Cylindrical electric core flat angle pressing clamp

A cell and fixture technology, applied in the field of cylindrical cell processing tools, can solve the problems of rising product cost, low processing efficiency, and high defective product rate, and achieve the effect of improving production efficiency and avoiding low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

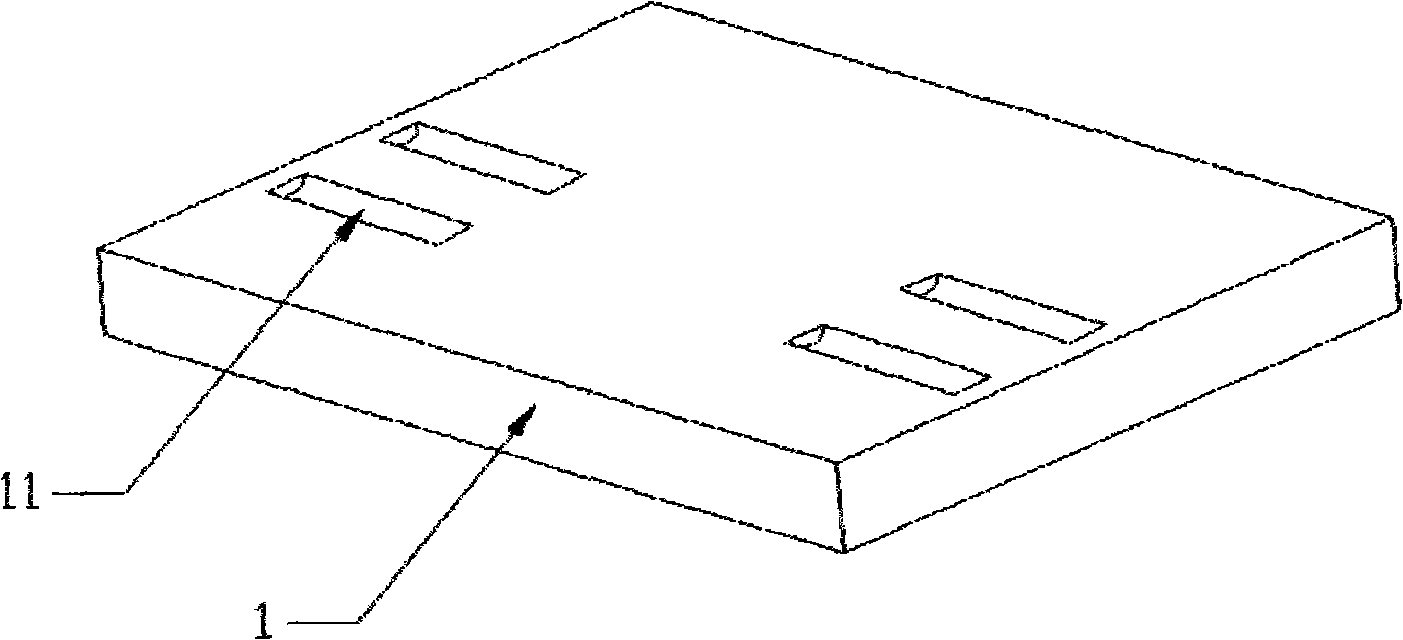

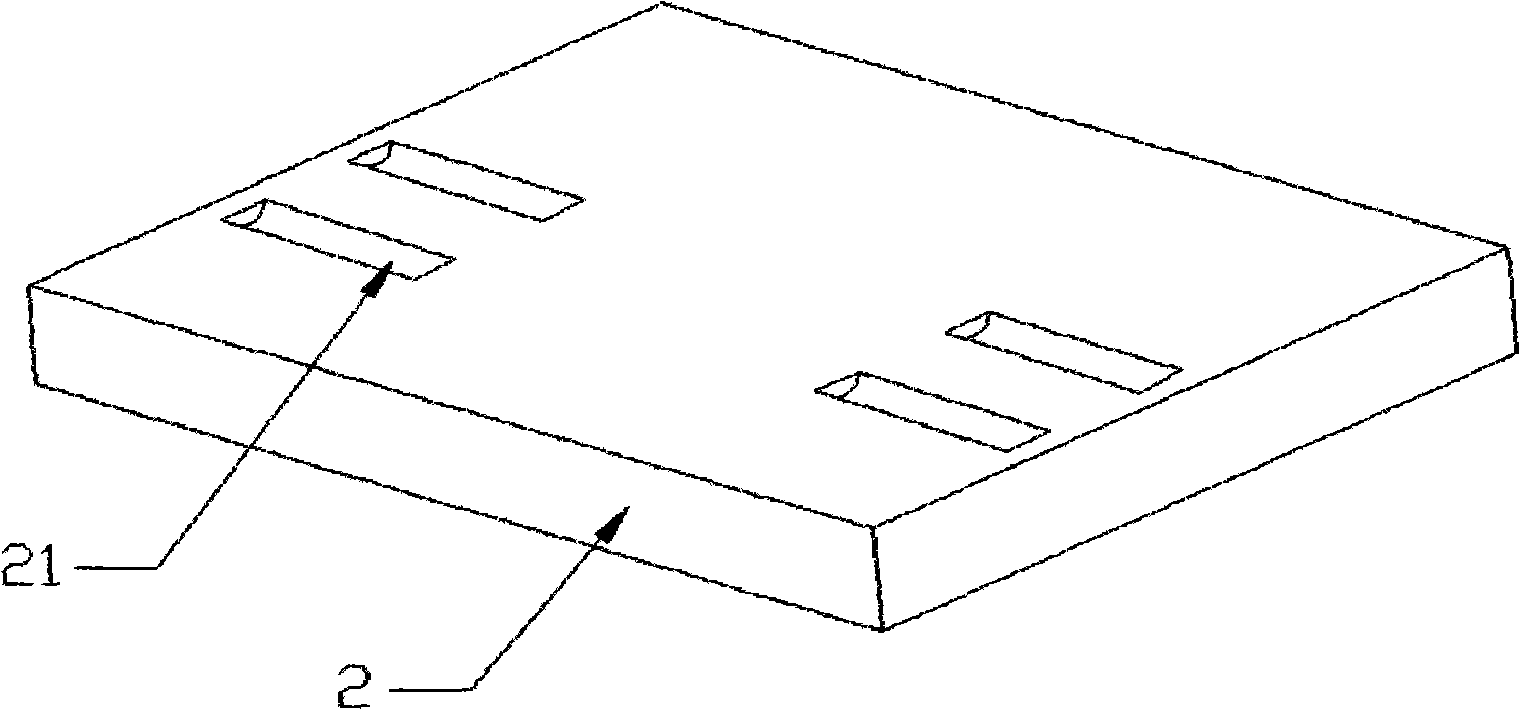

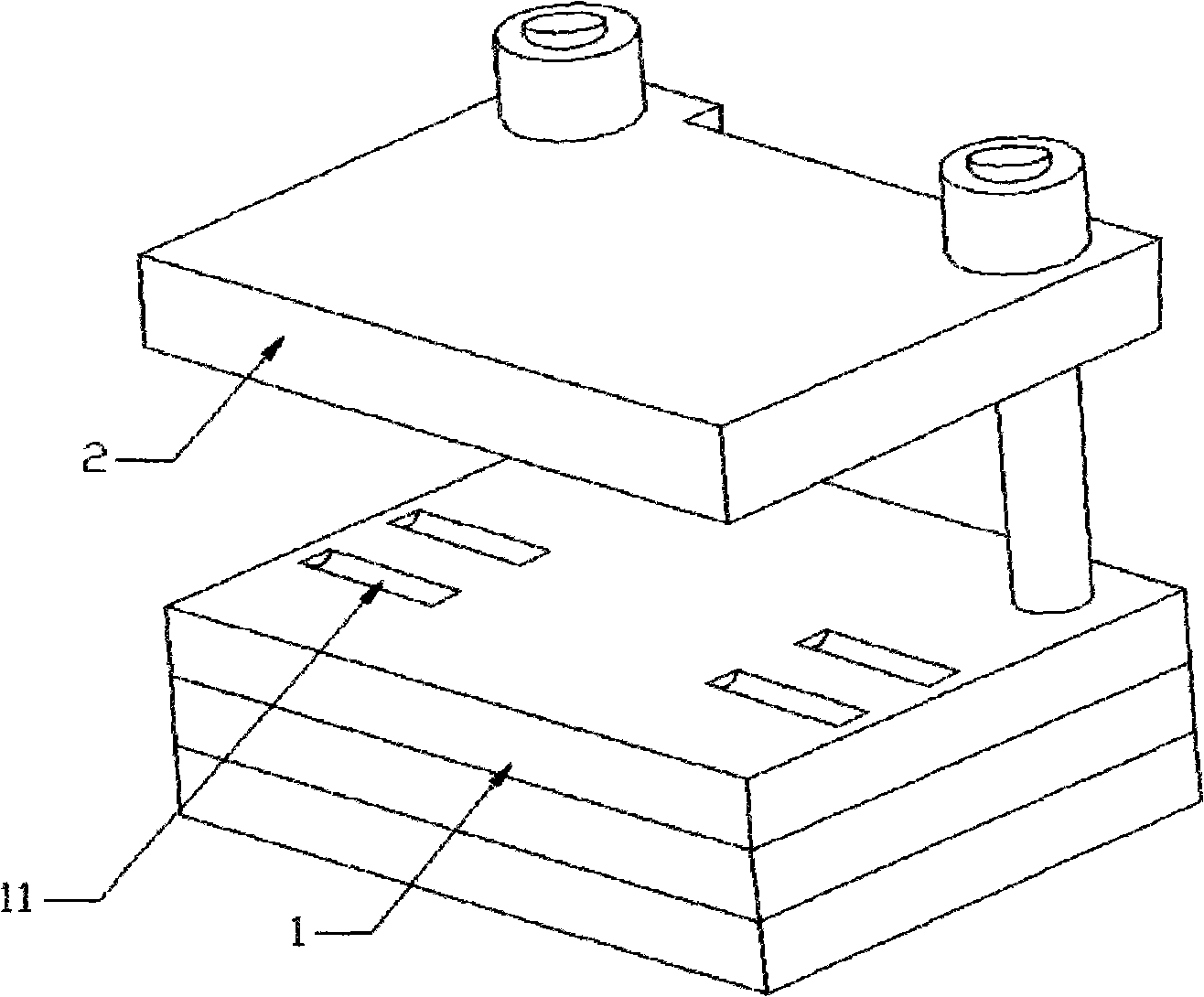

[0016] Such as figure 1 and figure 2 As shown, the cylindrical battery cell flattening angle jig of this embodiment includes a battery cell carrying platform. The cell carrying platform 1 is provided with a semi-cylindrical cell placement groove 11, and a pressing force is provided above the cell carrying platform 1. Table 2, the lower surface of the pressing table 2 corresponds to the position of the cell placement groove 11, and the cell pressing groove 21 matched with the cell placement groove 11 is provided, and the battery placement groove 11 cooperates with the cell pressing groove 21 to form a cylinder After the pressing table 2 is pressed down and contacts the battery carrying platform 1, it is flatly fitted except the battery placement groove 11 and the battery pressing groove 21, and the battery placement groove 11 and the battery The flat joints at both ends of the core pressing groove 21 flatten the openings at both ends of the cell.

[0017] In the actual produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com