Film deposition device

A film deposition and control device technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of processing chamber pollution and hindering processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

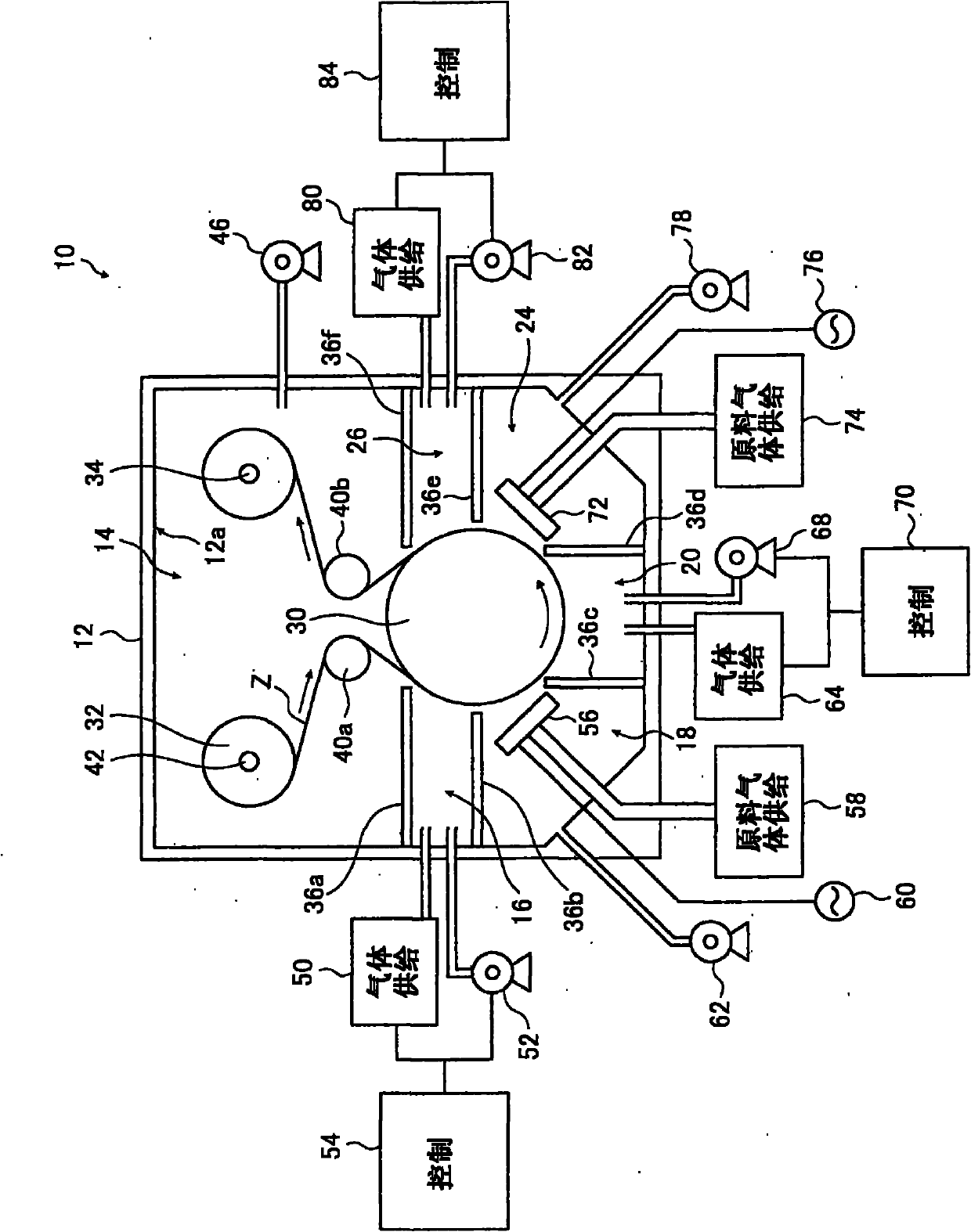

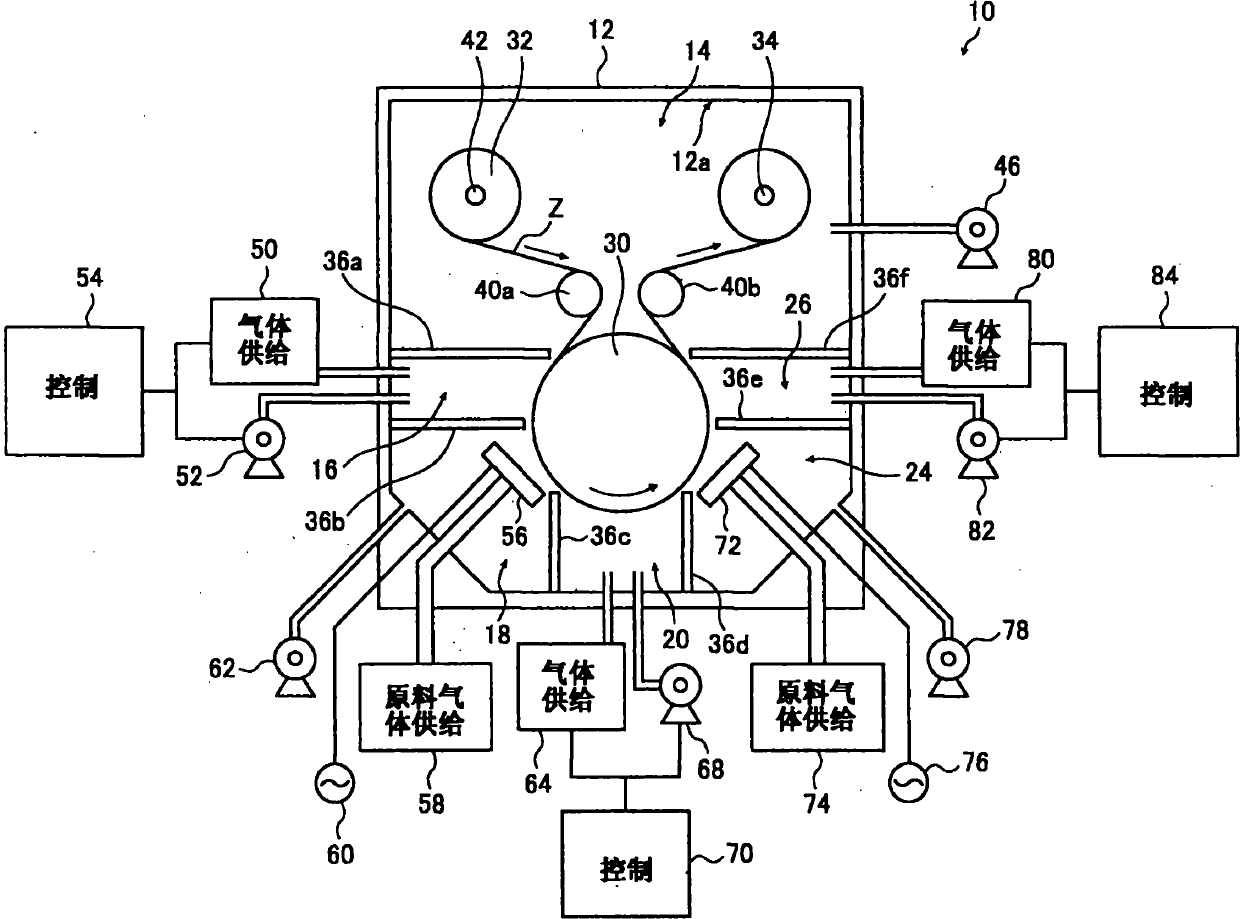

[0127] exist figure 1 The film deposition apparatus 10 shown in is used to deposit a silicon nitride film on a substrate Z.

[0128] The substrate Z used was a PET film (Cosmoshine A4300 available from Toyobo Co., Ltd.).

[0129] Silane gas (flow rate of 100 sccm), ammonia gas (flow rate of 100 sccm) and nitrogen gas (flow rate of 800 sccm) were used as raw material gases to form a silicon nitride film by CCP-CVD. The gas used to supply to the differential pressure chamber was nitrogen (flow rate: 1000 sccm).

[0130] The film deposition pressures of the first film deposition chamber 18 and the second film deposition chamber 24 were set to 30Pa and 20Pa, respectively, and the first differential pressure chamber 16 and the second differential pressure chamber 20 were set to a pressure of 35Pa, while the The third differential pressure chamber 26 is set at a pressure of 25 Pa.

