Chamfering method of optical lens for camera

A technology of optical lenses and cameras, which is applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problem that chamfering cannot be produced in batches, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

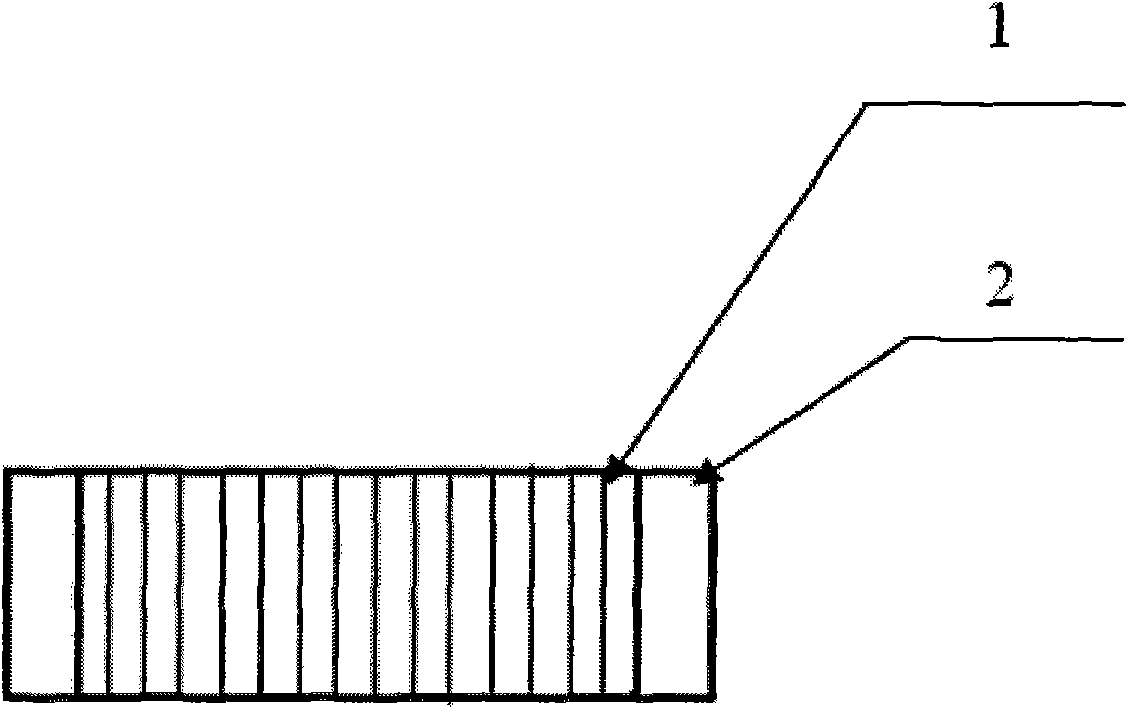

[0030] Step 1: Evenly stack multiple lenses (1) to be edged, place two pieces of ordinary glass (2) at both ends, and then place them in a container with wax, so that the wax can completely soak into the gap between the lenses , bond a plurality of lenses to form a lens column, if it is a disc, grind the lens column into a cylinder to form a cylindrical lens column, such as figure 1 .

