Road roller transmission system and road roller

A transmission system and road roller technology, applied in the field of road rollers, can solve the problems of high failure rate, complex internal structure of drive axle of transmission system, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

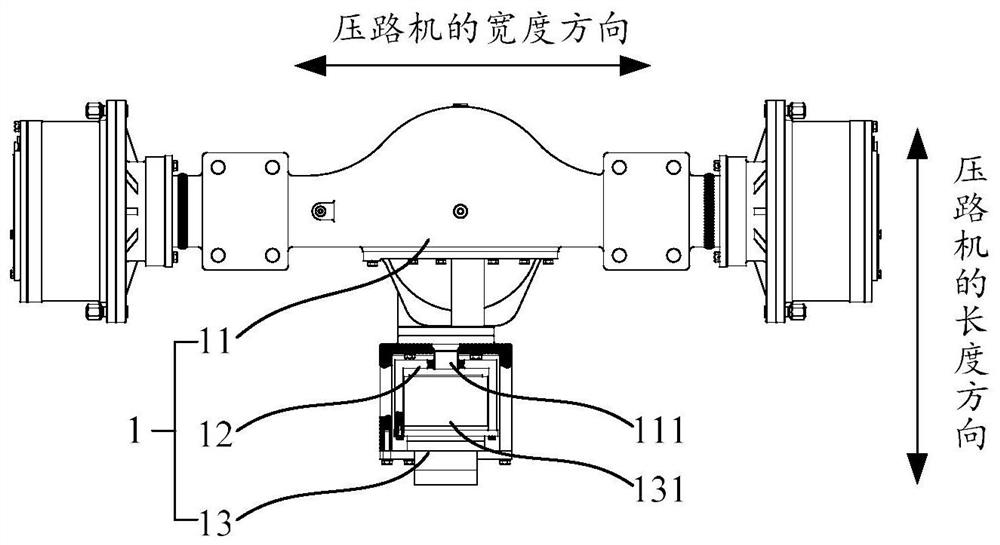

[0045] In this embodiment, a road roller transmission system 1 is provided, which is used for a road roller. like figure 1 As shown, the road roller transmission system 1 includes a driving axle 11 , a connecting mechanism 12 and an integrated speed reducer 13 .

[0046] The driving axle 11 is used to transmit power to the driving wheels of the road roller. The connecting mechanism 12 is located between the drive axle 11 and the integrated speed reducer 13, and the connecting mechanism 12 is connected with the input shaft 111 of the drive axle 11 and the output shaft 131 of the integrated reducer 13, so that the integrated reducer 13 and The drive axle 11 realizes the transmission connection. The input end 132 of the integrated reducer 13 is connected with the hydraulic driving device of the road roller to obtain the output power of the hydraulic driving device. Wherein, the integrated speed reducer 13 integrates the functions of deceleration and braking.

[0047] When the...

Embodiment 2

[0050] This embodiment provides a road roller transmission system 1, which is further improved on the basis of the first embodiment.

