Dust removal device for electrical engineering based on spray mechanism and its use method

A technology of electrical engineering and dust removal device, which is applied in the field of electrical engineering, can solve the problems of dust pollution environment, low dust removal efficiency, secondary pollution, etc., and achieve the effect of ensuring the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

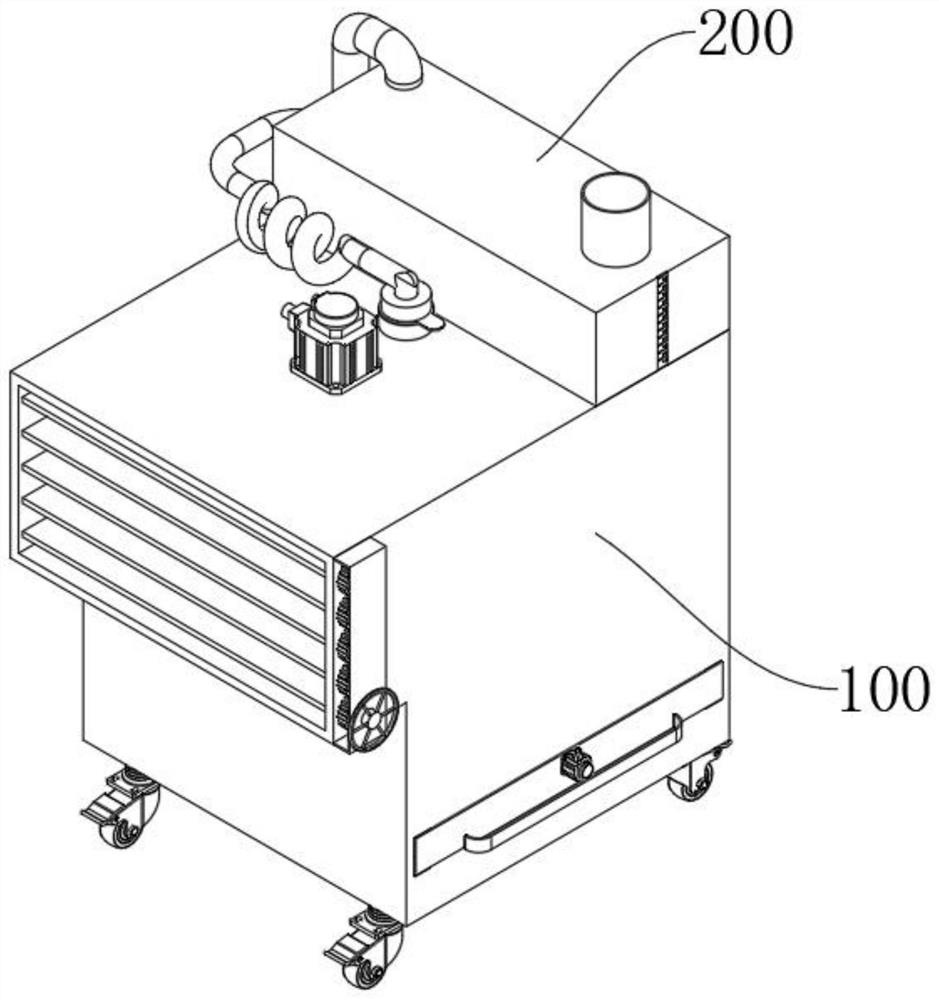

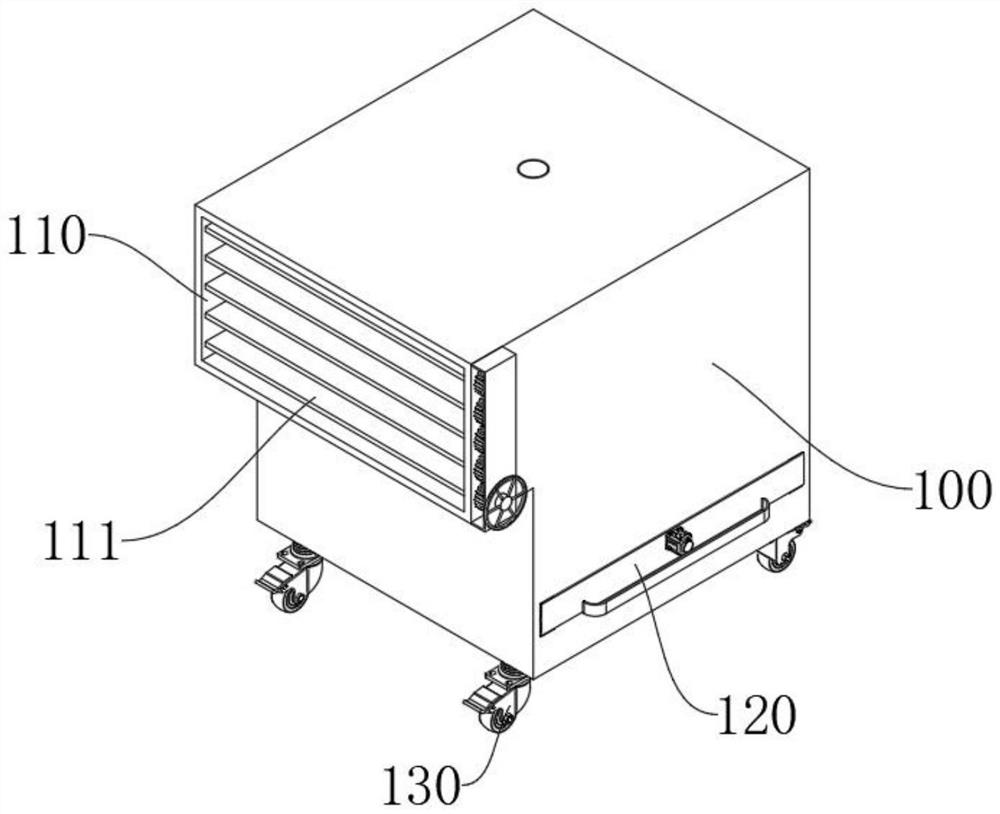

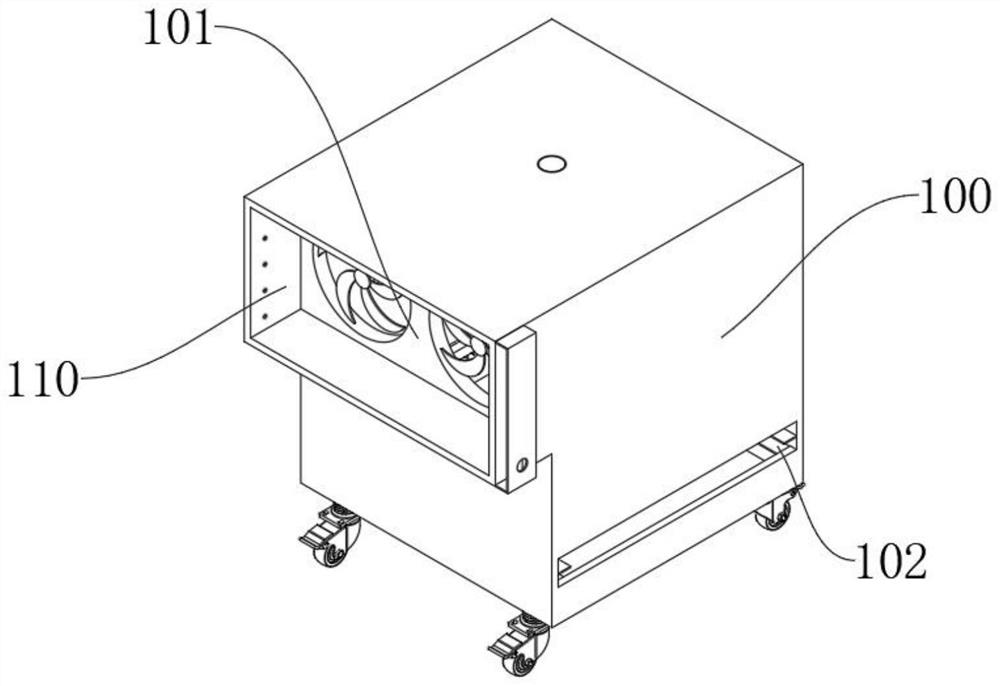

[0063] see Figure 1-Figure 15 As shown, this embodiment provides a dust removal device for electrical engineering based on a spray mechanism, including a dust box 100 and a spray mechanism 200 at the top of the dust box 100. The outer wall of the dust box 100 near the top is connected with a dust inlet 110, and the spray mechanism 200 including at least:

[0064] The water tank 210 is located on the top of the dust removal box 100. The water tank 210 is made of transparent plastic material. The top of the water tank 210 is connected with a water adding pipe 211. The water in the water tank 210 is kept sufficient, which is convenient for subsequent spraying of dust inside the dust removal box 100, which is beneficial to the dust reduction effect. The outer wall of the water tank 210 is provided with a scale 212. fully utilized;

[0065] When the water tank 210 in this example is in use, the water content in the water tank 210 is observed through the scale 212. When the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com