Portable self-adjustment wheel type probe bracket for rail flaw detecting car

A rail flaw detection car, automatic adjustment technology, applied to railway car body parts, railway vehicle shape measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve rail head crushing, rail bottom corrosion, and crescent blocks, etc. problems, to achieve the effect of convenient adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

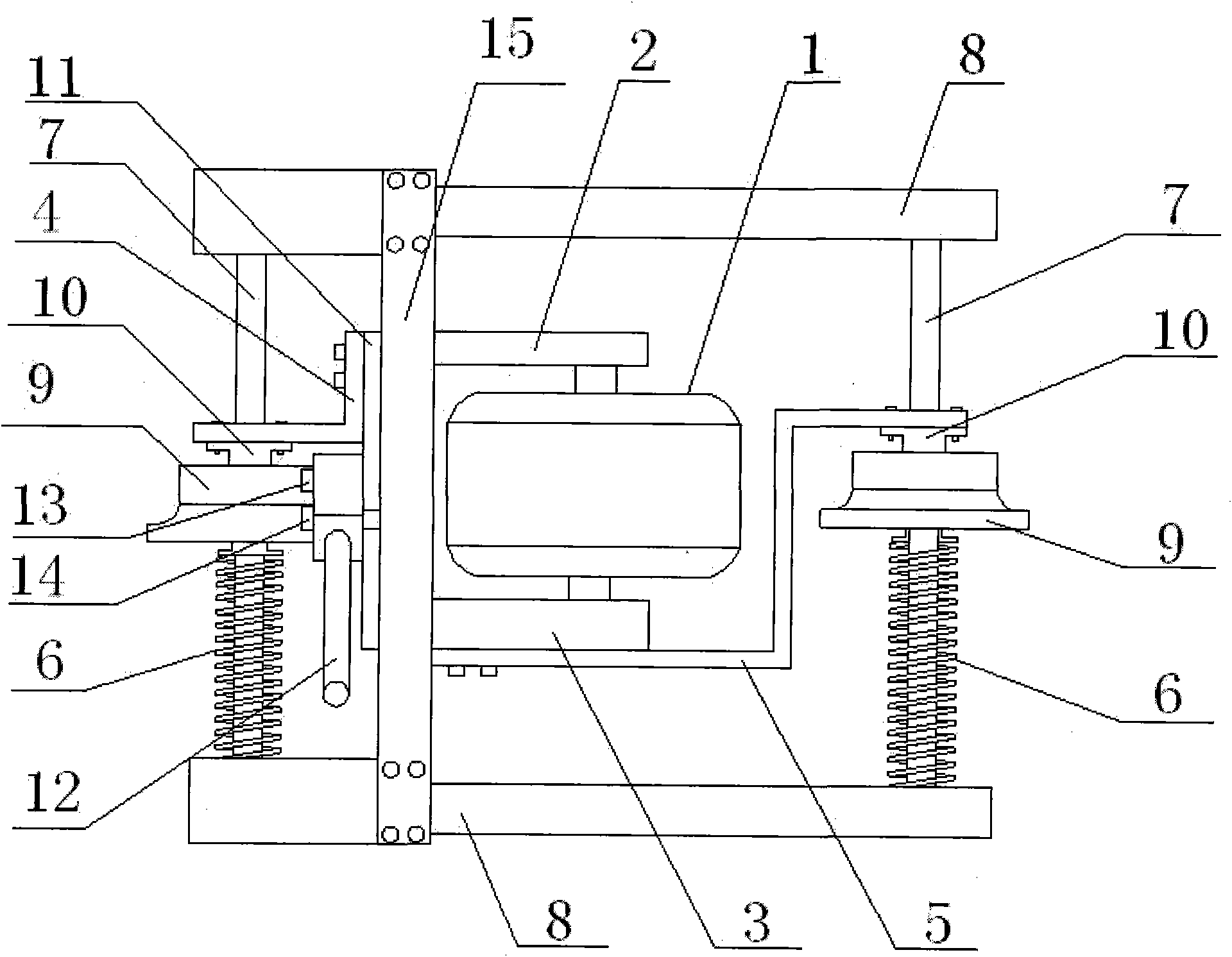

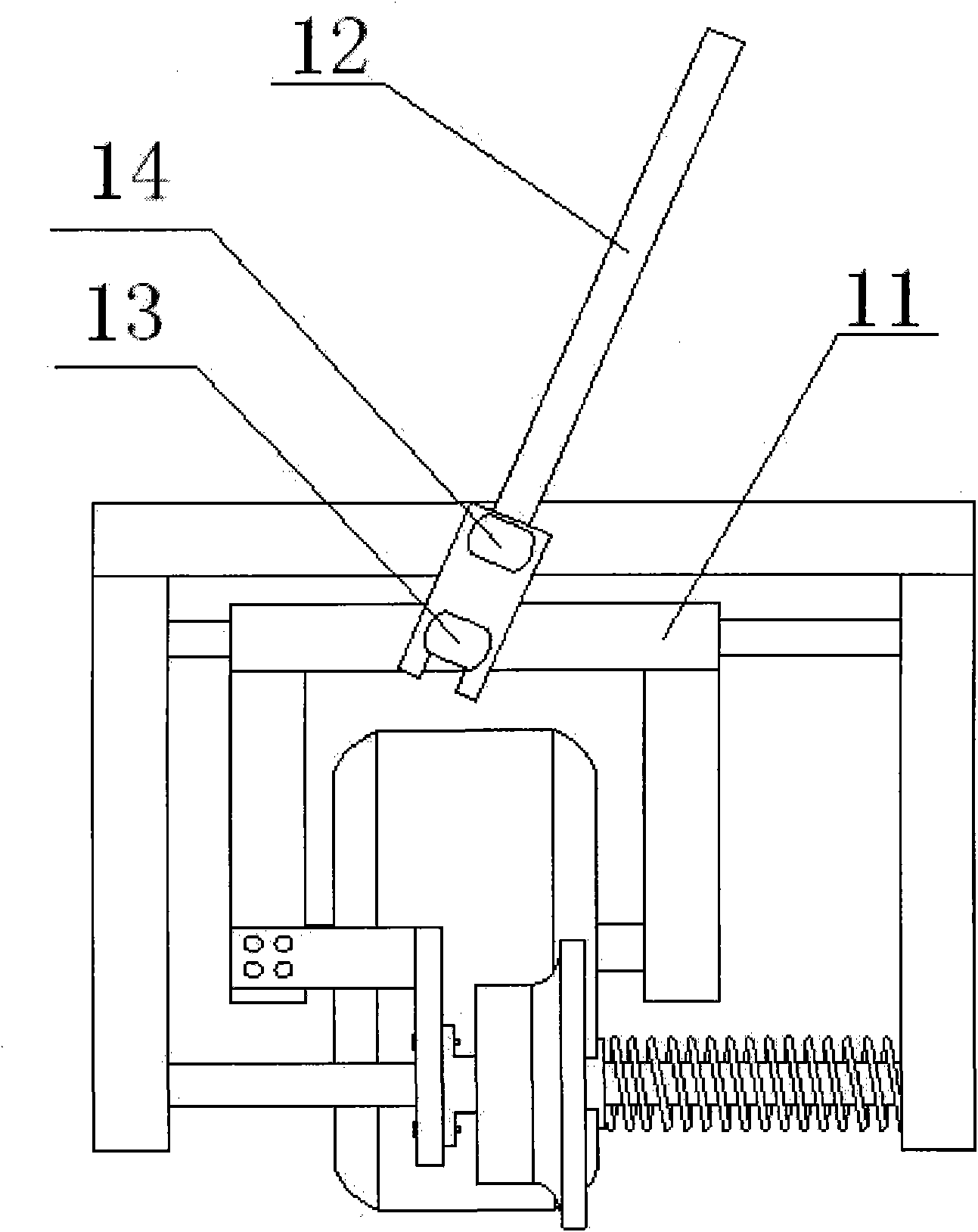

