Long glass fiber filling quantity measuring method in plastic modification processing process

A long glass fiber, processing technology, applied in the field of long glass fiber filling measurement, can solve the problems of energy consumption, large measurement error, material loss, etc., and achieve the effect of improving processing efficiency, simple measuring tools, and short measuring cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

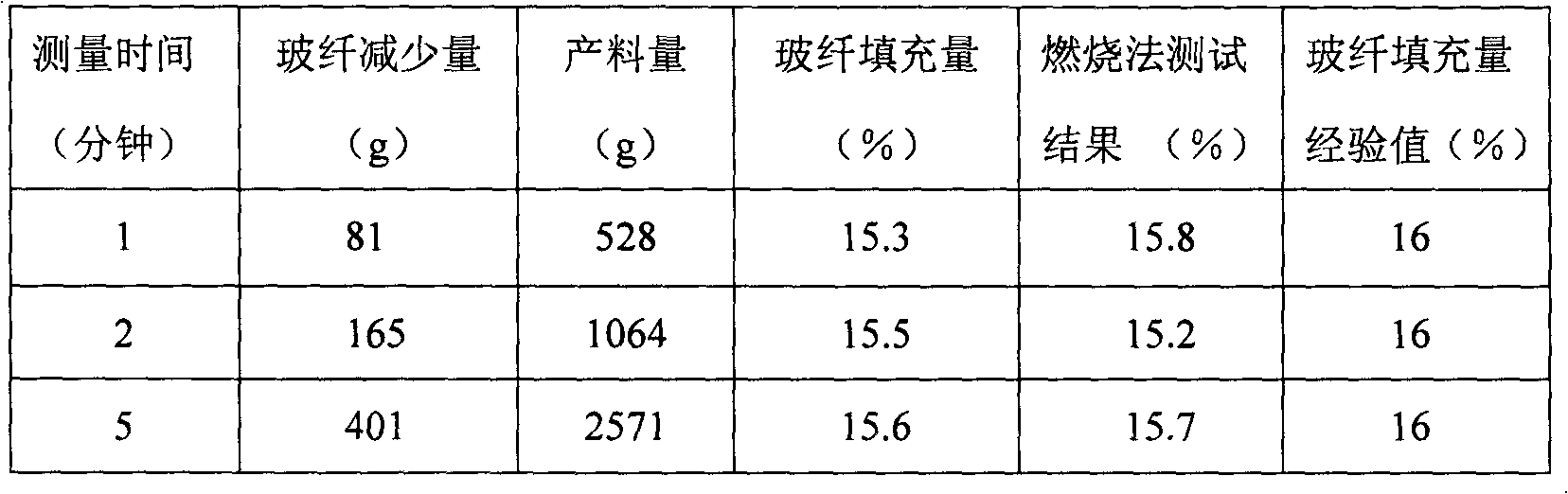

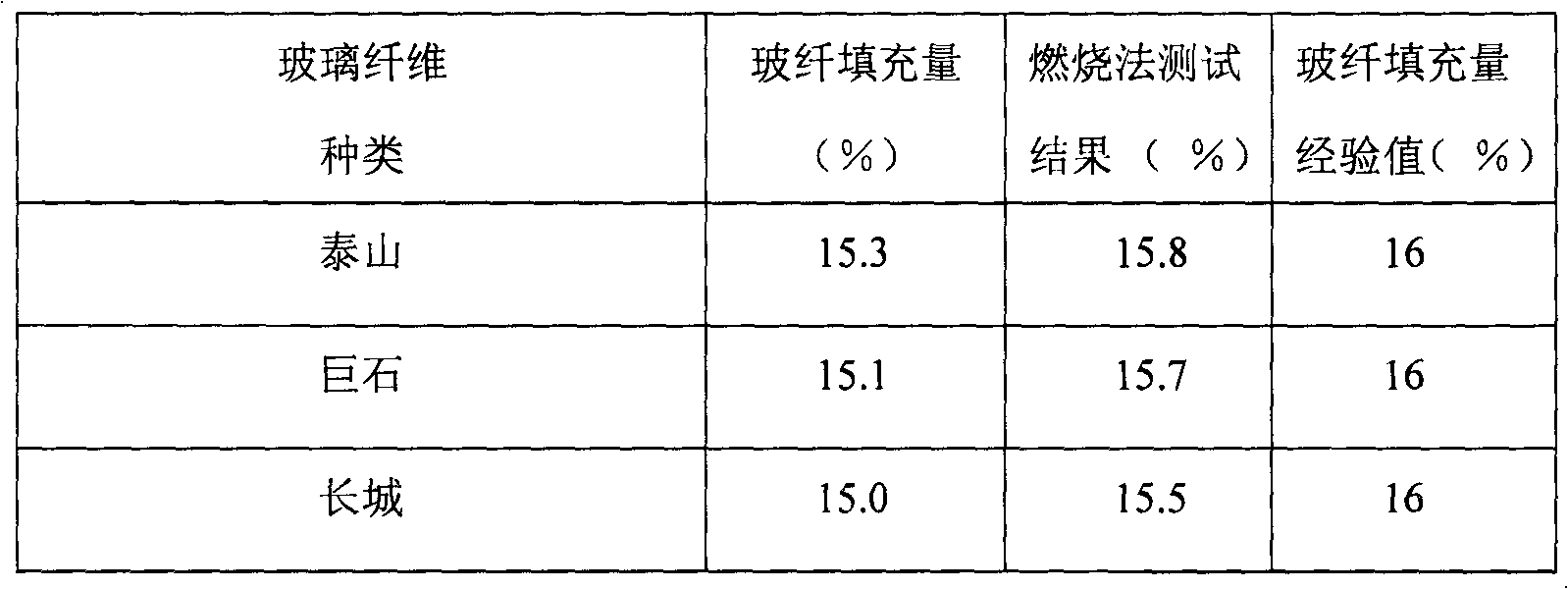

[0025] Put the PET chips in the twin-screw extruder, set the process parameters of the extruder, and then turn on the machine for extrusion and granulation. The long glass fibers are added from the glass fiber feeding port of the twin-screw extruder. The number of strands added for 1 share. After the material strip is pulled smoothly, keep all the processing parameters unchanged, place the glass fiber on the electronic scale, measure the same sampling time with a chronograph stopwatch for 1 minute, and record the weight reduction of the long glass fiber within 1 minute. At the same time, at the feed port of the twin-screw extruder, the feed was fed for 1 minute, and the weight of the feed was weighed with an electronic scale. Then divide the long glass fiber reduction by the material weight to get the long glass fiber filling, and compare it with the empirical value and the combustion test value. The long glass fiber is the long glass fiber produced by Taishan Glass Fiber Co....

Embodiment 2

[0027] Basically the same as embodiment 1, the difference is: the same sampling time measured by the chronograph stopwatch is 2 minutes.

Embodiment 3

[0029] Basically the same as embodiment 1, the difference is: the same sampling time measured by a chronograph stopwatch is 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com