Device for arranging and debugging linear laser light source and method thereof

A linear laser, installation and debugging technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem of affecting the positioning accuracy, inaccurate installation of linear laser light sources, and difficulty in judging a word Whether the optical axis of the linear laser light source is parallel to the touch panel, etc., to achieve an accurate and convenient debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

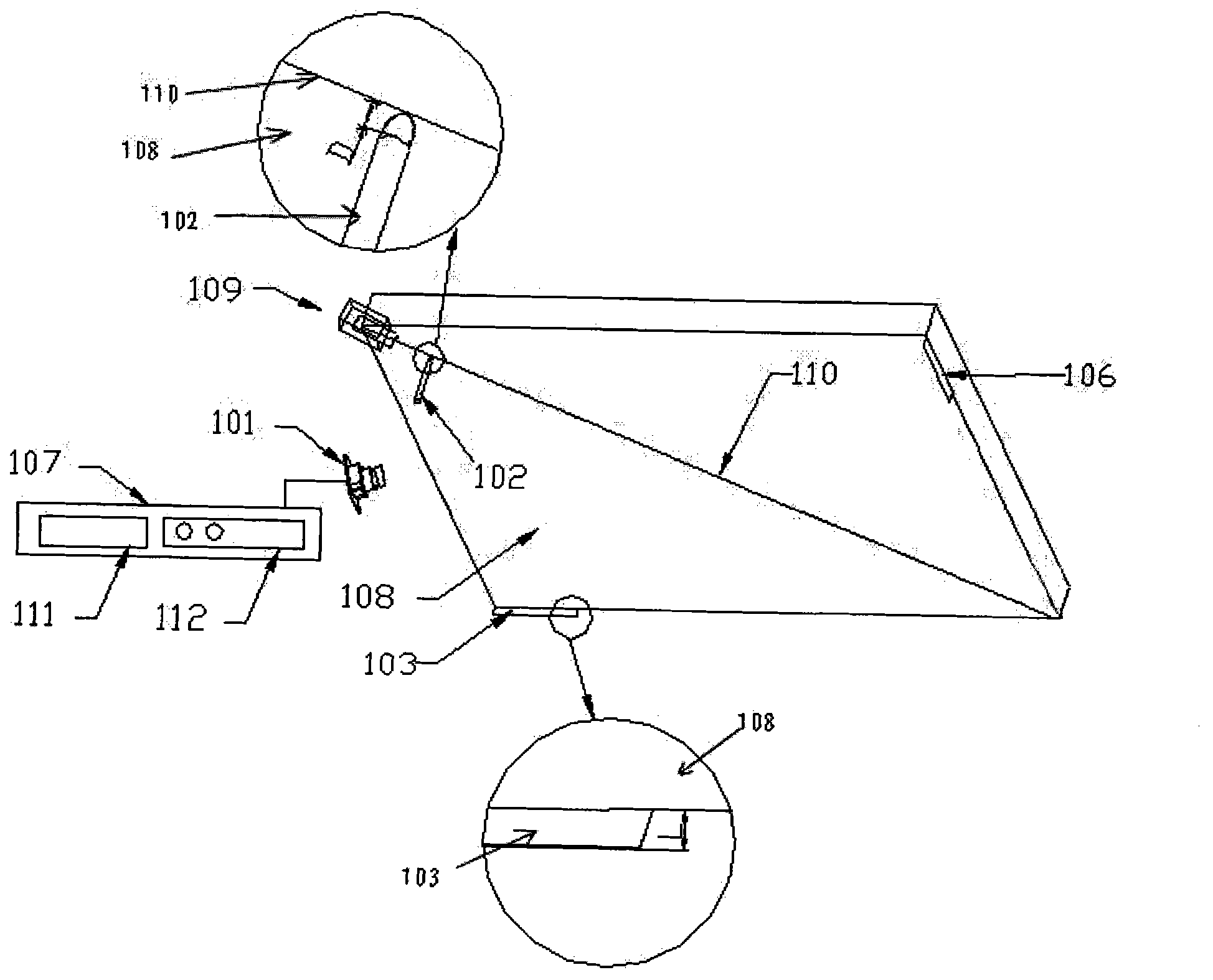

[0042] see figure 1 As shown, the linear laser light source is placed on the corner of the touch panel. In the case of needing multiple inline laser light sources, since each inline laser light source is in this situation, the device and method for installation and debugging are similar, this embodiment only illustrates the specific implementation steps of one inline laser light source .