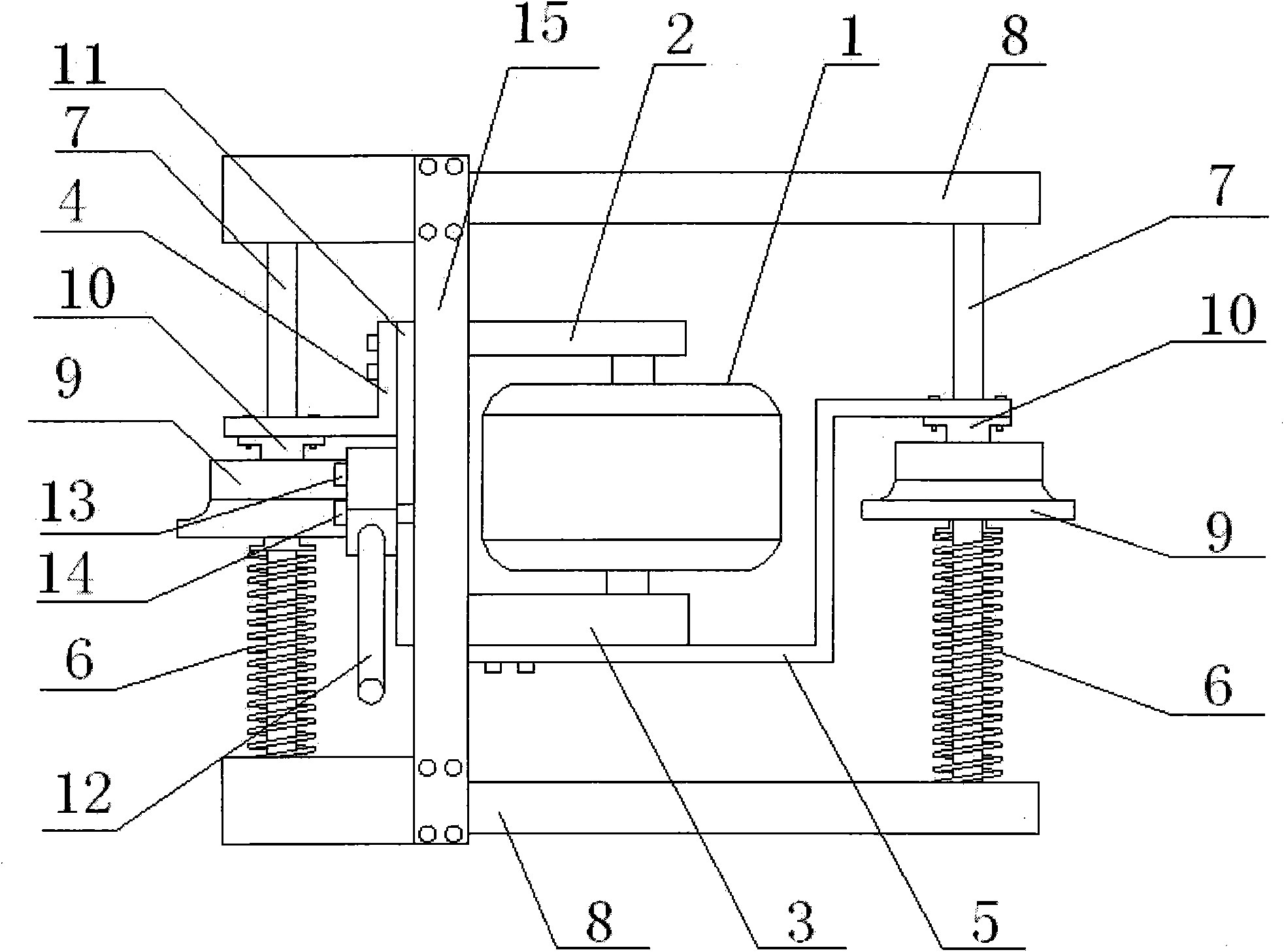

[0008] Such as figure 1 , 2 As shown, the portable rail flaw detection vehicle automatically adjusts the wheeled probe bracket, which includes front and rear rail travel wheels 9, wheel axles 7 respectively connected to the front and rear rail travel wheels, and an underframe 8 connected to the front and rear wheel axles. Connected between the front and rear axles 7 on the underframe, a probe bracket consisting of front and rear axle connecting plates, suspension beams, adjustment plates and fixing plates is provided, and one end and one side of the front side of the suspension beam 11 are fixedly connected to the front and rear axles respectively. Rear axle connecting plate 4,5, the other end of front and rear wheel axle connecting plate is connected with the axial sleeve 10 that is affixed on the front and rear rail traveling wheel 9 respectively. Both ends of the rear side of the suspension beam are fixedly connected to the adjusting plate 2 and the fixing plate 3 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com