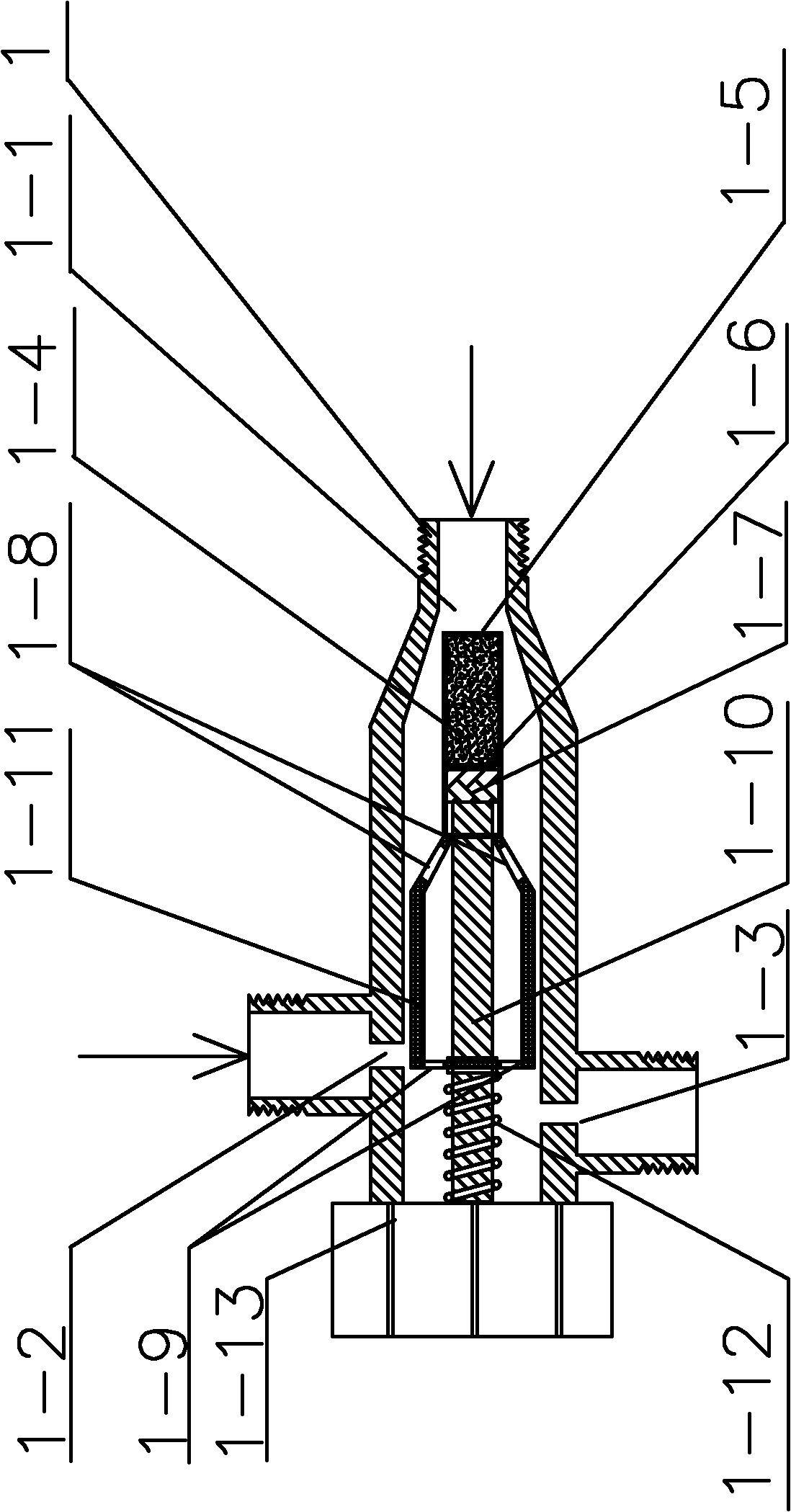

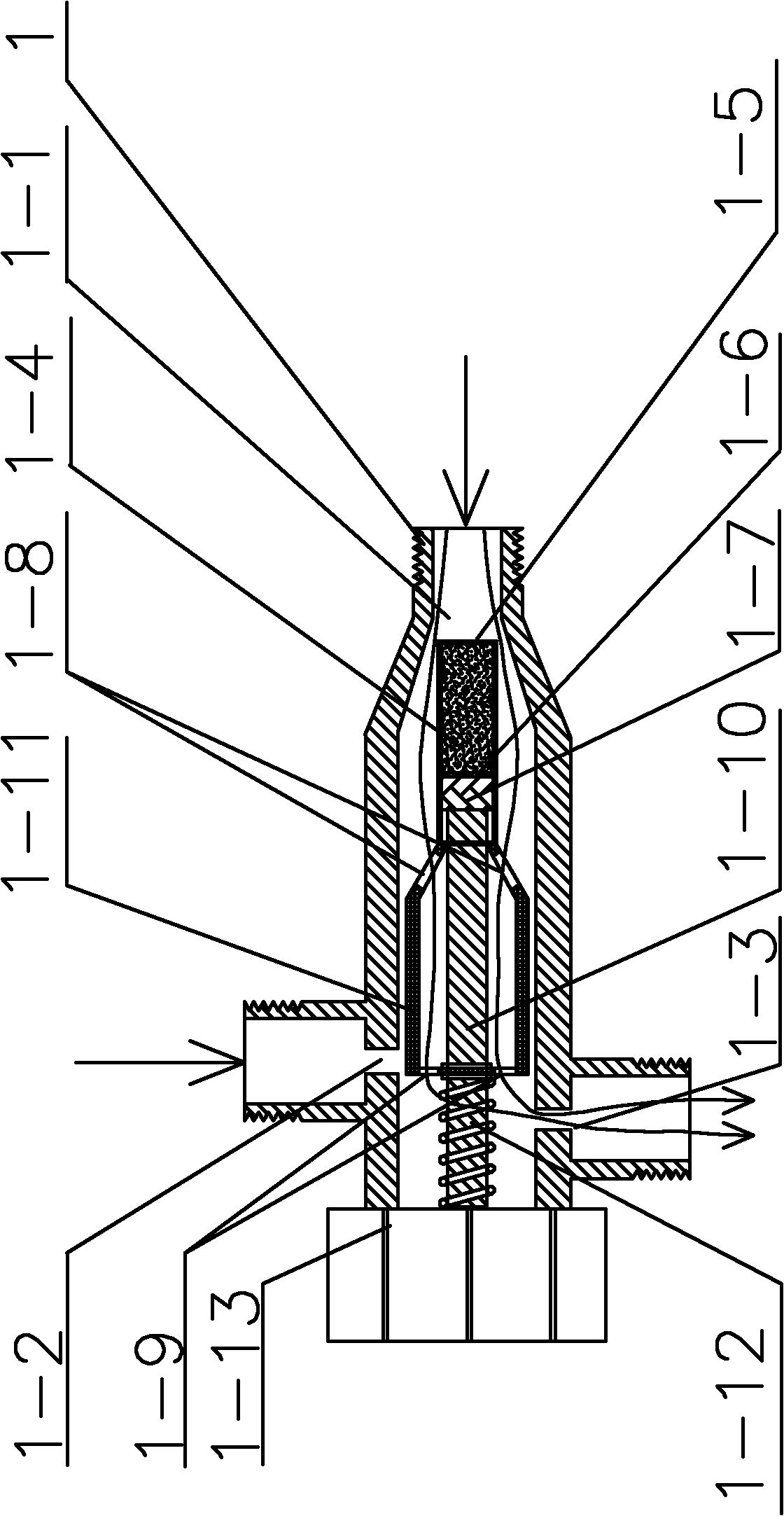

[0009] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the system of this embodiment includes external network water supply pipe 2-2, user water supply pipe 3-2, bypass water mixing pipe 4-1, external network return water pipe 5-2, user return water pipe 6-2 and multiple A series heating user 7-1, characterized in that the system also includes a temperature regulating valve, the temperature regulating valve is composed of a valve body 1, a paraffin temperature package 1-4, a metal shell 1-5, a diaphragm 1-6, a rubber Plug 1-7, valve core 1-8 with water inlet, valve core 1-9 with water outlet, nylon connecting rod 1-10, nylon valve core 1-11, spring 1-12 and temperature control handle 1-13 One end of the valve body 1 is a small-diameter end, the other end of the valve body 1 is a large-diameter end, the small-diameter end of the valve body 1 is the first inlet 1-1, and the side wall of the upper end of the valve body 1 is provided wit...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the system of this embodiment also includes an external network water supply regulating valve 2-1, and the external network water supply pipe 2-2 is provided with an external network water supply regulating valve 2-1, and this structure is used to adjust the external network water supply. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the system of this embodiment also includes a user water supply regulating valve 3-1, and the user water supply pipe 3-2 is provided with a user water supply regulating valve 3-1, and this structure is used to regulate the user water supply. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com