Manufacture method of a liquid crystal display element, polymer composition and liquid crystal display element

A technology of liquid crystal display elements and manufacturing methods, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems that cannot be ruled out, such as display properties, voltage retention properties, high ultraviolet irradiation, and no reactive mesogens, etc., to achieve Excellent display properties, non-destructive display properties, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0200] 110g (0.50mol) of 2,3,5-tricarboxycyclopentylacetic acid dianhydride as tetracarboxylic dianhydride, 43g (0.40mol) of p-phenylene diamine as diamine and 52g (0.10mol) of 3-(3,5-diaminobenzoyloxy)cholestane was dissolved in 830 g of N-methyl-2-pyrrolidone, and the reaction was carried out at 60°C for 6 hours. The obtained polyamic acid solution was divided in a small amount, and N-methyl-2-pyrrolidone was added to form a solution with a polyamic acid concentration of 10% by weight. The measured solution viscosity was 60 mPa·s.

[0201] Next, 1,900 g of N-methyl-2-pyrrolidone was added to the obtained polyamic acid solution, 40 g of pyridine and 51 g of acetic anhydride were added, and the dehydration ring-closure reaction was performed at 110°C for 4 hours. After the dehydration and ring-closing reaction, the solvent in the system is replaced with a new N-methyl-2-pyrrolidone solvent (in this operation, the pyridine and acetic anhydride used in the dehydration-ring-closing ...

Embodiment 1

[0203]

[0204] In the solution containing polyimide (PI-1) obtained in the above Synthesis Example 1 as the polymer (A), N-methyl-2-pyrrolidone (NMP) and butyl cellosolve (BC ), and then add a compound represented by the following formula (B-1) as the (B) compound, and 20 parts by weight relative to 100 parts by weight of the above-mentioned (A) polymer, to form a solvent composition NMP:BC=50:50 (weight Ratio), a solution with a solid content concentration of 6.0% by weight. This solution was filtered using a filter with a pore size of 1 μm to prepare a polymer composition.

[0205]

[0206]

