Usage method of stringing construction device for power transmission technology

A technology for construction equipment and overhead transmission lines, which is applied to overhead lines/cable equipment, etc., can solve the problems of increased safety risks in the construction of overhead lines, easy exhaustion of construction personnel, and increased labor intensity of construction personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

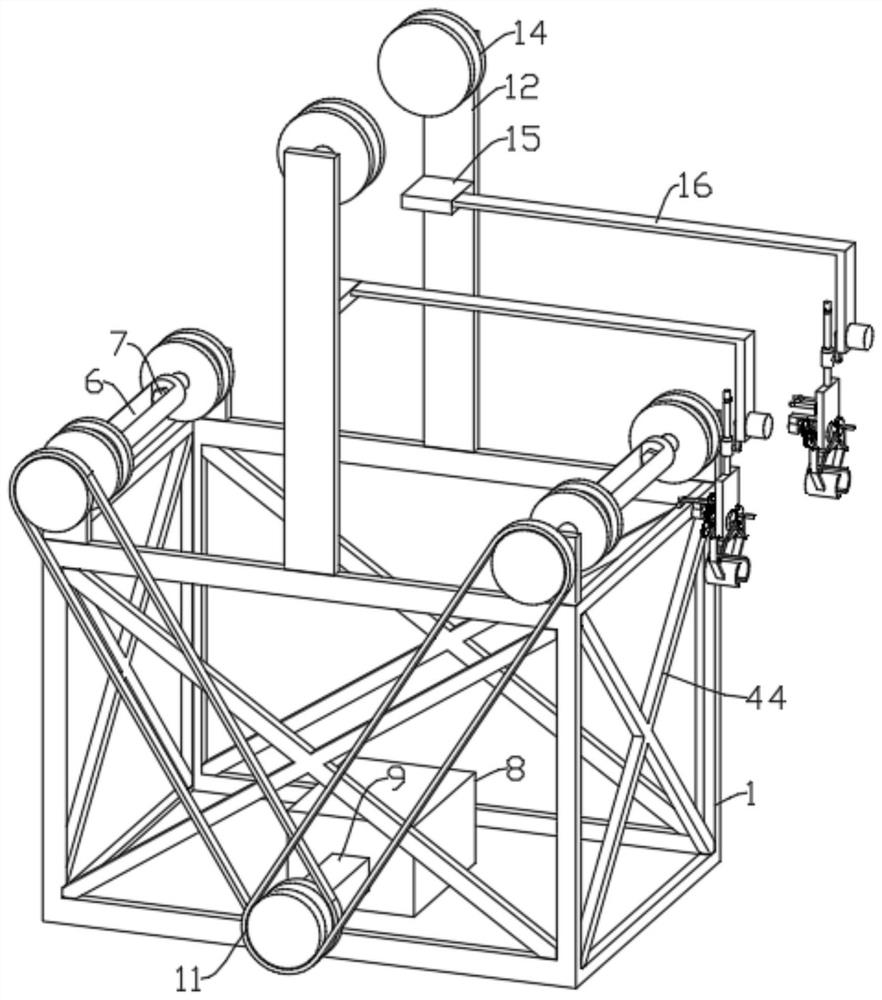

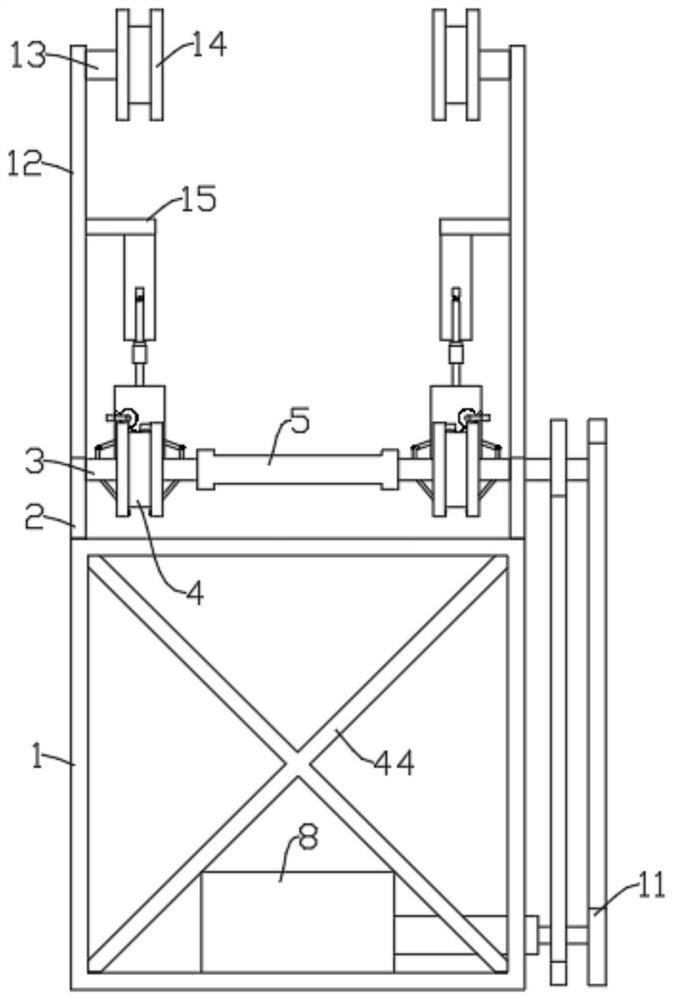

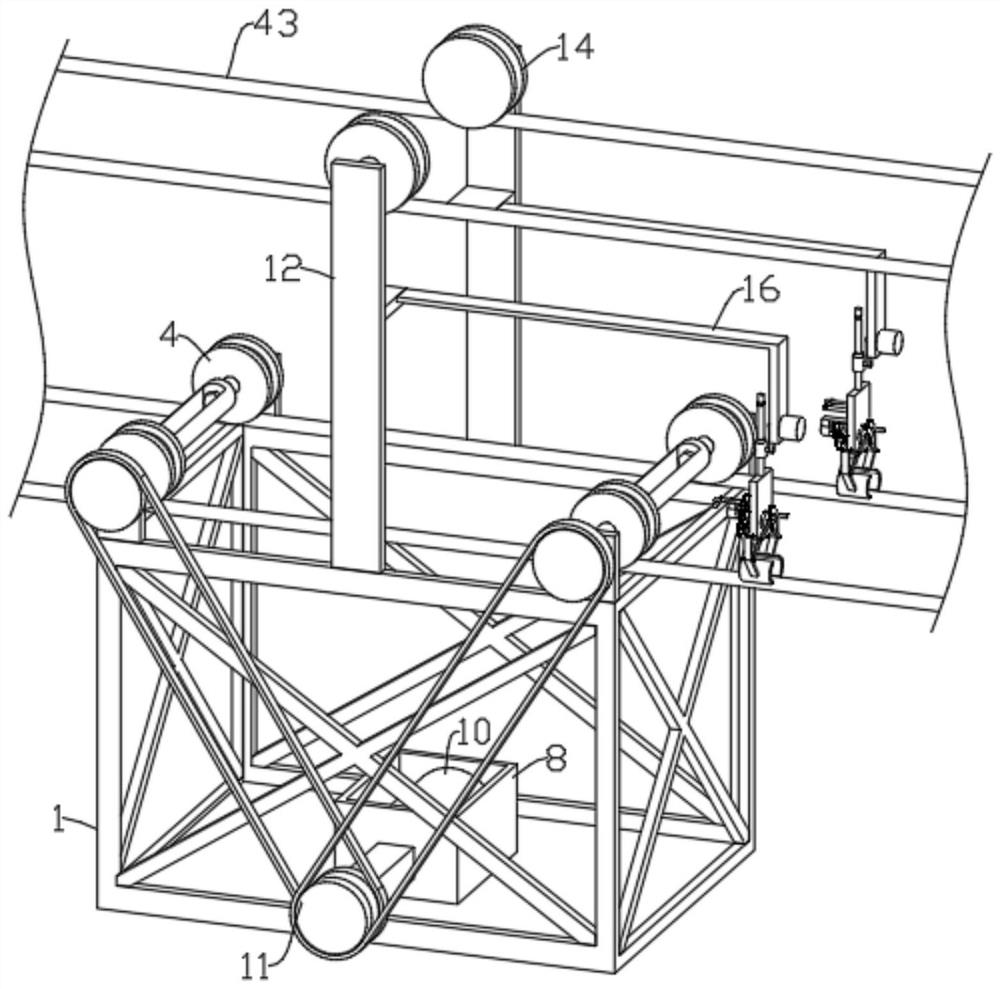

[0036] refer to Figure 1-7 , a method for using wire construction equipment for power transmission technology, comprising the following steps:

[0037] S1: Provide a wire construction auxiliary equipment for power transmission technology. The wire construction auxiliary equipment for power transmission technology includes a housing 1, in which:

[0038] The four corners of the top of the casing 1 are fixedly equipped with side plates 2, and the opposite sides of the side plates 2 can be rotatably installed with driving wheel shafts 3. There is an interval between the two driving wheel shafts 3 on the same side. Both drive wheels 4 are fixedly installed, and a cross bar 5 is provided between the two drive wheel shafts 3 on the same side, and a rectangular opening 6 is provided on the cross bar 5, and bolts 7 are arranged on both sides of the rectangular opening 6, The bolt 7 runs through the cross bar 5 and is threadedly connected to the drive wheel shaft 3. A box body 8 is f...

Embodiment 2

[0046] When the device is used in an environment with high humidity or after rainy weather, since water droplets remain on the wire 43 of the external overhead transmission line, the friction between the driving wheel 4 and the wire 43 in Embodiment 1 is reduced. On the one hand It will affect the driving performance of the device, and on the other hand, it will increase the braking distance of the device.

[0047] refer to Figure 1-7 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that support blocks 15 are fixedly installed on opposite sides of the two vertical plates 12, and a cleaning mechanism is provided on the two support blocks 15, and the cleaning mechanism includes L-shaped support plate 16, one end of the L-shaped support plate 16 is fixedly installed on one side of the support block 15, the lower end of the L-shaped support plate 16 is provided with a carrier plate 17, and the carrier plate 17 is provided with two gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com