Tracked carrier special for intertidal belt

A technology of intertidal zone and transport vehicle, which is applied in the field of special crawler transport vehicles in the intertidal zone, which can solve the problems of increased cost, excessively increased control complexity, high cost, etc., and achieves the effect of small grounding specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

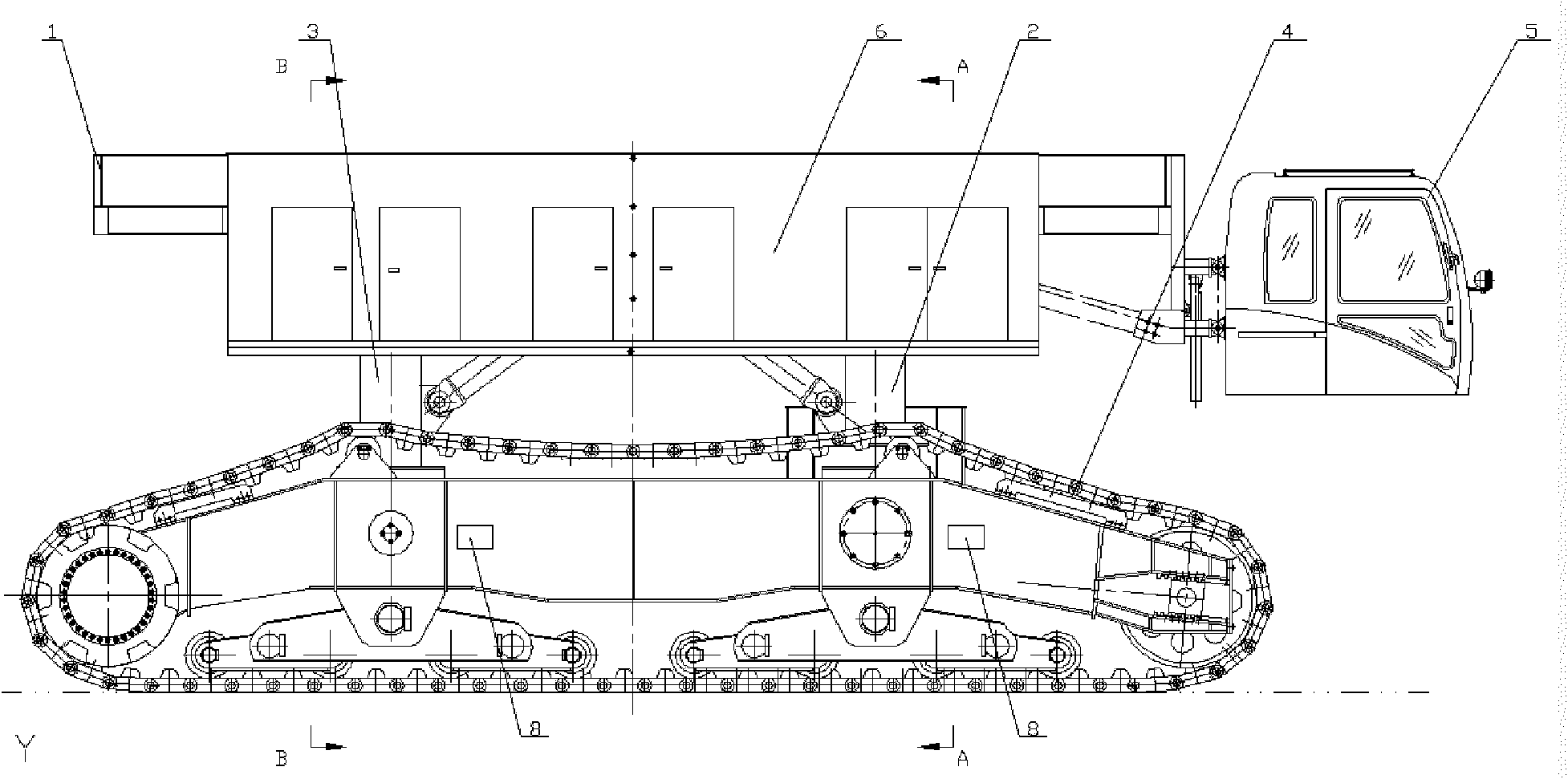

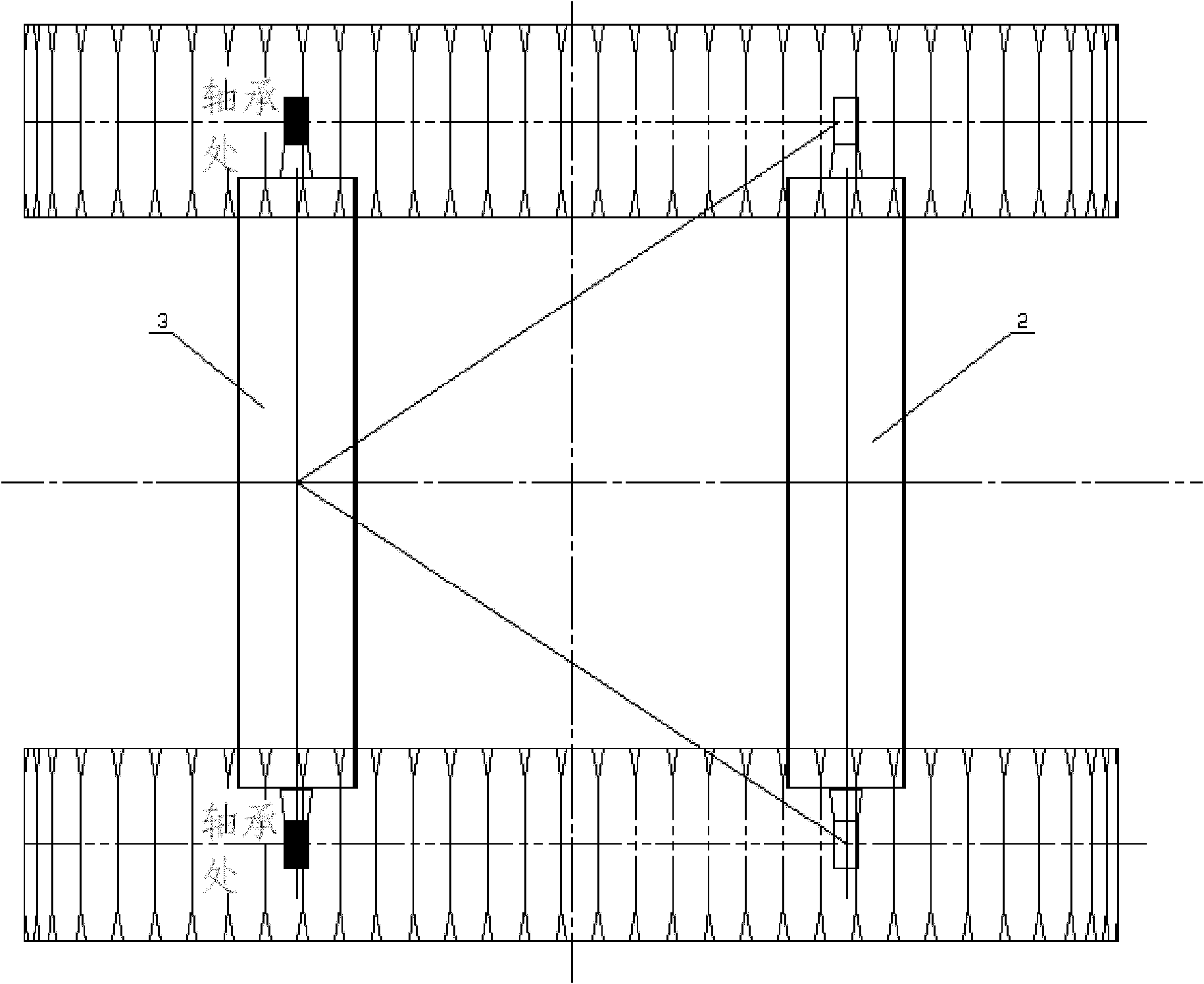

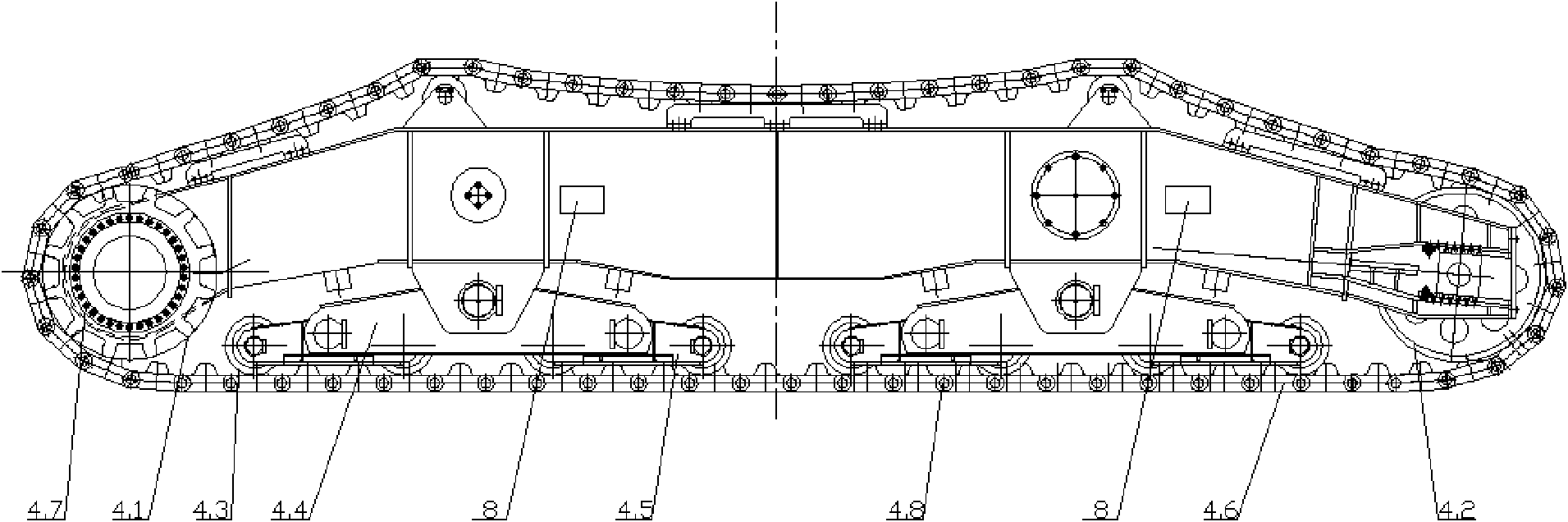

[0025] a kind of like Figure 1 to Figure 7 The special crawler transport vehicle for the intertidal zone shown is composed of a car body 1 , a door-type hingeless connecting beam device 2 , a Y-shaped hinged connecting beam device 3 , a double crawler device 4 , a driver's cab 5 and a power system 6 . Among them, the car body 1 is a load-bearing mechanism, which is composed of main beams, auxiliary beams, planks, and tie bars, and is connected with high-strength bolts. The car body 1 and the double crawler device 4 are connected through the door type hingeless connecting beam device 2 and the Y type hinged connecting beam device 3; the door type hingeless connecting beam device 2 and the Y type hinged connecting beam device 3 are connected with the double track The box-shaped beams I 2.1 and box-shaped beams II 3.1 connected to the device 4 are closed boxes, which can prevent the entry of seawater and have greater buoyancy in the water and reduce the grounding specific pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com