Optical member, lighting device, display device, television receiver and manufacturing method of optical member

A technology of optical components and manufacturing methods, applied in optical elements, optics, nonlinear optics, etc., can solve the problems of outgoing light diffusion and low light utilization efficiency, and achieve the effect of suppressing moiré

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

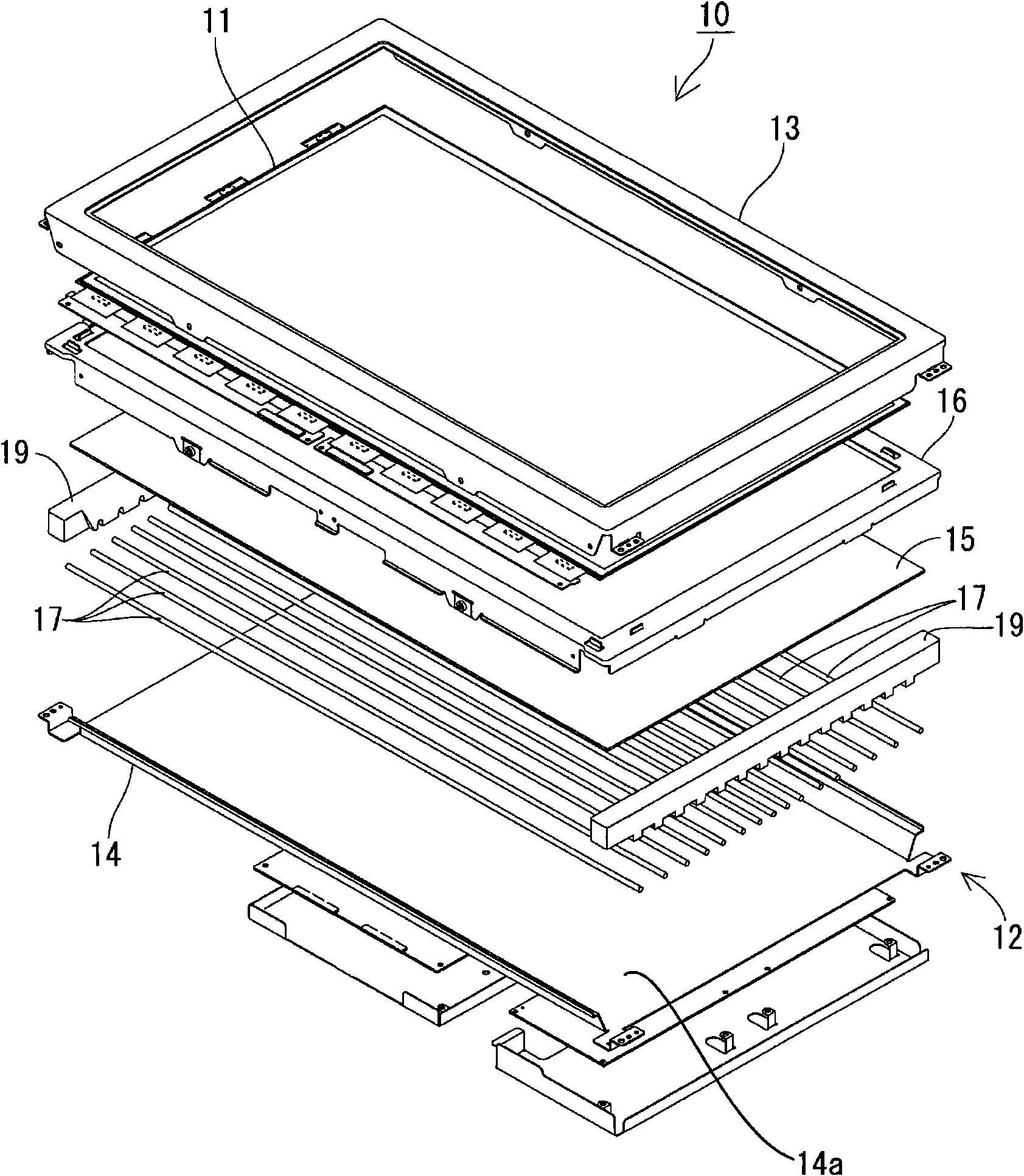

[0063] pass Figure 1 to Figure 20 Embodiment 1 of the present invention will be described.

