Graphical Structure and Method of Insulation Reliability Test of PCB Finished Products

A graphic structure, PCB board technology, used in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problem of not being able to test the insulation performance parameters of PCB boards in batches, accurately and comprehensively, to avoid PCB micro The effect of short-circuit-like phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

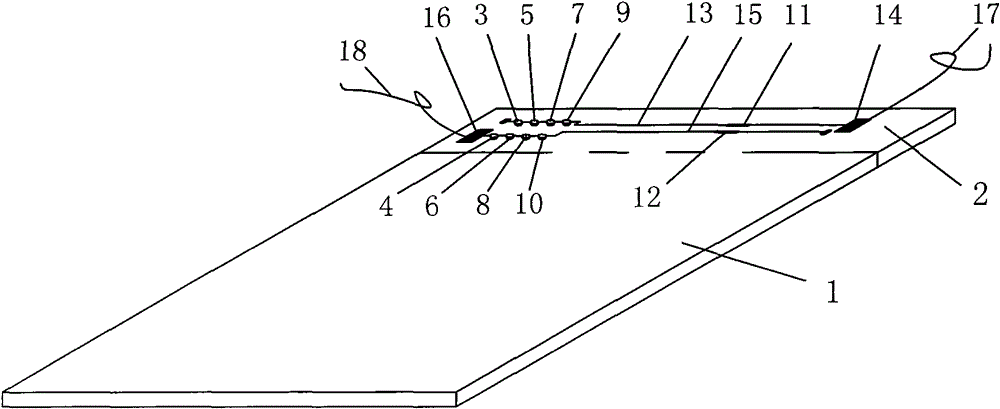

[0017] Such as figure 1 Shown is the graphic structure diagram of the reliability test of the preferred embodiment of the present invention, the graphic structure of the finished product insulation reliability test of the PCB board, which includes a PCB board 1, a process edge located on one side of the PCB board 2. The process side 2 is provided with multiple rows of via holes and pads, each row of via holes and pads are connected to form a network through a wire, and a network pad is provided at one end of the network wire. In this embodiment, the thickness of the PCB board 1 is 1.6mm, and the length and width are 100mm×200mm. The process edge is set on the upper end of the PCB board, generally larger than 5mm. The via holes are four pairs of eight holes 3, 4, 5, 6, 7, 8, 9, 10, arranged in two rows up and down. The pads 11, 12 are a pair arranged up and down. The first row of via holes 3 , 5 , 7 , 9 and the first pad 11 are connected to form a first network through a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com