Medium circulation system for exhaust heat indirect type temperature-difference thermoelectric device for marine diesel engine

A technology for marine diesel engines and thermoelectric devices, which is applied to exhaust devices, mufflers, mechanical equipment, etc., can solve the problem of inability to stabilize the temperature of the hot end of thermoelectric devices, difficult design and application of thermoelectric devices, and low utilization of engine exhaust waste heat. and other problems, to achieve the effect of preventing the temperature fluctuation and sudden change of the hot end, large power output, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

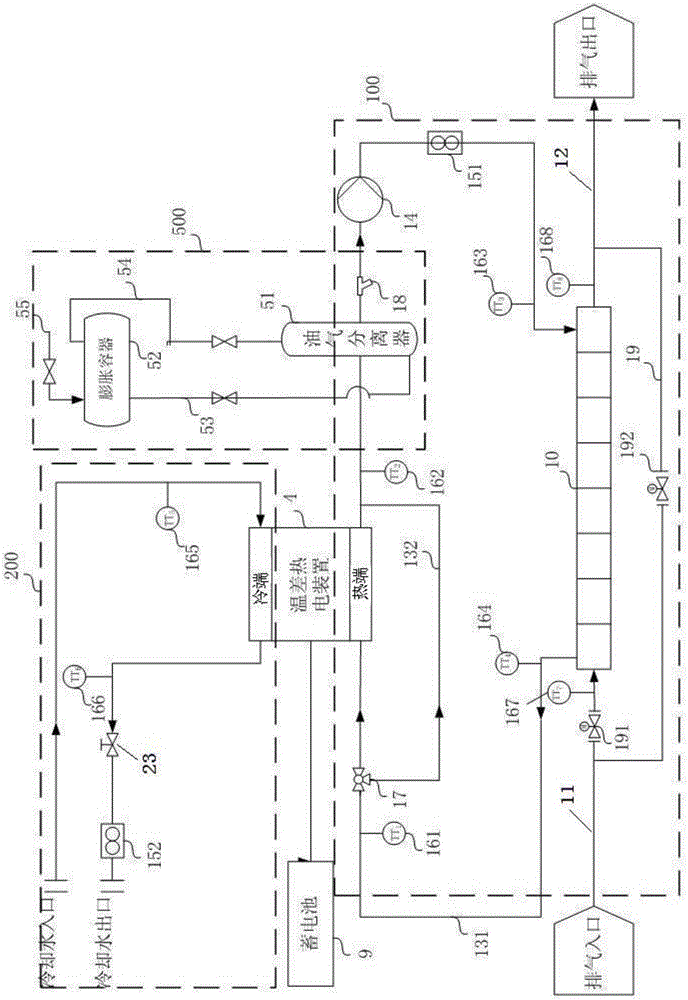

[0022] see figure 1 and figure 2 . According to an embodiment of the present invention, a medium circulation system of a marine diesel engine exhaust waste heat indirect thermoelectric device includes a hot end circulation unit 100 , a cold end circulation unit 200 and a controller 3 .

[0023] The hot end circulation unit 100 includes a gas-liquid heat exchanger 10 , an air inlet pipeline 11 , an air outlet pipeline 12 , and a heat transfer oil circulation pipeline that can deliver heat transfer oil to the hot end of the thermoelectric device 4 . The heat transfer oil circulation pipeline is composed of a main circulation pipeline 131 and a bypass pipeline 132 .

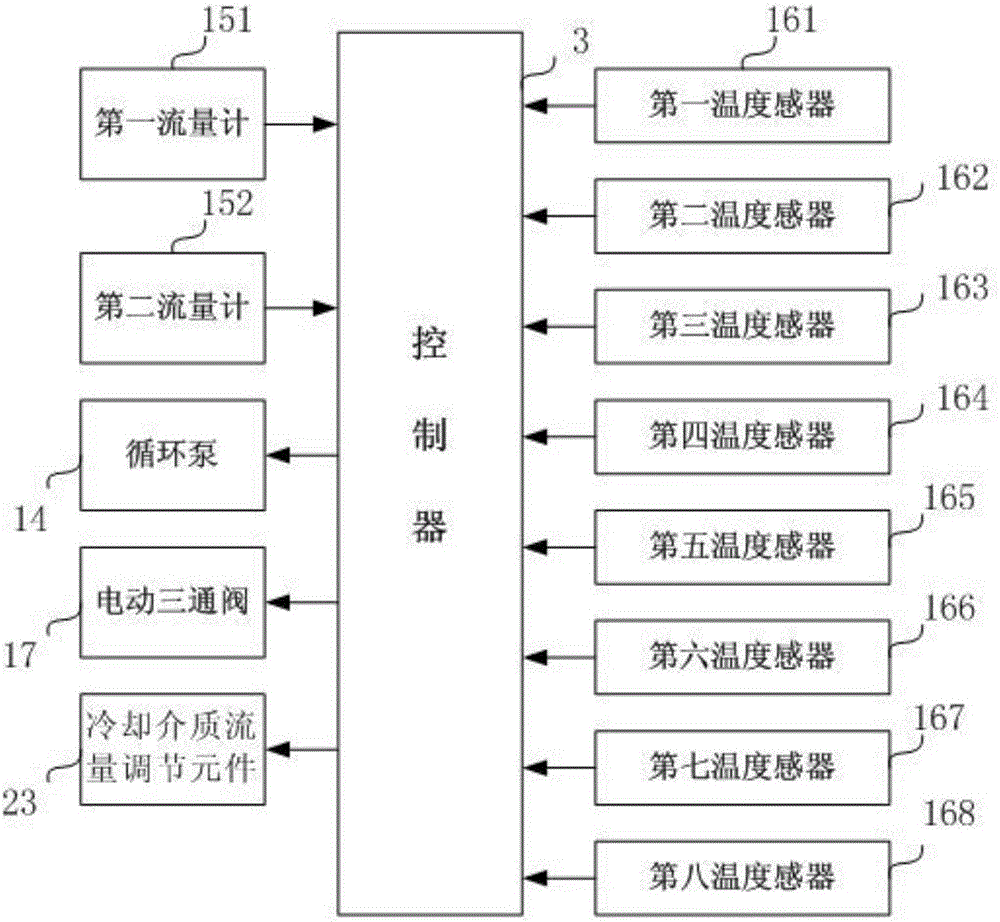

[0024] A circulation pump 14 , a first flow meter 151 , a first temperature sensor 161 , a second temperature sensor 162 , a third temperature sensor 163 , a fourth temperature sensor 164 , an electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com