Rubber part broaching machine for simple wire harness

A technology for hole reaming machines and rubber parts, applied in the field of hole reaming machines, can solve problems such as poor installation, lower production efficiency, complicated installation methods, etc., and achieve the effect of avoiding damage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

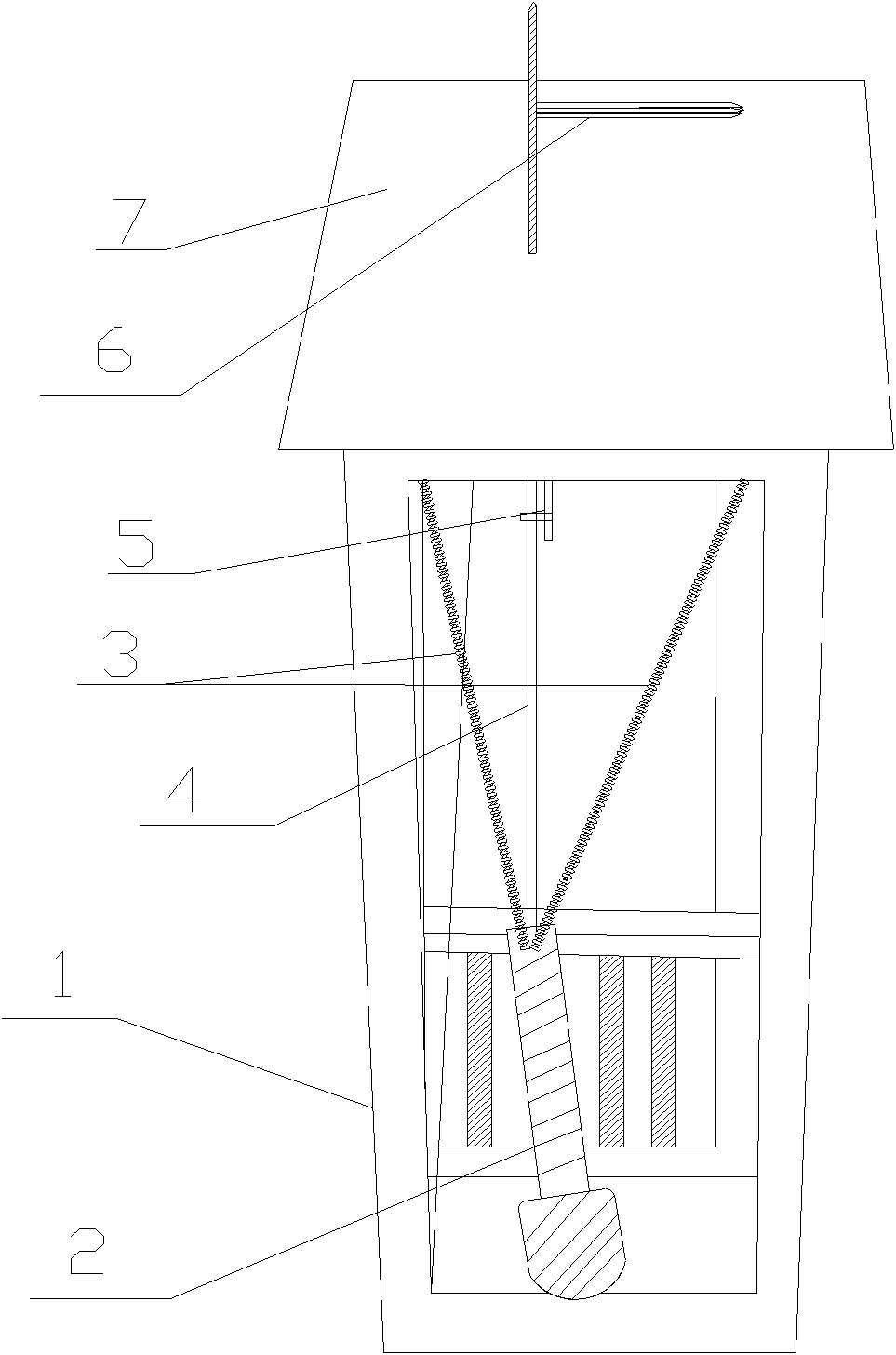

[0014] Such as figure 1 As shown, a simple reaming machine for rubber parts for wire harnesses, the reaming machine includes a support bracket 1, a work surface 7, a pedal 2, a pull rod 4, a reaming rod pull rod 5, a reaming rod 6, and a spring 3. The support bracket 1 is connected with the work surface 7 to form the main supporting part of the whole reaming machine. The pedal 2 is provided with the lower part of the support bracket 1 . One end of the spring 3 is connected with the pedal 2, and the other end of the spring 3 is connected with the support bracket 1 top. One end of pull bar 4 is hinged with pedal 2, and the other end of pull bar 4 is hinged with reaming rod pull bar 5. The reaming rod 6 includes two symmetrical parts, one of which is fixed to the work surface 7 and the other part is connected to the reaming rod pull rod 5 . When the reaming machine is in use, first apply force to the pedal 2 through an external force, so that it drives the pull rod 4 and pulls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com