Single push-and-pull window frame section with sealing joint surfaces and slide rail combined surfaces

A frame profile and slideway technology, which is applied in the field of single sliding window frame profiles, can solve the problems of difficult maintenance, falling corners of window sashes, and poor sealing, achieving good water blocking and sealing effects, and overcoming poor sealing effects. , easy push and pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

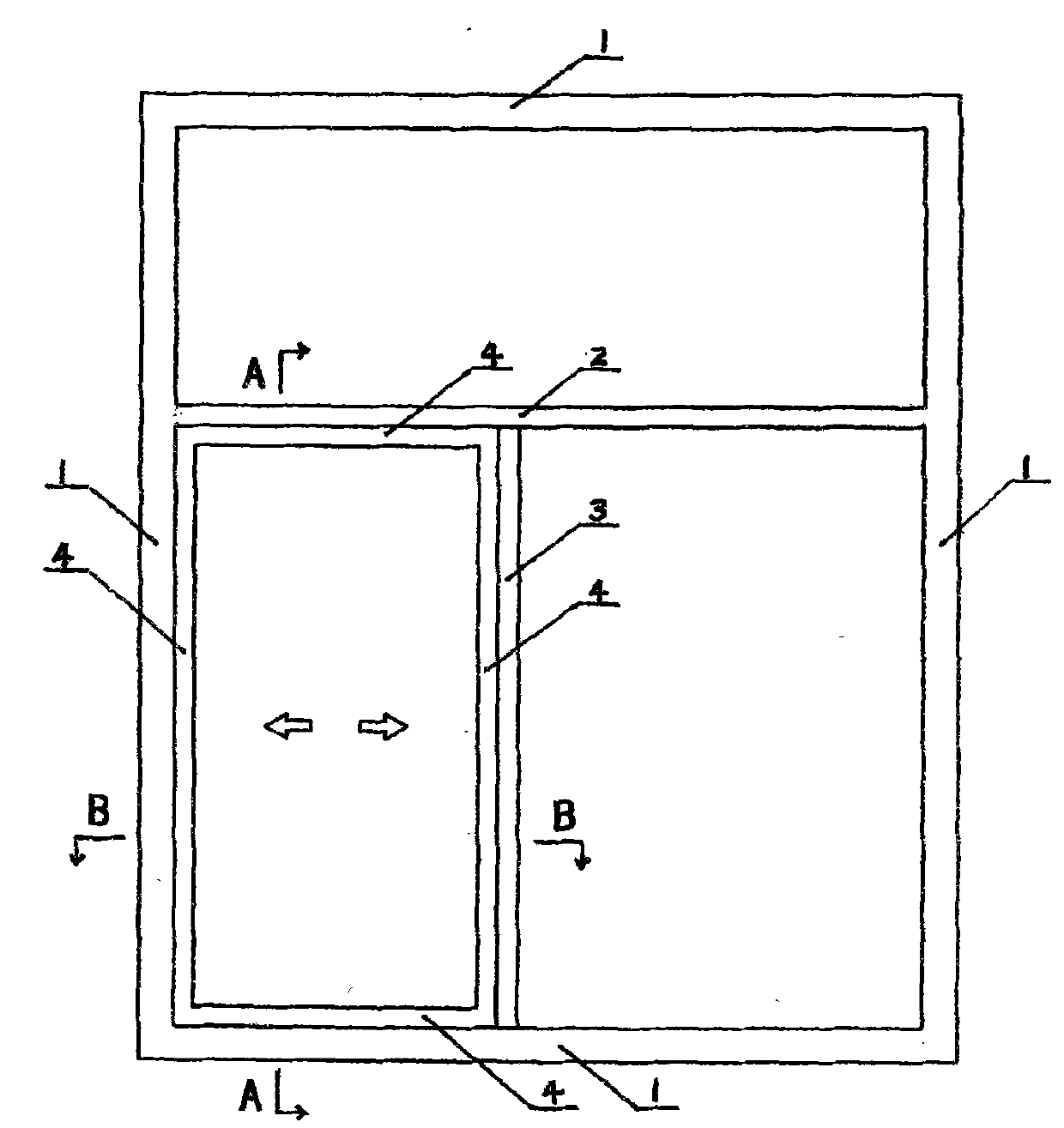

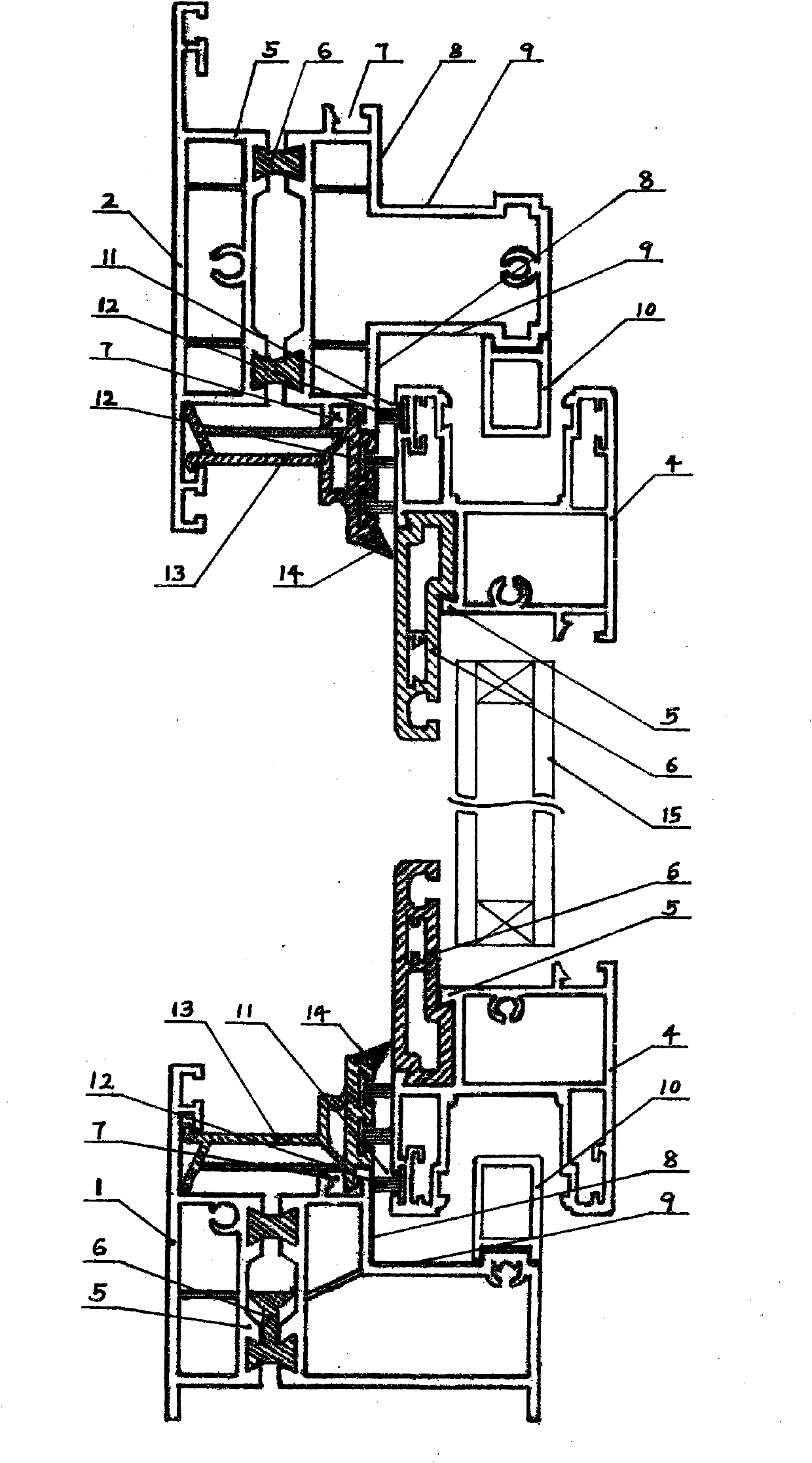