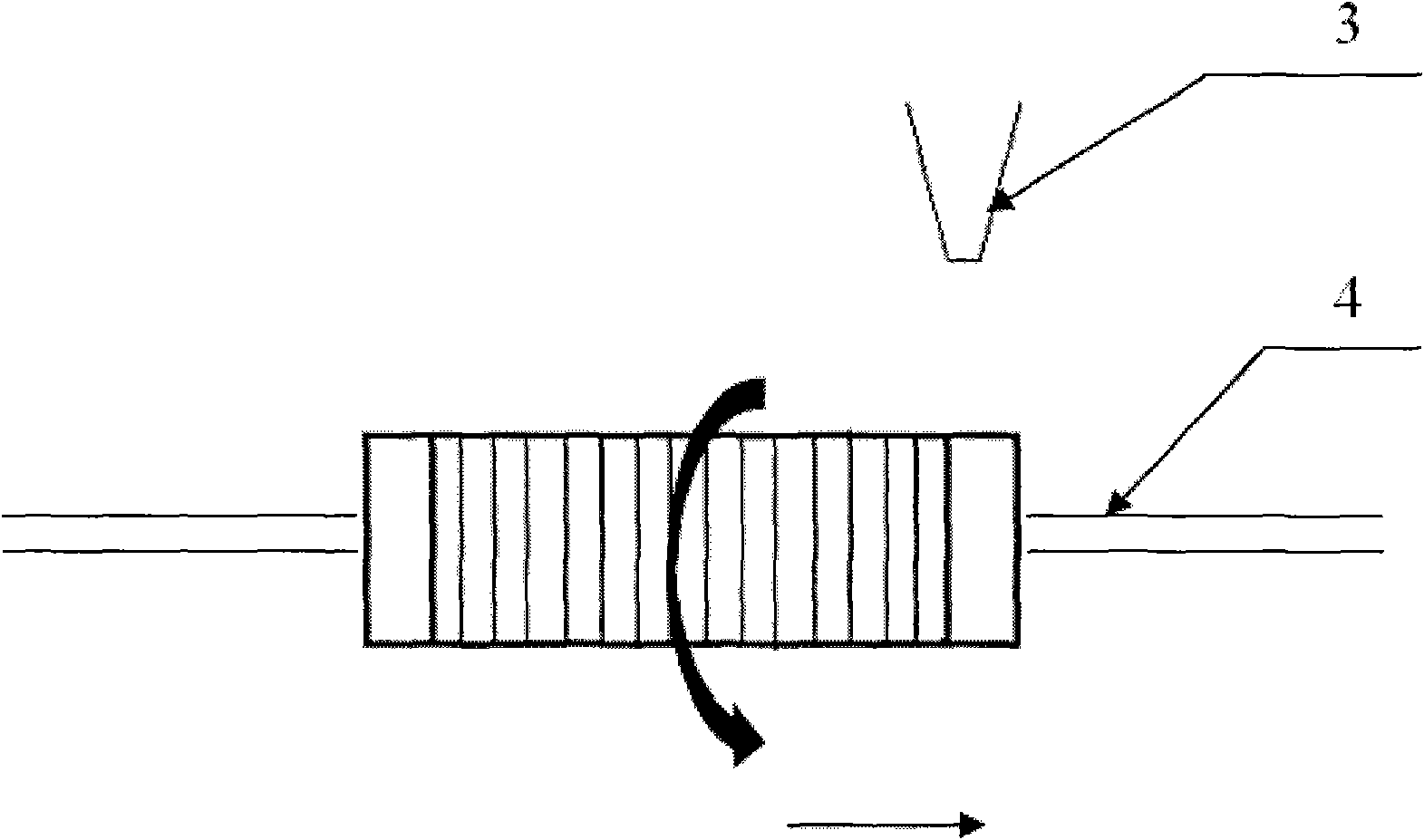

[0031] Step 2: Lift both ends of the lens column with thimbles (4), the middle is hollow, and make it rotate at a high speed around the horizontal line where the thimble (3) is located, and move horizontally evenly at the same time, as figure 2 .

[0032] Step 3: Use a high-pressure spray gun (4) to evenly spray emery onto the lens column. After spraying, the lens and the wax sticky area are sprayed into a "V" shape to form a chamfered lens (11), such as Figure 4 . The water-sand mixture is used for spraying. The water can cool the heat generated during spraying, and can take away the glas...

Embodiment 2

[0034] In Embodiment 1, the lens column is used to rotate at a high speed with the horizontal line where the thimble is located as the axis, and at the same time move horizontally evenly. This embodiment makes the following improvements to Step 2 and Step 3 in Embodiment 1:

