Crown spring cage tyep pin and jack component and jack thereof

A hole assembly and crown spring technology, which is applied to the field of in-line spring type jack pin assemblies, can solve the problems of insufficient insertion force, pin out, unreliable insertion of pins and jacks, etc., so as to improve the reliability of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

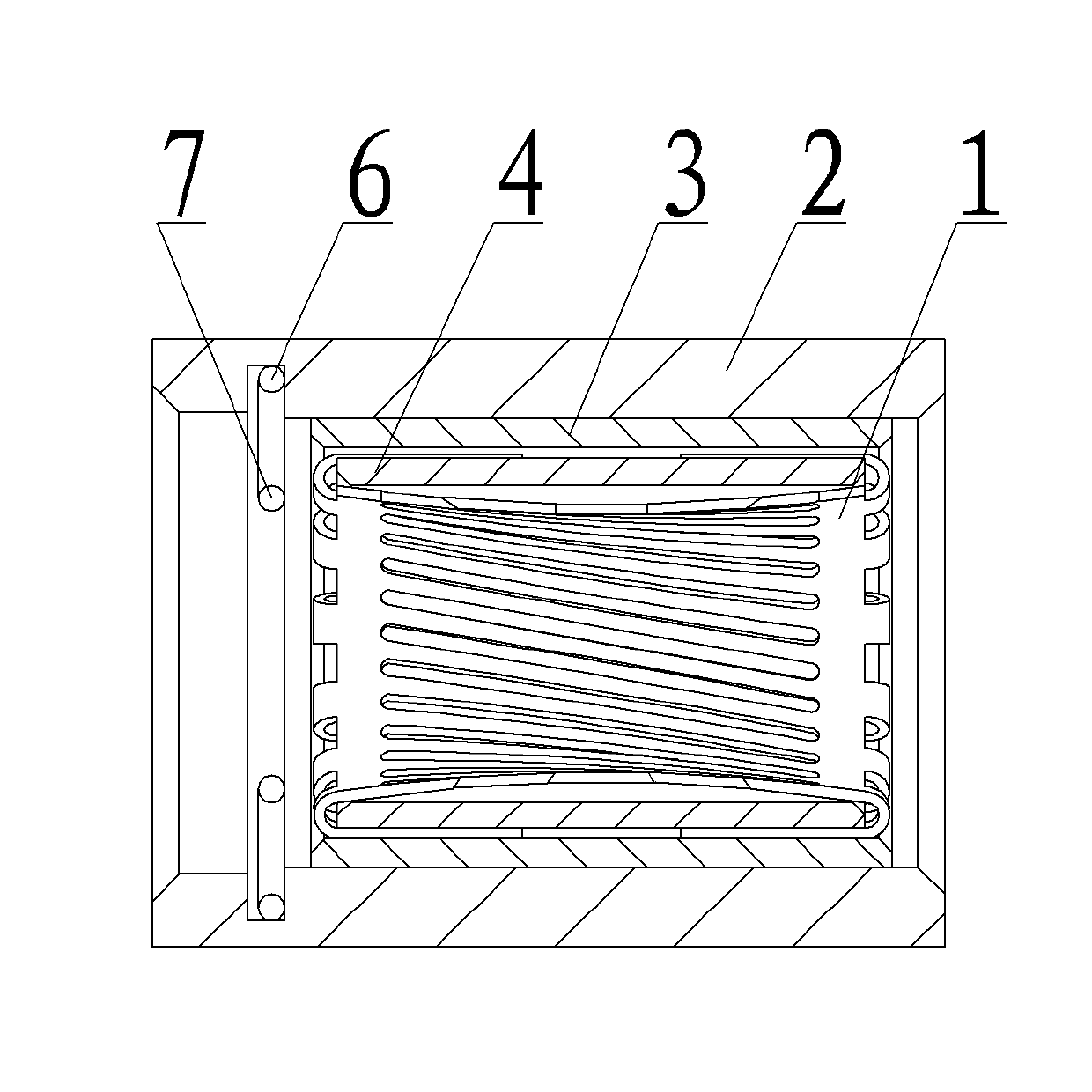

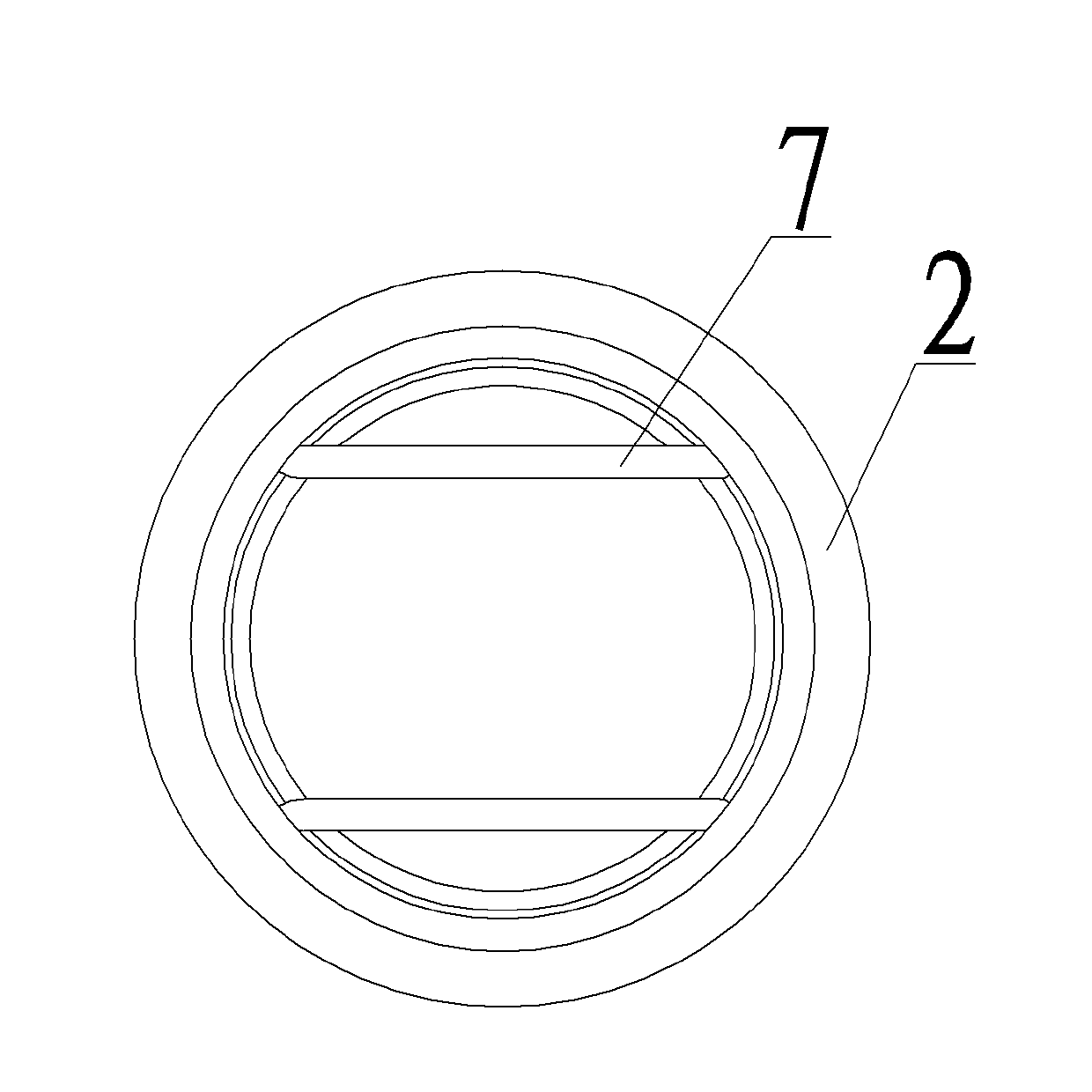

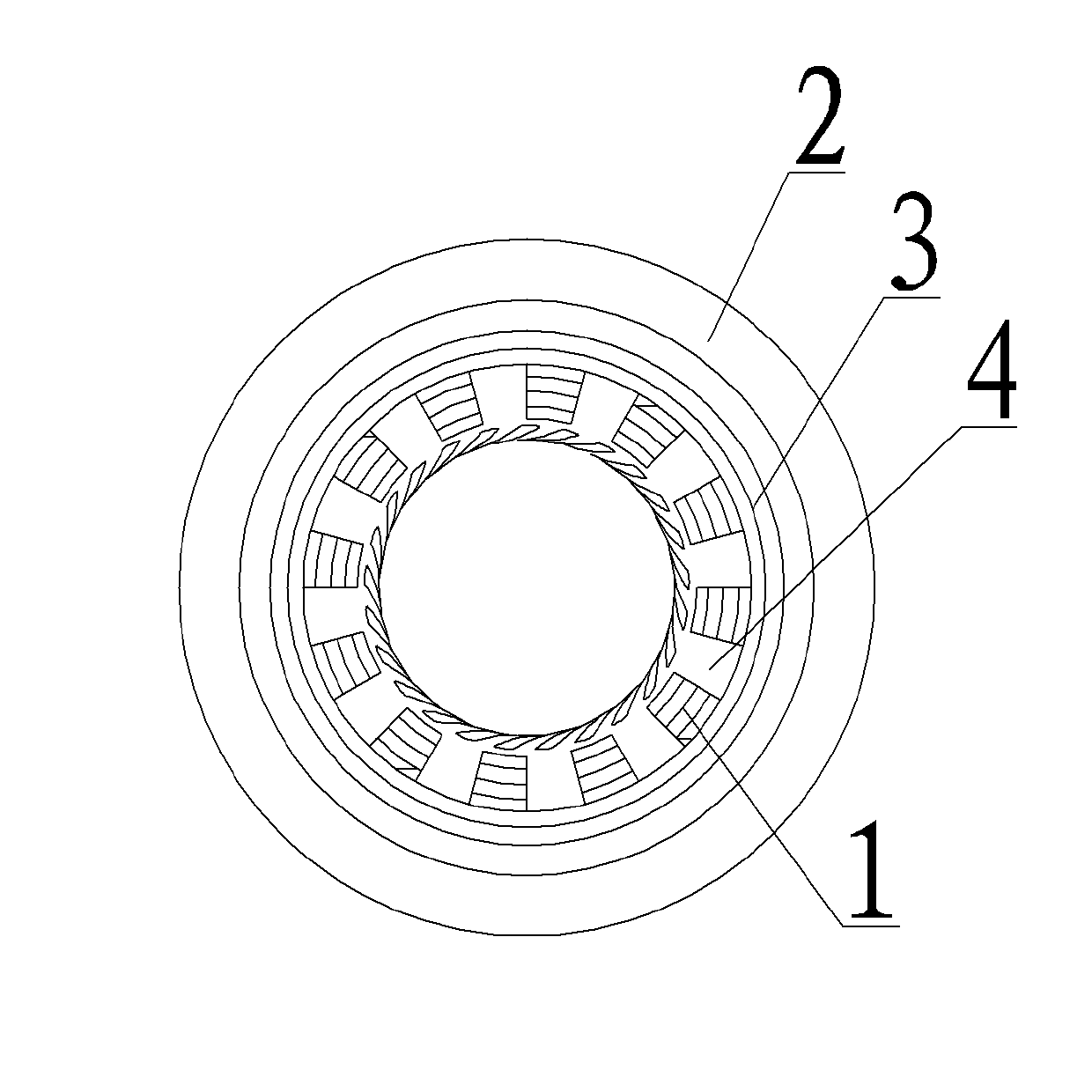

[0026] An embodiment of a crown spring cage pin socket assembly, in Figure 1~7 Among them, the crown spring cage pin jack assembly includes a jack, and a pin 8 is inserted in the jack, and the jack includes an inner sleeve 4, and the outer gap of the inner sleeve 4 is provided with an outer sleeve 3, and the inner sleeve 4 A crown spring 1 is arranged in the inner hole, and the two ends of the crown spring 1 have two end rings 10, and a connecting wire spring bar 11 connecting the two end rings 10 into one is integrally arranged between the two end rings 10, and the two end rings 10 The opposite end face is the inner end face, and the opposite end face is the outer end face. The spaces intersect and are skewed with respect to the axis and form a cage. The outer end faces of both end rings 10 are fixedly connected with outwardly overhanging suspension wire spring bars 12, and the two end rings 10 cooperate with the two ends of the inner hole of the inner sleeve 4, and the sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com