Dustproof gas mask and manufacturing method thereof

A gas mask and manufacturing method technology, applied in respiratory protection devices, fire rescue, life-saving equipment, etc., can solve the problems of complex processing technology and low yield of rubber airbag sealing gaskets, and achieve good sealing performance, good comfort, and simplification. The effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

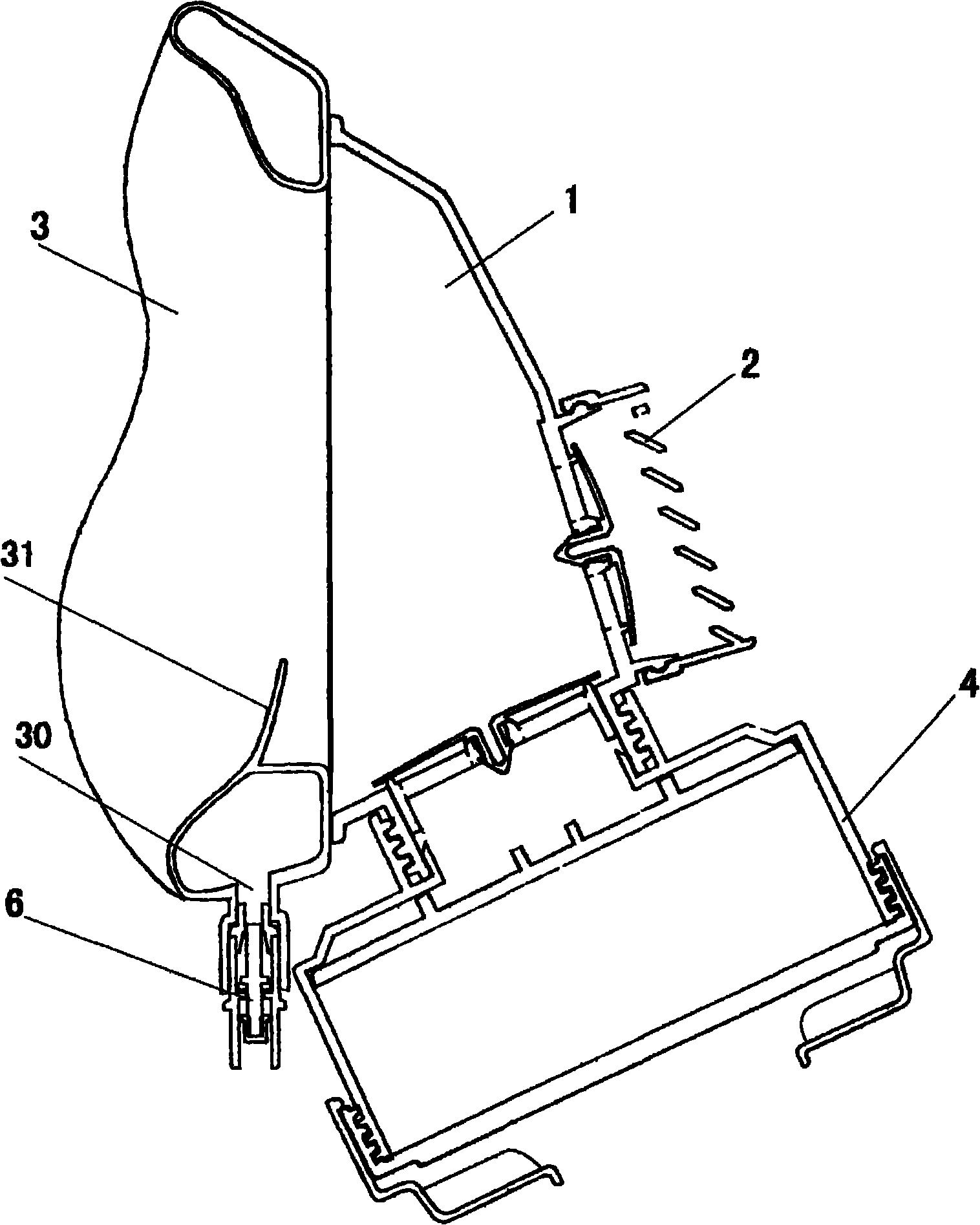

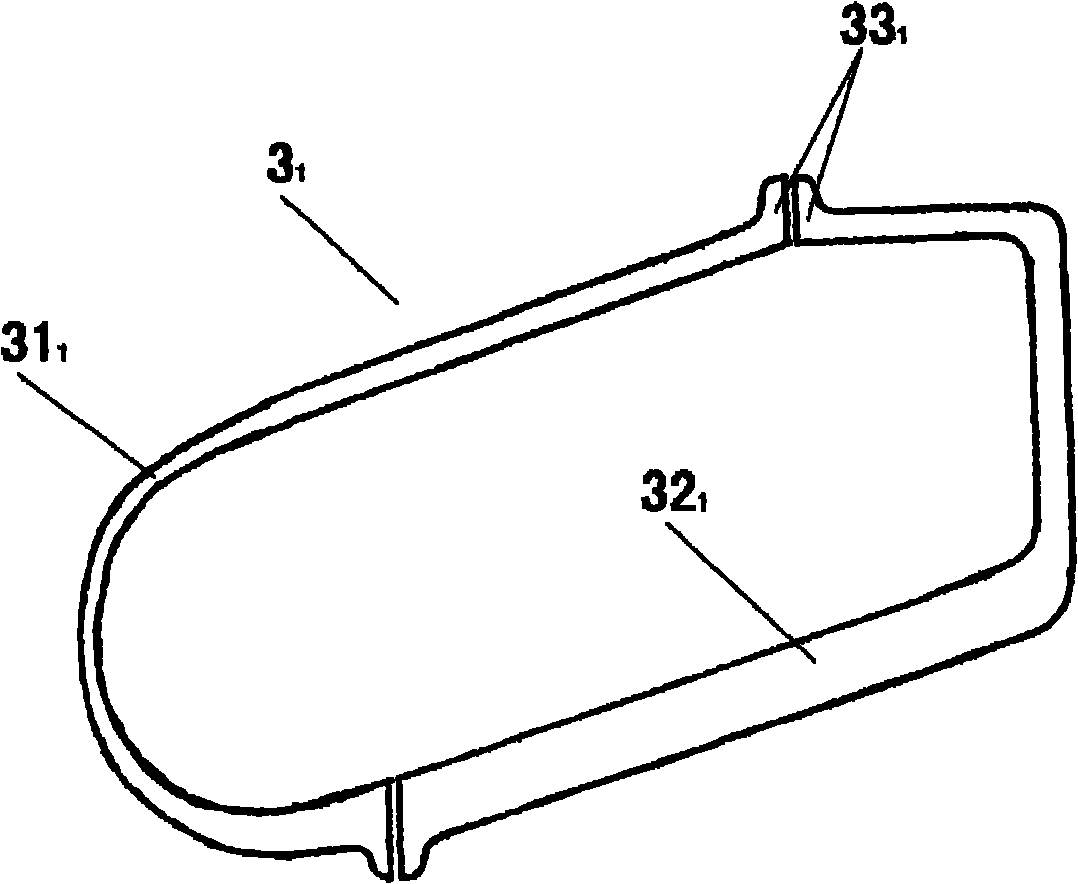

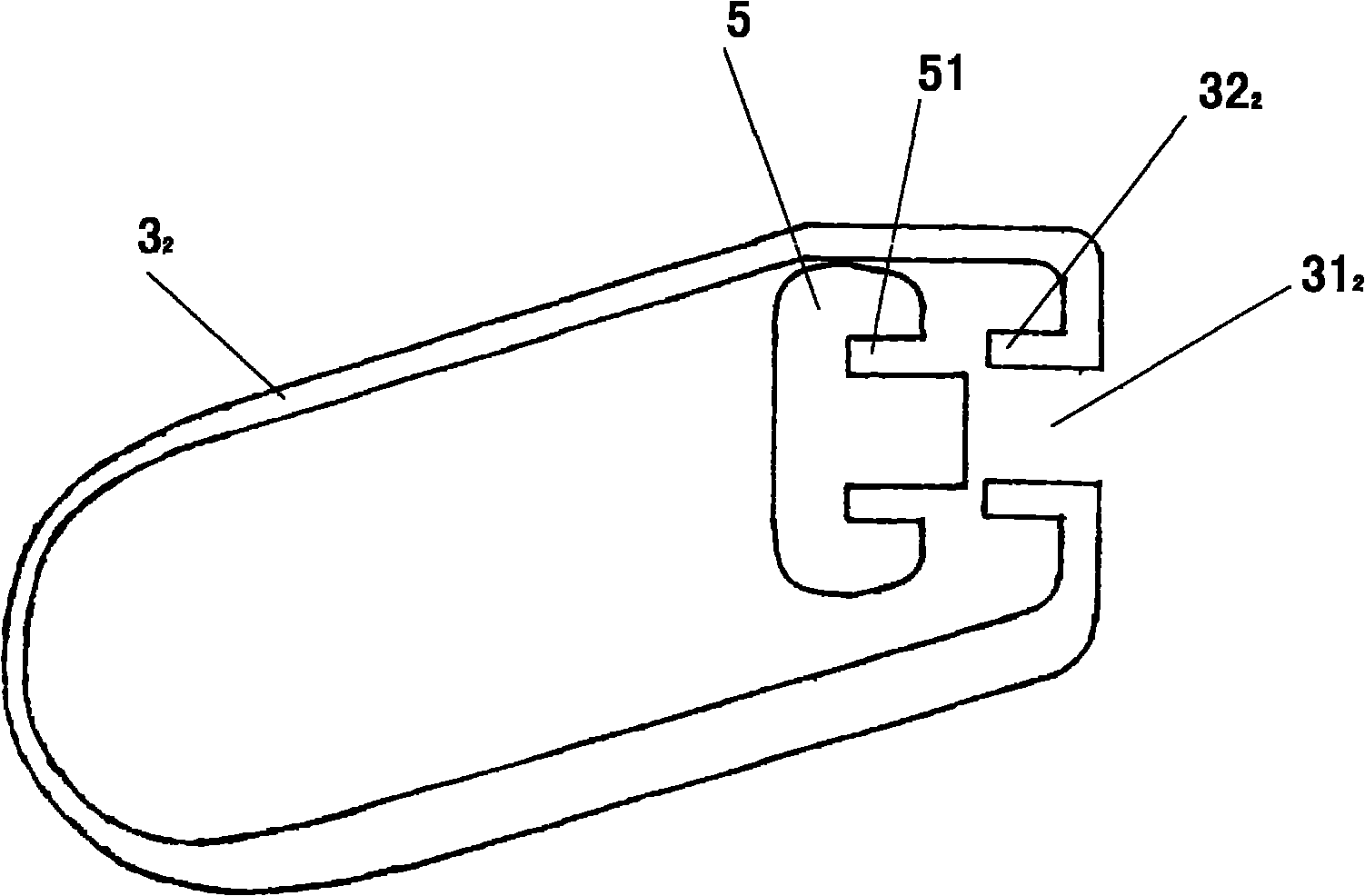

[0019] like figure 1 As shown, a dust-proof gas mask includes a mask main body 1, an exhalation valve cap 2, a sealing gasket 3, and a filter 4. The exhalation valve cap 2 is arranged on the front part of the mask main body 1, and the sealing gasket 3 is an open type The rubber airbag sealing washer 3 formed by bonding the rubber parts, the rubber airbag sealing gasket 3 is arranged on the rear part of the mask main body 1, and the rubber airbag sealing gasket 3 is provided with an air inlet 30, at the air inlet 30 Be provided with air valve 6, be provided with anti-slip sheet 31 at the position that rubber air bag sealing gasket 3 inner side contacts with human body face chin, the wall thickness of rubber air bag sealing gasket 3 and human body face contact position is thinner than other positions; The valve cap 2 is provided with a louver-type air outlet, the direction of the louver-type air outlet is inclined downward, and the thickness of the exhalation valve cap 2 gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com