Four-way valve defrosting device

A four-way valve and heat exchanger technology, applied in damage protection, fluid circulation arrangement, refrigeration components, etc., can solve the problems of low defrosting efficiency and poor effect, reduce economic costs, improve system energy efficiency ratio, defrost Quick and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For the convenience of those skilled in the art to understand, the present invention will be described in detail below in conjunction with the accompanying drawings:

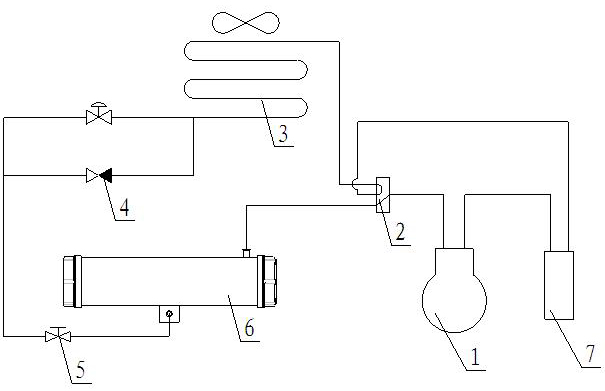

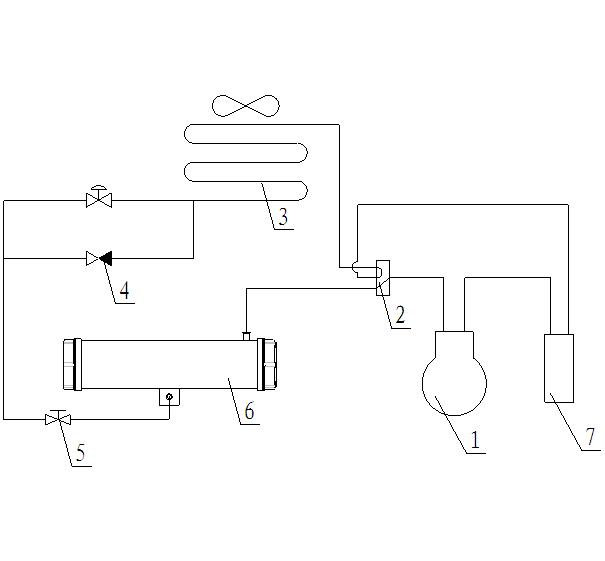

[0017] figure 1 It is a schematic diagram of the four-way valve defrosting device of the present invention, including a compressor 1, a four-way valve 2, an evaporator 3, a one-way valve 4, an angle valve 5, a condenser 6 and a gas-liquid separator 7, and forms a circuit. The evaporator 3 is connected with the compression molding machine 1 through a four-way valve 2 .

[0018] The above-mentioned evaporator 3 of the present invention is a finned evaporator; the condenser 6 is any one of a plate condenser, a shell-and-tube condenser or a casing condenser, and the compressor 1 can be a volume type or a speed type; The valve is a four-way valve commonly used in this field.

[0019] When in use, the refrigerant vapor is charged in the refrigeration cycle system. The connecting circuit is compressor 1, four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com