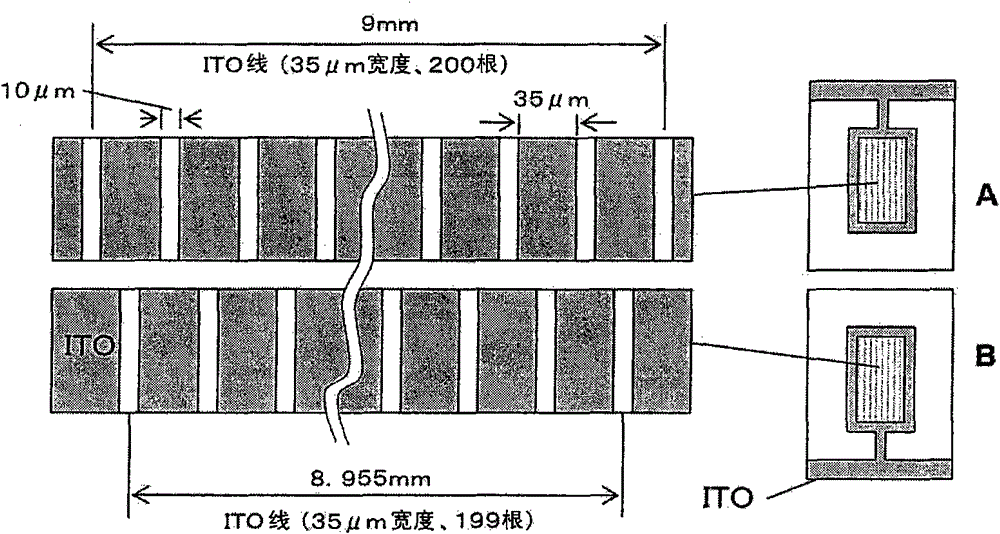

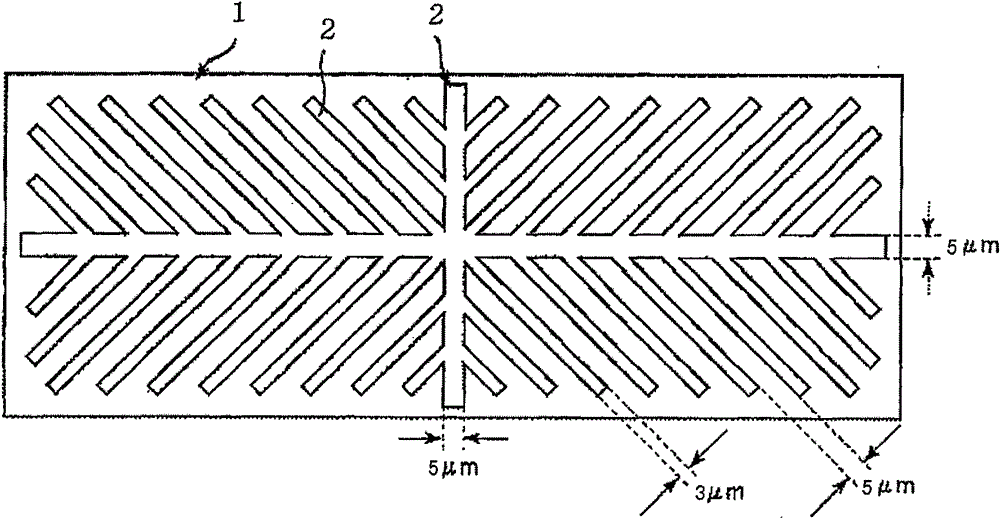

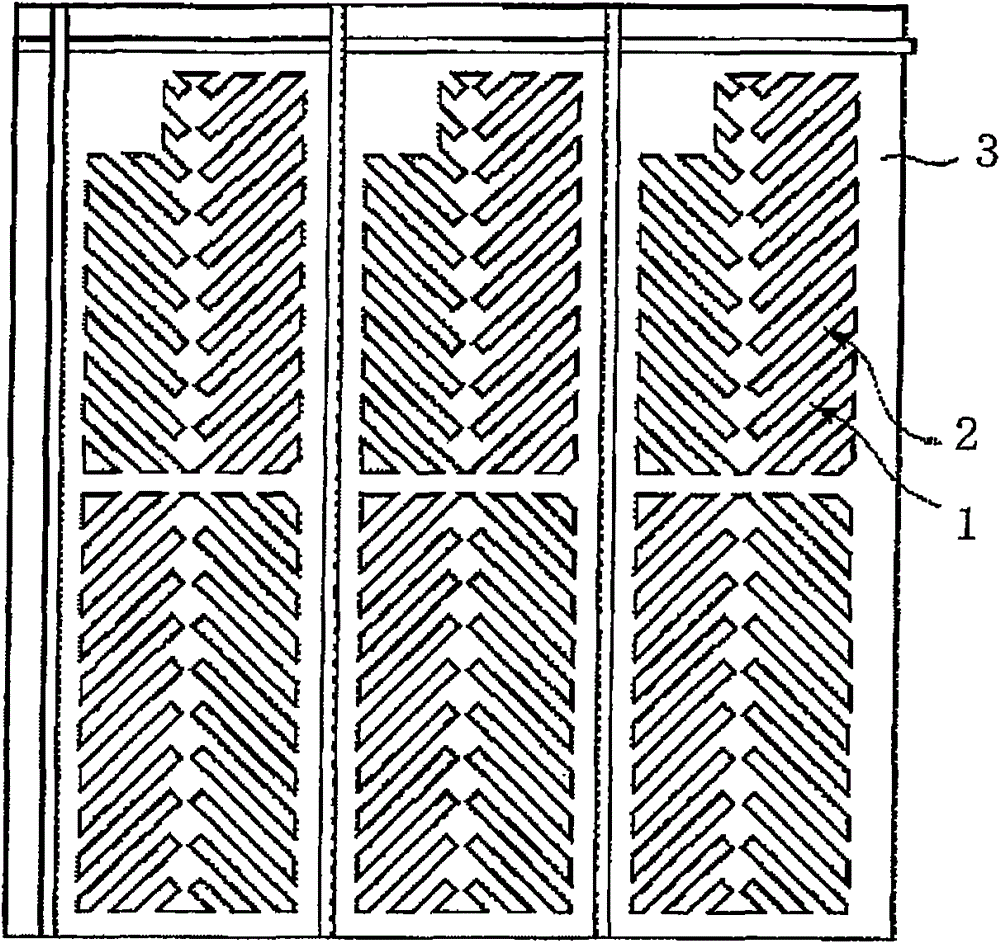

[0207] Using the polymer composition prepared above, the pattern of the transparent electrode (2 types) and the amount of ultraviolet irradiation (3 levels) were changed to produce a total of 6 liquid crystal display elements, which were evaluated as follows.

[0208] [Manufacturing of liquid crystal cell with unpatterned transparent electrode]

[0209] Using a liquid crystal alignment film...

Embodiment 2~5

[0230] Except that in Example 1 above, the type and amount of compound (B) are as described in Table 1, a polymer composition was prepared in the same manner as in Example 1, and various liquid crystal cells were manufactured and evaluated using the polymer composition. .

[0231] The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com