Novel filter capable of measuring liquid flow rate and continuously working

A liquid flow and filter technology, which is used in fixed filter element filters, electromagnetic flowmeters to detect fluid flow, volume/mass flow generated by electromagnetic effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

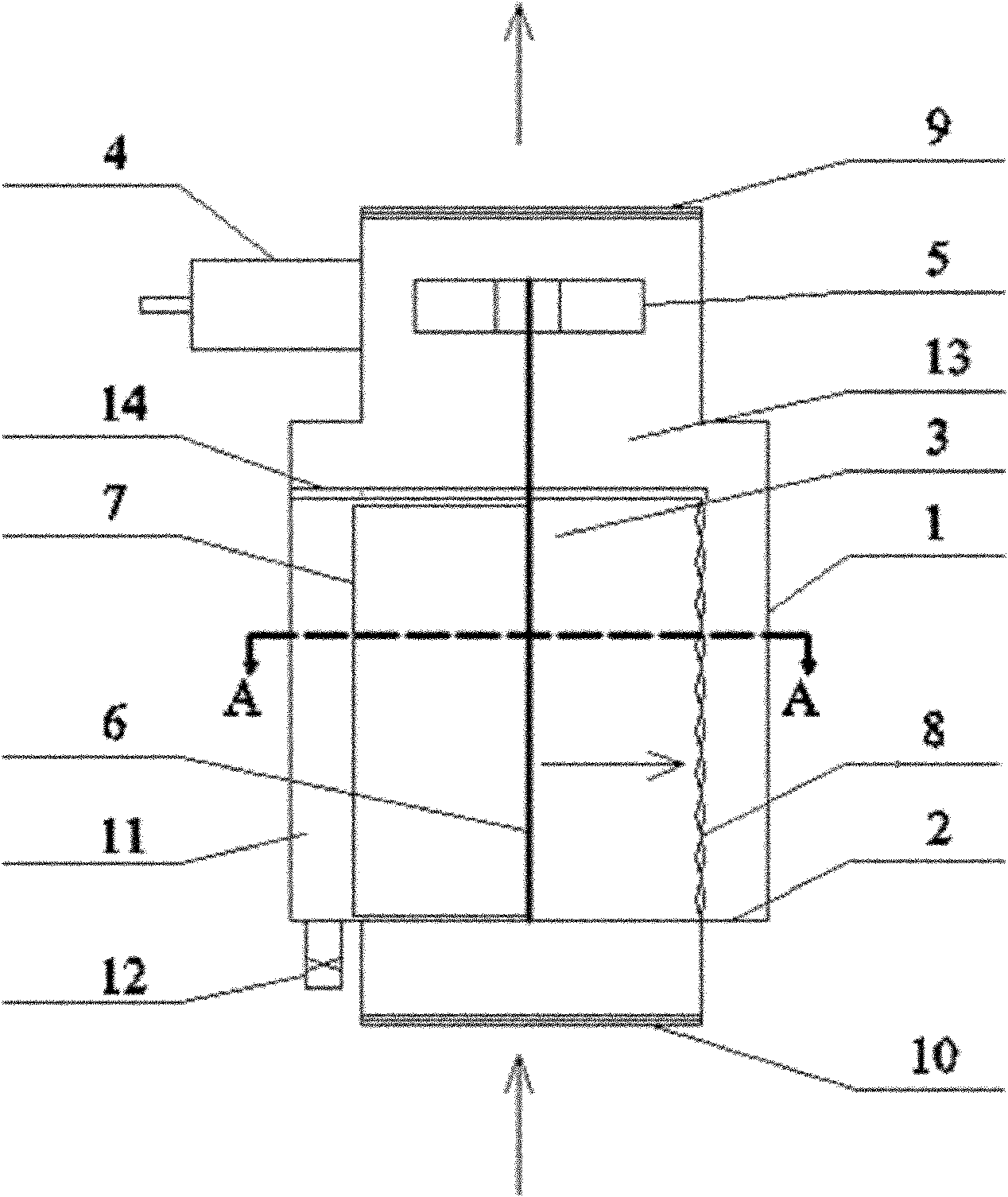

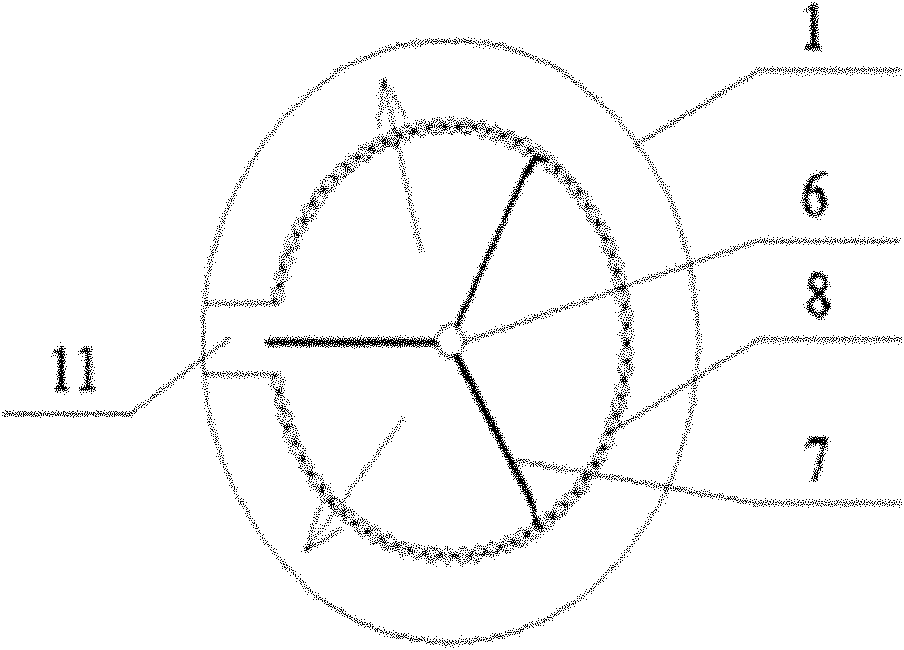

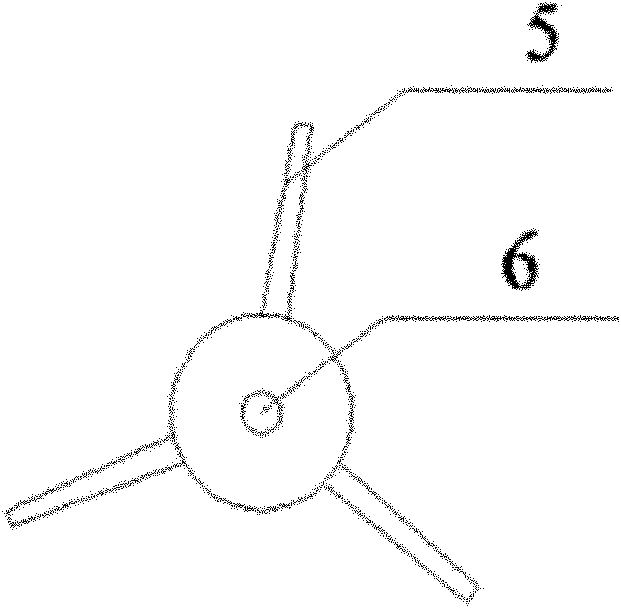

[0021] This embodiment includes a filter body 1 , a bottom plate 2 , an inner core 3 , and an electromagnetic induction signal device 4 . Inner core 3 is made up of impeller 5, rotating shaft 6, scraper 7, filter screen 8, is connected as a whole with rotating shaft as the center, goes deep into from the bottom of meter body during installation, directly be stuck on the positioning groove 14 on the side of meter body. The body 1 and the inner core 3 form two spaces to separate the fluid from the impurities. The fluid flows out from around the filter screen 8 into the fluid area 13 , and the impurities enter into the impurity area 11 .

[0022] There is a fluid inlet 10 and a control valve 12 on the bottom plate 2, and the fluid outlet 9 is on the top of the meter body. The fluid inlet 10 and the fluid outlet 9 are connected with the water pipes at both ends of the meter body by threaded buckles. After the fluid flows from the fluid inlet 10 through the filter screen 8, impuri...

Embodiment 2

[0025] This embodiment includes a filter body 1 , a bottom plate 2 , an inner core 3 , and an electromagnetic induction signal device 4 . Inner core 3 is made up of impeller 5, rotating shaft 6, scraper 7, filter screen 8, is connected as a whole with rotating shaft as the center, goes deep into