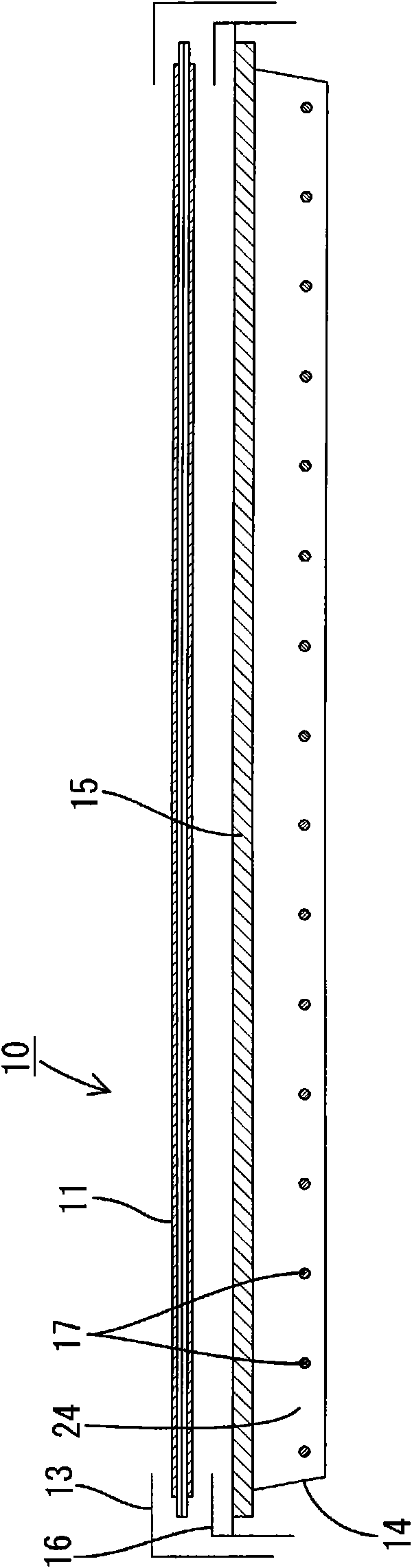

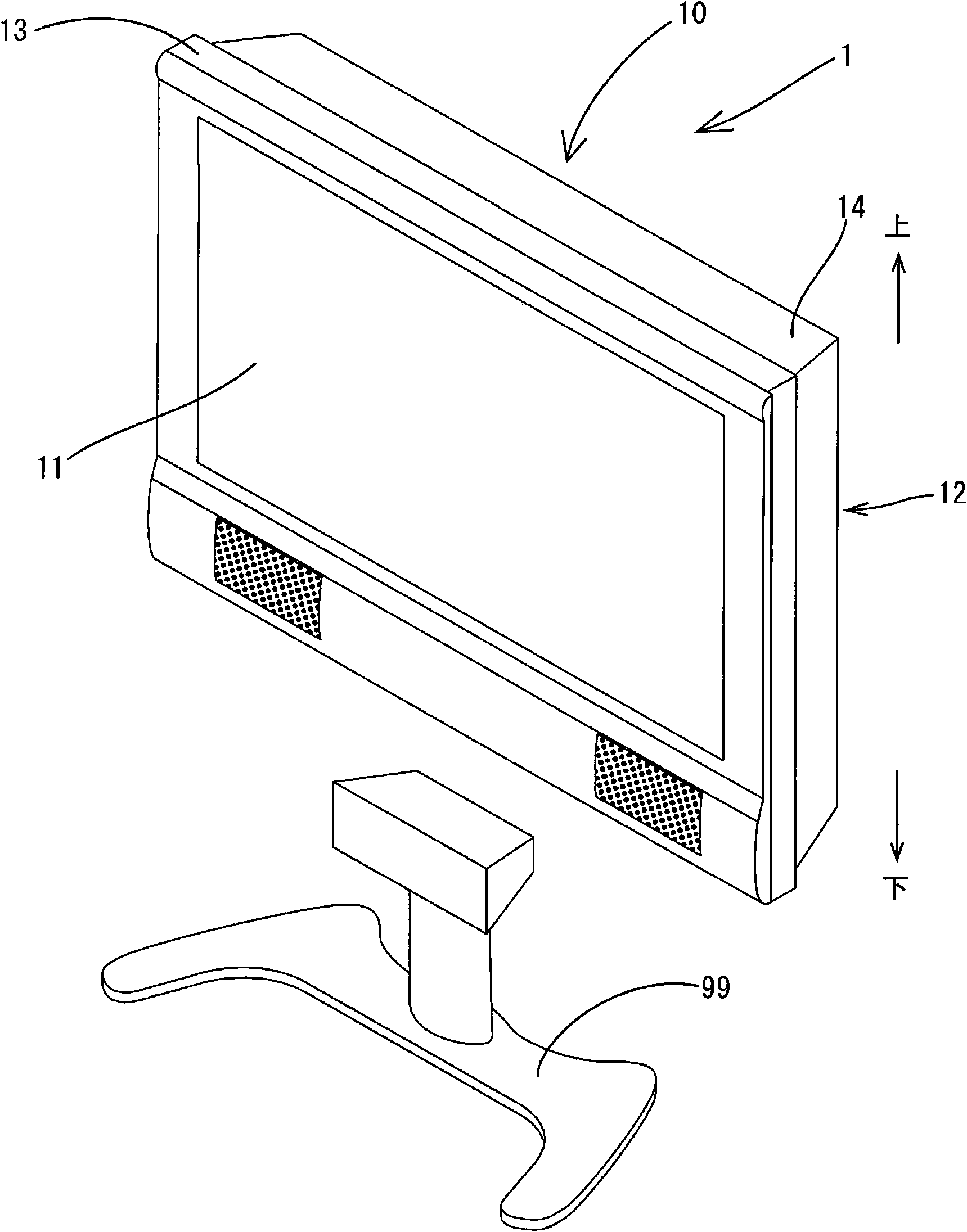

[0064] The liquid crystal display device 10 of this embodiment is as figure 1 with figure 2 As shown, a rectangular liquid crystal panel (display panel) 11 in plan view and a backlight device (illumination device) 12 as an external light source are provided, and they are integrally held by a case 13 or the like. The liquid crystal display device 10 is, for example, image 3 As shown, it can be applied to a television receiving device 1, which is composed of a liquid crystal display device 10 and a base 99 supporting the liquid crystal display device 10 from below. The liquid crystal panel 11 and the backlight device 12.

[0065] The liquid crystal panel 11 has a well-known structure in which a liquid crystal (liquid crystal layer) whose optical properties change according to an applied voltage is sealed in a gap between a transparent TFT substrate and a transparent CF substrate....

Embodiment approach 2

[0118] pass Figure 21 or Figure 22 Embodiment 2 of the present invention will be described. In Embodiment 2, it is shown that the microlenses 23 employ two types of sizes, large and small. In addition, in this second embodiment, redundant descriptions of the same structures, operations, and effects as those of the above-mentioned first embodiment will be omitted.

[0119] The microlenses 23 formed in the optical member 15 of the present embodiment have two types of planar view sizes, including large microlenses 23A and small microlenses 23B. In the present embodiment, moiré is suppressed by setting the difference between the planar size of the large microlens 23A and the small microlens 23B and the planar size of the pixel PE of the liquid crystal panel 11 to be equal or greater.

[0120] The specific setting of the plan view size of the large and small microlenses 23 will be described in detail. When the plan view size of the large microlens 23A is Lm1 and the plan view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com