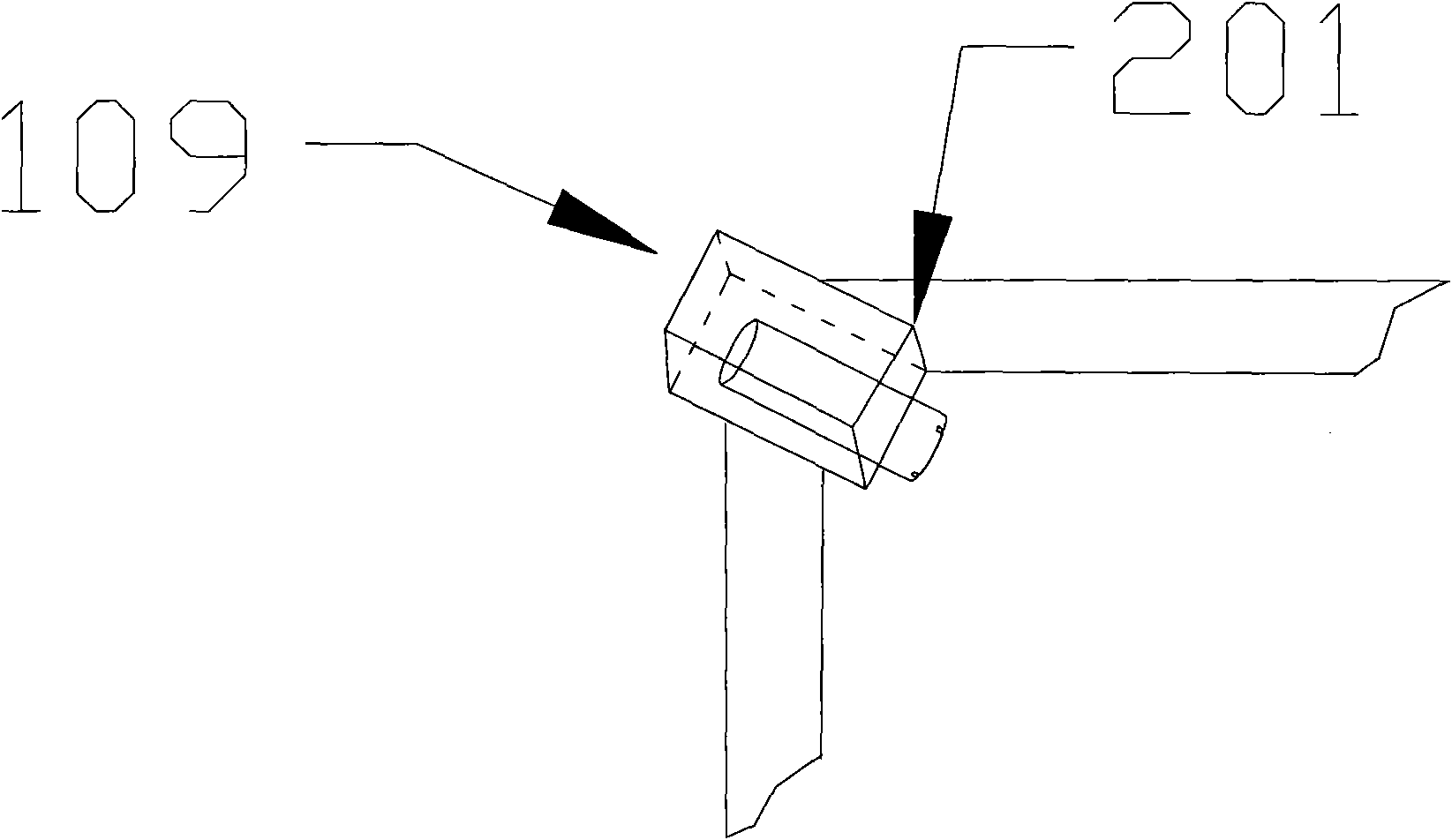

[0043] The device for installing and debugging an inline laser light source of the present invention is composed of a camera 101 , a passive pen 102 , reflective strips 103 and 106 , and a debugging instruction module 107 .

