Carbon free car

A carbon-free trolley and frame technology, applied in the field of machinery, can solve problems that are not suitable for trolleys without carbon, low cost, inability to accurately adjust the front wheel angle, and inability to adapt to competition venues, etc., to improve energy conversion efficiency and improve The effect of accurate precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

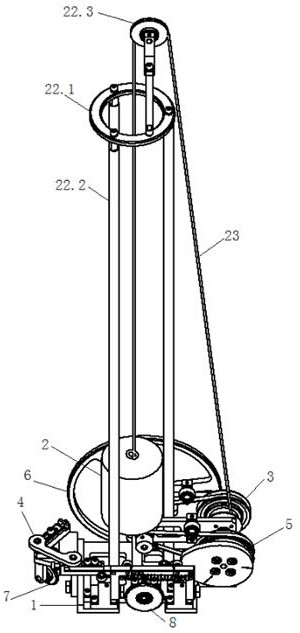

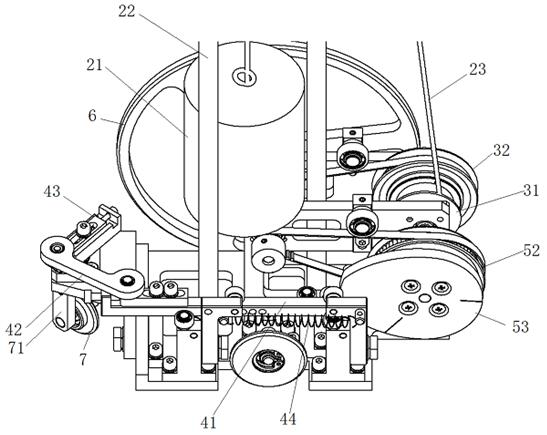

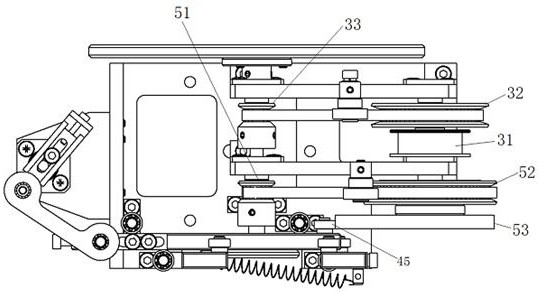

[0033] Combine below Figure 1 to Figure 6 The embodiments of the present invention will be described in detail.

[0034] The carbon-free trolley includes a frame 1, which is characterized in that the frame 1 is equipped with a weight power assembly 2 that converts the gravitational potential energy of the weight into kinetic energy, an active pulley assembly 3, and a weight power assembly 2 connected to it. The crank connecting rod assembly 4, the driven cam assembly 5 connected to the driving pulley assembly 3 and used to push the crank connecting rod assembly 4 to move, the driving wheel 6 connected to the driving pulley assembly 3, and the crank connecting rod assembly 4 The steering wheels 7 and the driven wheels 8 rotatably mounted on the frame 1 are the driving wheels 6, the steering wheels 7 and the driven wheels 8 are distributed in a triangle shape, and respectively contact the ground to prop up the frame 1 horizontally, The steering wheel 7 is located in front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com