[0131] In addition, the power source used was an RF power source with a frequency of 13.56 MHz and...

Embodiment 2 and 3 and comparative example 1

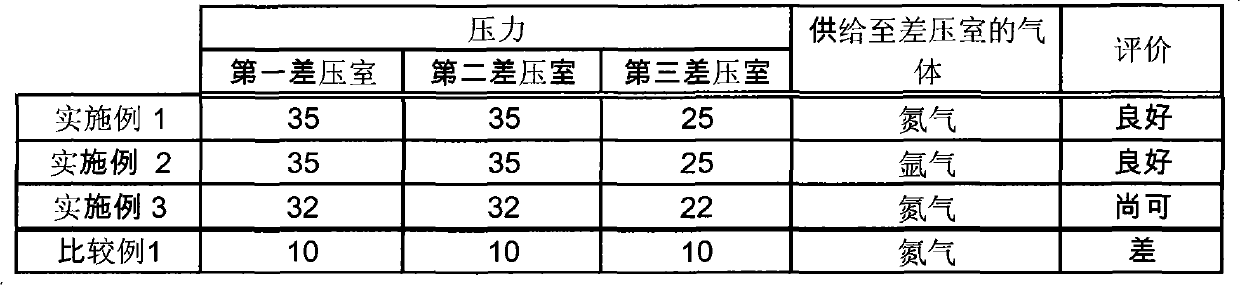

[0134] In Example 2, Example 1 was repeated except that argon gas was introduced into the differential pressure chamber to form a silicon nitride film on a substrate Z having a length of 1000 m, and three differential pressures were visually inspected and evaluated interior of the room.

[0135] In Embodiment 3, in addition to adjusting the amount of evacuation of each differential pressure chamber by the vacuum device to adjust the pressure of the first differential pressure chamber 16 and the second differential pressure chamber 20 to 32Pa, and to adjust the pressure of the third differential pressure chamber The chamber 26 was adjusted out of 22 Pa, Example 1 was repeated, a silicon nitride film was formed on the substrate Z having a length of 1000 m, and the insides of the three differential pressure chambers were visually inspected and evaluated.

[0136] In Comparative Example 1, in addition to adjusting the amount of evacuation of each differential pressure chamber by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com