[0044] Wherein, the reflective strips 103, 106 are respectively placed on the two intersection positions of the two illumination boundary lines of the inline laser light source required by the touch panel and the frame of the touch panel; in this embodiment, the reflective strips It is white paper with a height L of 5mm.

[0045]The camera 101 is placed at a positio...

Embodiment 2

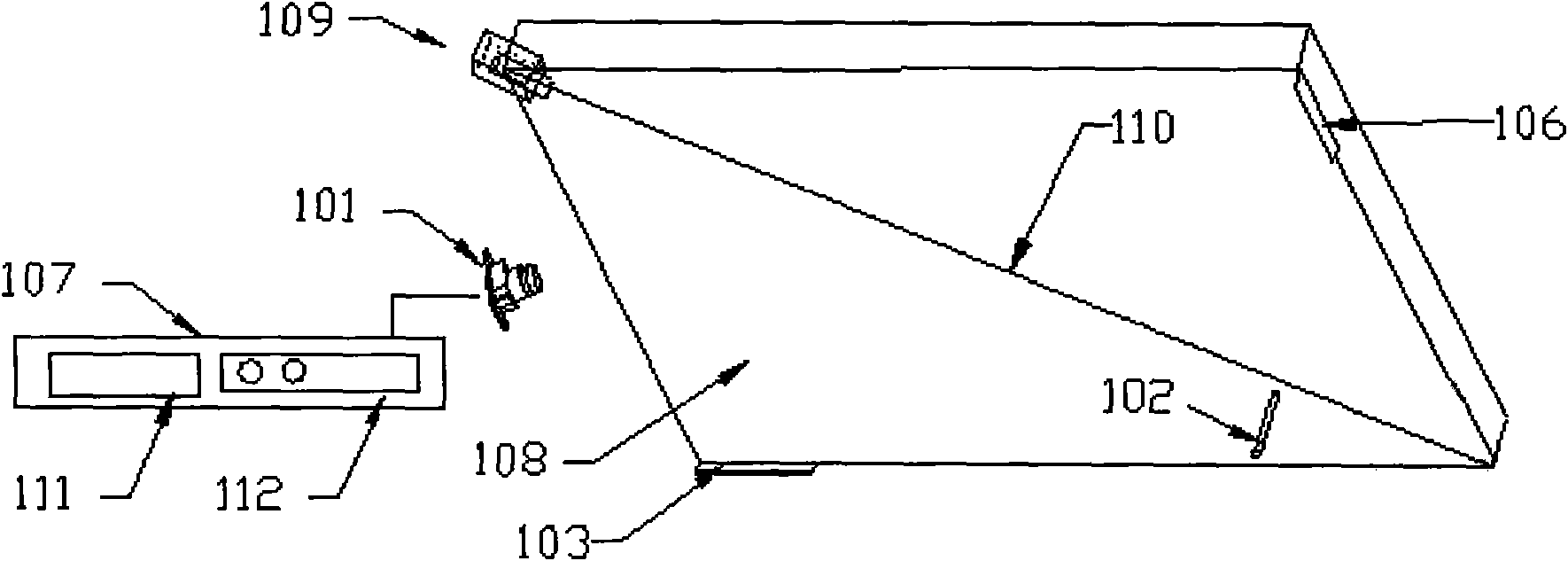

[0066] see Image 6 As shown, the difference between this embodiment and the previous embodiment is that the linear laser light source is placed on the edge of the touch panel, while the previous embodiment is placed on the corner of the touch panel. Since the installation and debugging devices and methods of each inline laser light source are similar in this situation, this embodiment only illustrates the specific implementation steps of one inline laser light source.

[0067] A device for installing and debugging an inline laser light source of the present invention is composed of a camera 101 , a passive pen 102 , reflective strips 103 and 104 , and a debugging indicator module 107 .

[0068] Wherein, the reflective strips 103, 104 are placed on the two intersection positions of the two illumination boundary lines of the linear laser light source required by the touch panel and the two intersection positions of the touch panel frame; the reflective strips are white paper or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com