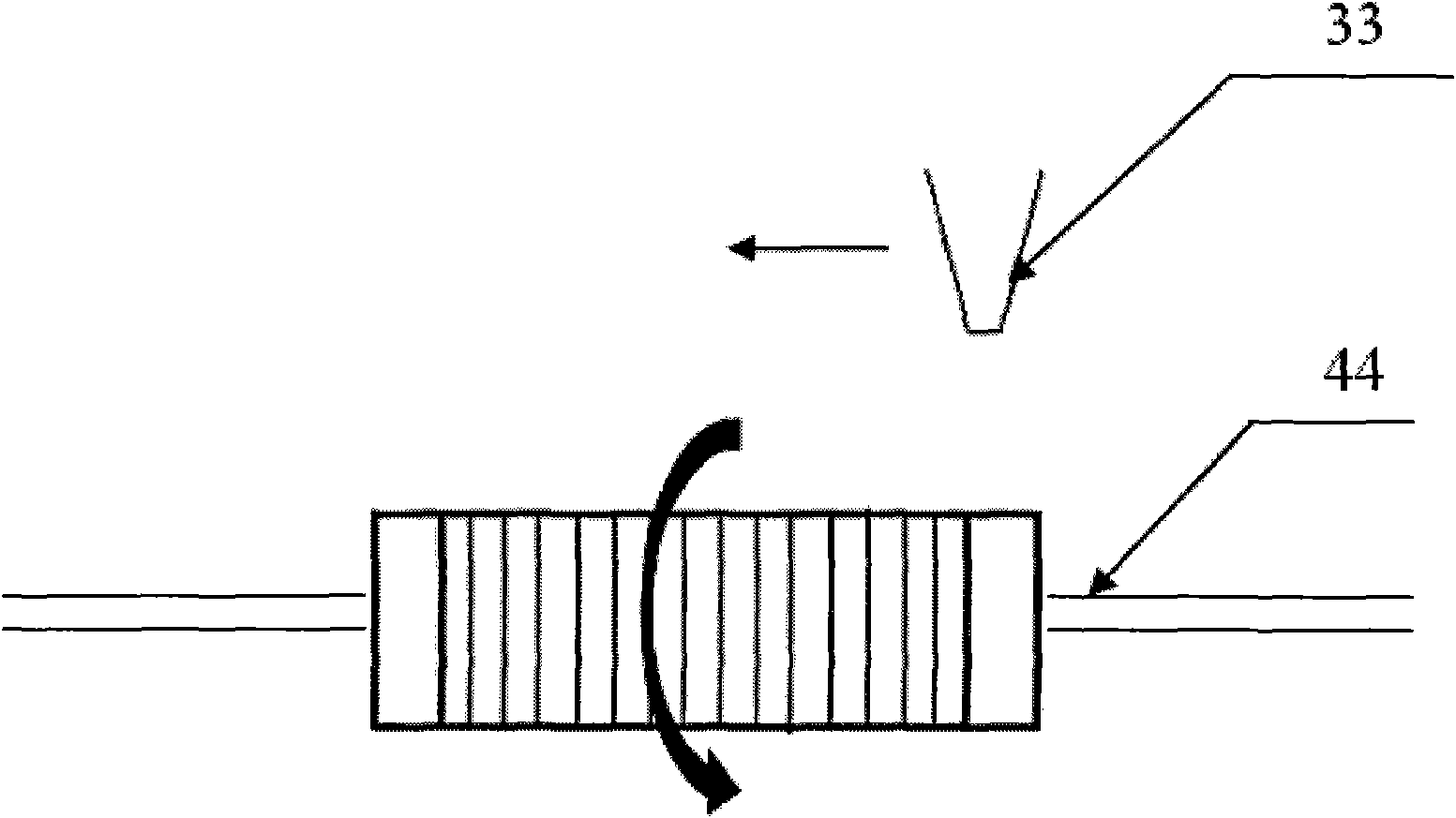

[0035] Step 2: Lift the two ends of the lens column with thimbles (44), the middle is hollow, and make it rotate at high speed along the horizontal line where the thimble is located, and the horizontal direction is stationary, such as image 3 .

[0036] Step 3: Use the high-pressure spray gun (33) to evenly spray the corundum on the lens column, and at the same time, the high-pressure spray gun (33) moves evenly horizontally, such as image 3 . The corundum collides with the lens column, and after spraying, the lens and the wax sticky place are sprayed into a "V" shape, forming a chamfer. The water-sand mixture is used for spraying. The water can cool the heat generated during spraying, and can take aw...

Embodiment 3

[0038] In order to further improve the production efficiency and the smoothness of the surface of the lens column, the step 1 in the embodiment 1 is improved as follows:

[0039] Step 1: Directly bond a plurality of large lenses to be processed and cut them into lens cylinders of required size as a whole. In this step, cutting a plurality of large pieces as a whole greatly improves the production efficiency, and at the same time, the surface of the lens column cut as a whole is smooth, and it is easier to chamfer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com