from the bottom of meter body during installation, directly be stuck on the positioning groove 14 on the side of meter body. The body 1 and the inner core 3 form two spaces to separate the fluid from the impurities. The fluid flows out from around the filter screen 8 into the fluid area 13 , and the impurities enter into the impurity area 11 .

[0026] There is a fluid inlet 10 and a control valve 12 on the bottom plate 2, and the fluid outlet 9 is on the top of the meter body. The fluid inlet 10 and the fluid outlet 9 are connected with the water pipes at both ends of the meter body by threaded buckles. After the fluid flows from the fluid inlet 10 through the filter screen 8, impuri...

Embodiment 3

[0029]This embodiment includes a filter body 1 , a bottom plate 2 , an inner core 3 , and an electromagnetic induction signal device 4 . Inner core 3 is made up of impeller 5, rotating shaft 6, scraper 7, filter screen 8, is connected as a whole with rotating shaft as the center, goes deep into from the bottom of meter body during installation, directly be stuck on the positioning groove 14 on the side of meter body. The body 1 and the inner core 3 form two spaces to separate the fluid from the impurities. The fluid flows out from around the filter screen 8 into the fluid area 13 , and the impurities enter into the impurity area 11 .

[0030] There is a fluid inlet 10 and a control valve 12 on the bottom plate 2, and the fluid outlet 9 is on the top of the meter body. The fluid inlet 10 and the fluid outlet 9 are flanged to the water pipes at both ends of the meter body. After the fluid flows from the fluid inlet 10 through the filter screen 8, impurities remain on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com