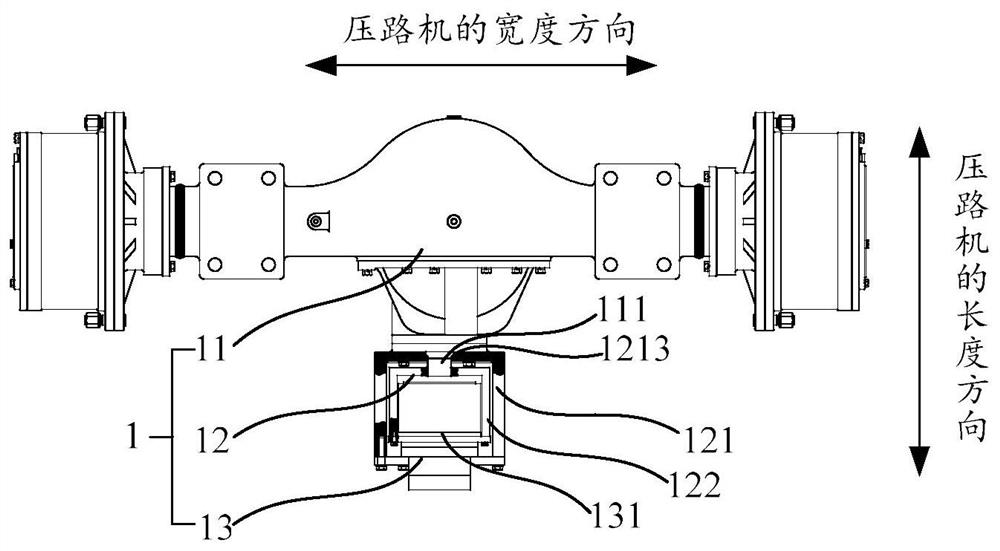

[0051] like figure 2 As shown, the connection mechanism 12 includes a mounting bracket 121 and a transmission flange 122 . The mounting bracket 121 is connected to the driving axle 11 and is located on a side of the driving axle 11 facing the integrated reducer 13 . The first through hole 1213 is arranged on the mounting bracket 121 corresponding to the input shaft 111 of the driving axle 11 , the input shaft 111 of the driving axle 11 passes through the first through hole 1213 and extends into the mounting bracket 121 , and is connected with the transmission flange 122 The end of the transmission flange 122 away from the drive axle 11 is connected to the output shaft 131 of the integrated reducer 13, so that the integrated reducer 13 and the drive axle 11 form a transmission connection, and between the integrated reducer 13 and the drive axl...

Embodiment 3

[0054] This embodiment provides a road roller transmission system 1, which is further improved on the basis of the second embodiment.

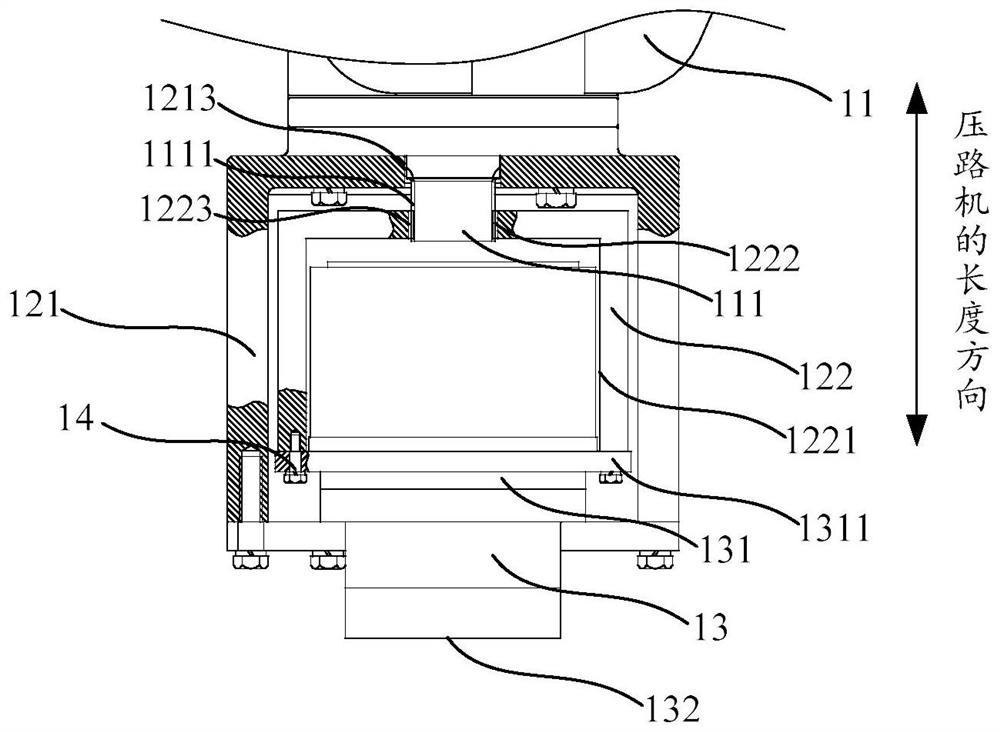

[0055] like figure 2 and image 3 As shown, the transmission flange 122 is provided with a groove 1221 toward the end of the integrated reducer 13, and the groove 1221 is recessed in a direction away from the integrated reducer 13; the output shaft 131 of the integrated reducer 13 extends into the groove 1221 and connected with the transmission flange 122. The shape of the groove 1221 is adapted to the shape of the output shaft 131 of the integrated reducer 13 for easy connection. Wherein, the output shaft 131 of the integrated reducer 13 is detachably connected to the transmission flange 122, which is convenient for disassembly and assembly.

[0056] Further, the output shaft 131 of the integrated reducer 13 is provided with a first stepped portion 1311 protruding in the radial direction. The first stepped portion 1311 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com