Method for aligning a cutter spindle of a granulator and granulator for producing plastic granulate

A granulator and cutter shaft technology, applied in metal processing and other directions, can solve problems such as tool wear, achieve optimal positioning and avoid downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

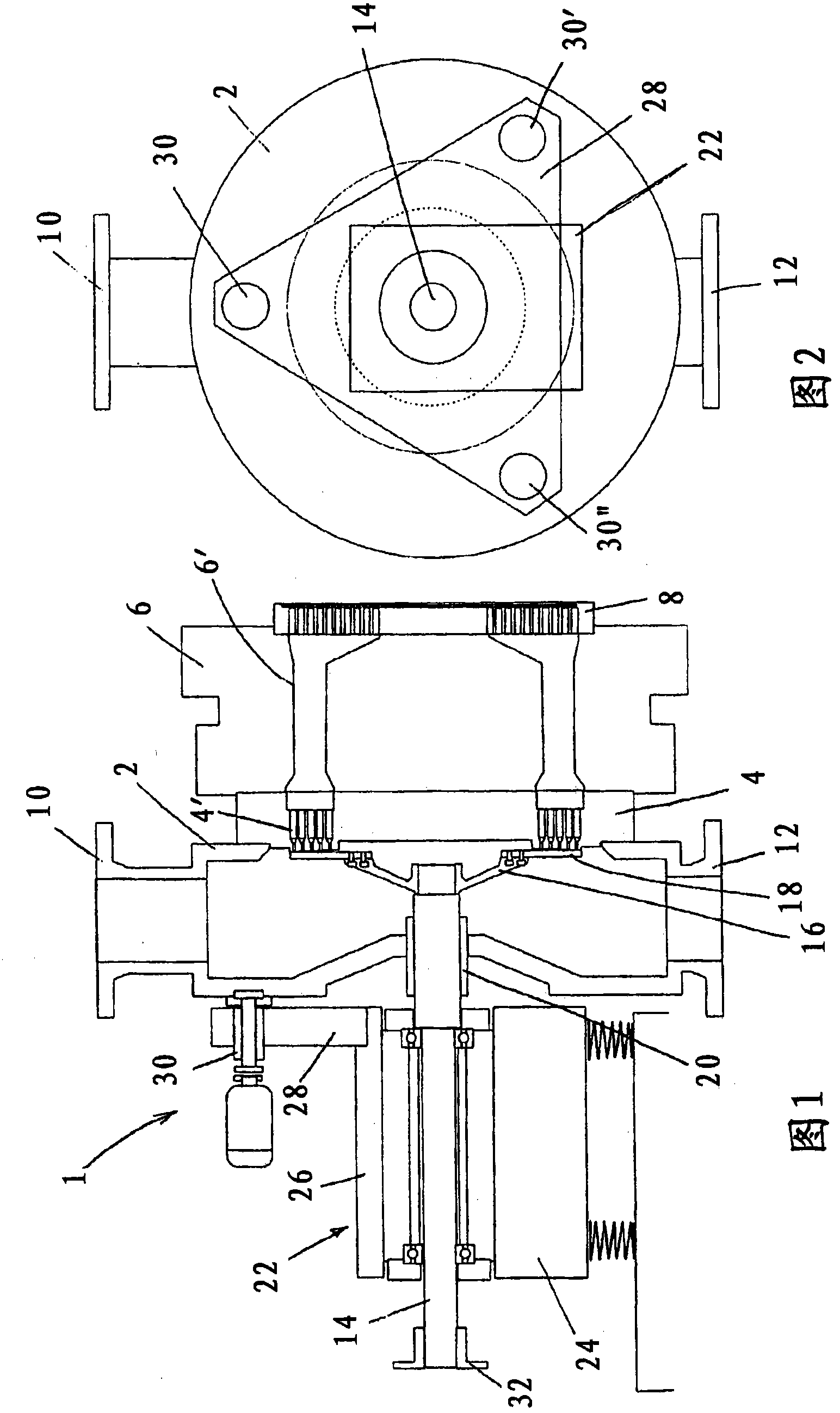

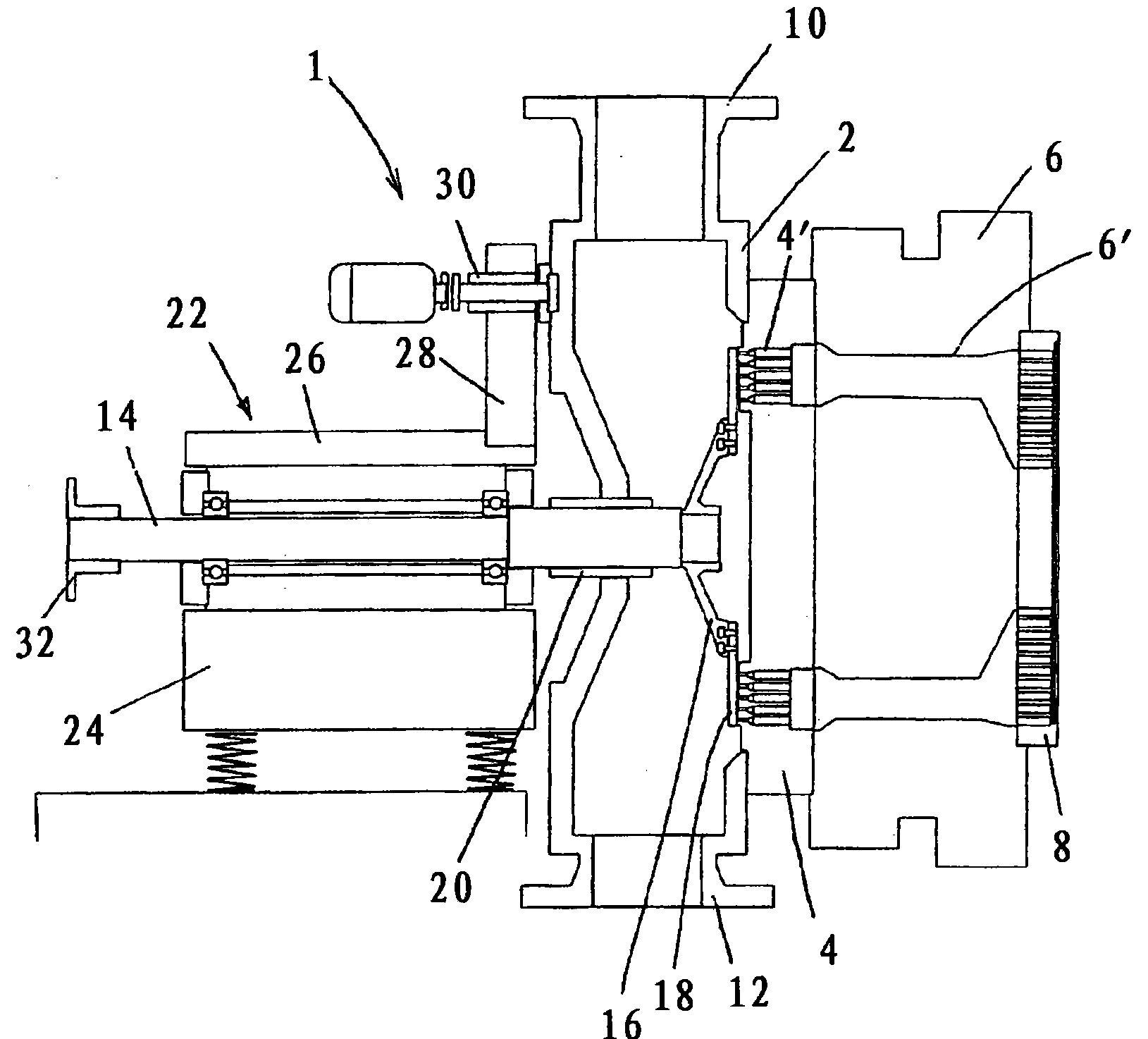

[0043] figure 1 shows a sectional view of an underwater pelletizer with a cutting box 2 in which a tool holder 16 comprising a plurality of knives 18 is rotatably mounted. The knives 18 rotate at a slight to an extremely small distance in front of the blade 4 and the outlet of the plurality of openings 4 ′ provided in the blade. The blade 4 is connected to a nozzle flange 6 of the extruder, not shown. In the nozzle flange 6 a plurality of connecting channels 6 ′ are provided, via which the melt is supplied from the extruder to the respective openings 4 ′ in the blade 4 . Before the melt enters the connecting channels 6', the melt passes through a melt filter 8 in order to remove possible impurities and to avoid clogging of the openings 4'. The cutting box 2 and the blade 4 are fixedly connected to each other, as are the blade 4 and the nozzle flange 6 . The melt discharged in ribbons from the openings 4 ′ is cut off by the rotating knives 18 and forms a granulated product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com