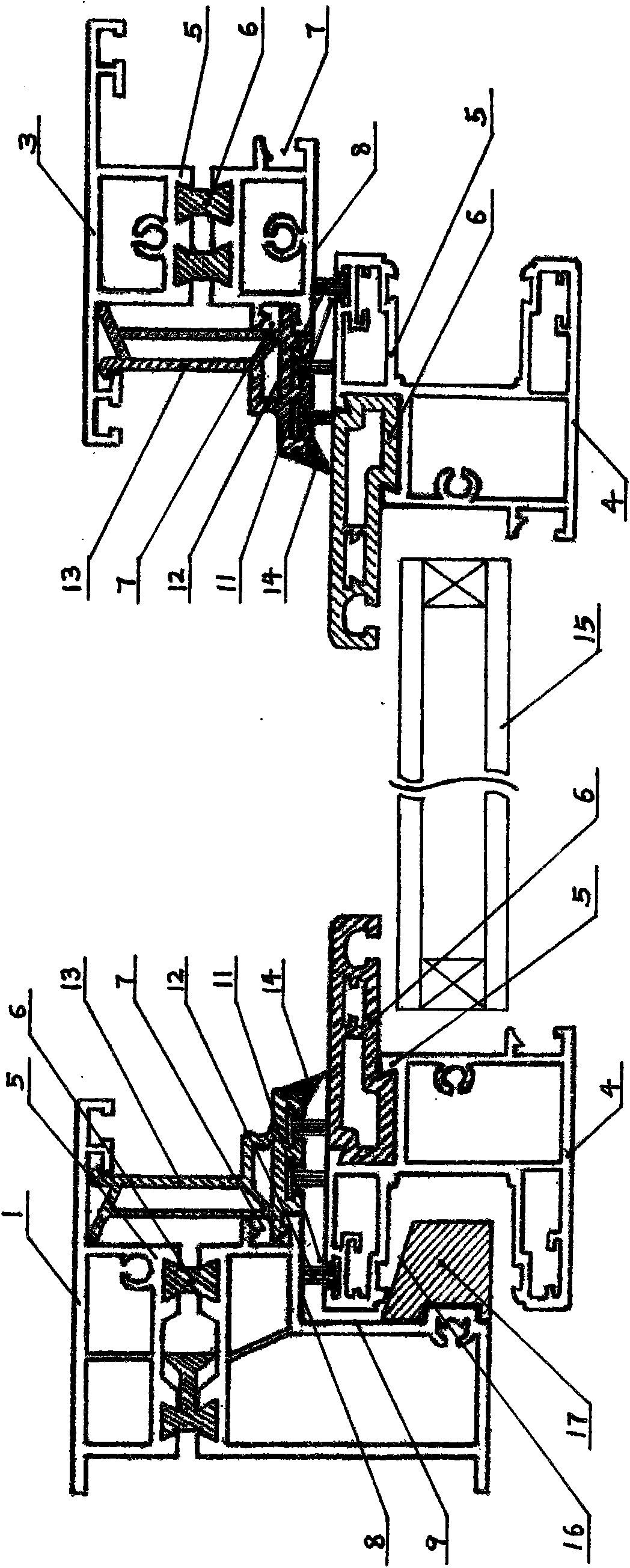

[0011] Embodiment 1, with reference to attached Figure 1~3 , a single push-pull window frame profile with a sealing abutment surface and a sliding track combination surface includes a frame profile 1, a stile frame profile 2, a small stile profile 3, a fan profile 4, a sealing strip 13, and a slideway strip 10, Use the frame profile 1, the stile frame profile 2, and the small stile profile 3 to make the window frame, and use the fan 4 profile to make the window sash, and the frame profile 1 and the stile frame profile 2 on the window frame within the corresponding range of the four sides of the sash 1. The glass bead opening 7 of the small stile profile 3 is combined with a sealing strip 13, and the lower plane of the stile frame profile 2 corresponding to the upper and lower sides of the window sash and the upper plane slideway combination surface 9 of the lower frame profile 1 are assembled and connected through the entire length. Long slideway bar 10, when the sash is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com