Elevator operation control system and method thereof

A technology for elevator operation and control system, which can be used in transportation and packaging, elevators, etc., and can solve problems such as problems with operation control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

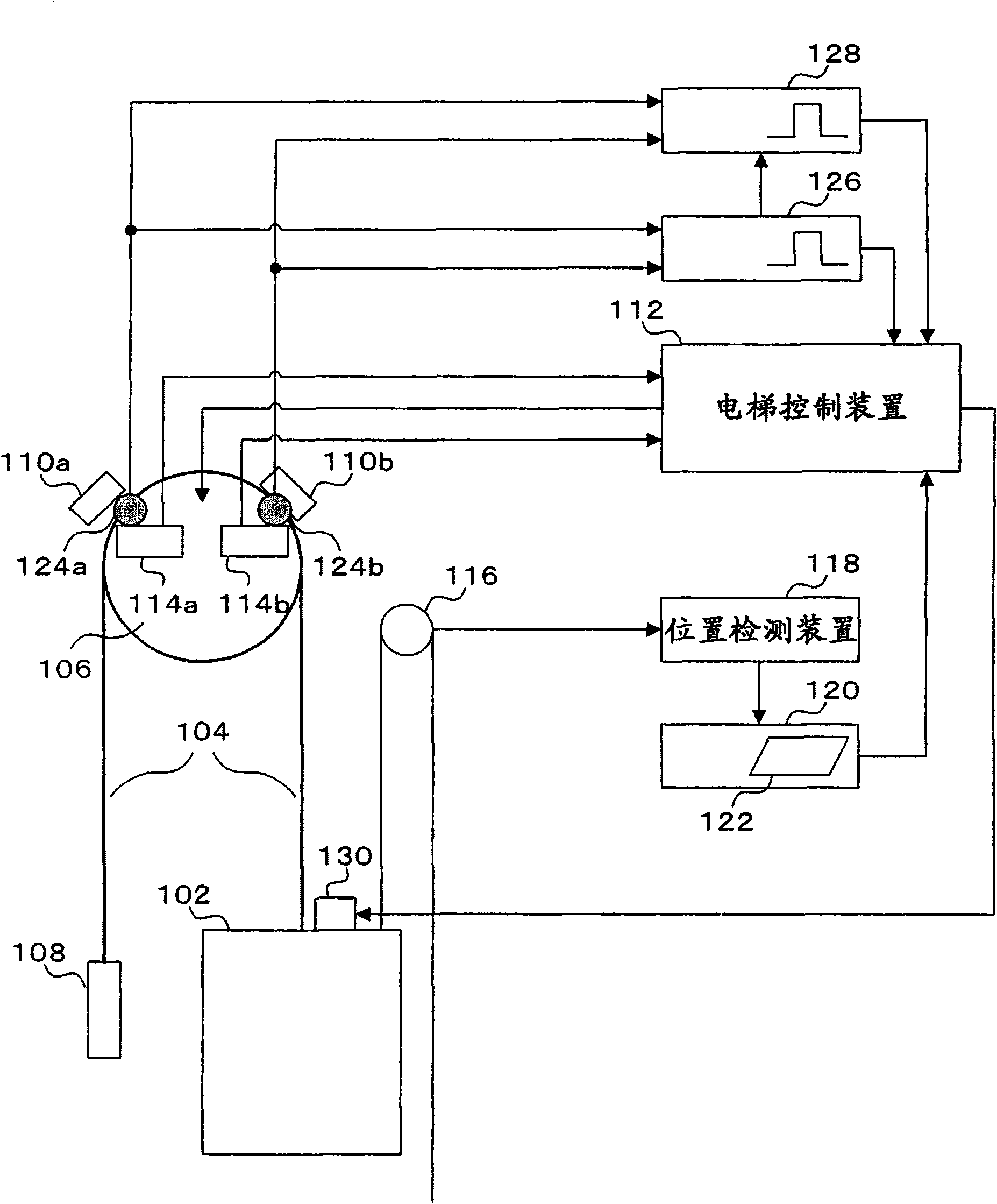

[0023] Hereinafter, an embodiment as an example of the present invention will be described with appropriate reference to the drawings. figure 1 An example of the schematic configuration of the entire elevator operation control system in the embodiment of the present invention is shown. The car 102 is accommodated in a car frame not shown in the figure, and the car frame installed at one end of the main cable 104 travels in the hoistway (not shown) by the traction machine 106. The traction machine 106 has a The motor of the power source for elevator travel and the sheave on which the main rope is wound. A balance weight 108 is suspended from the other end of the main cable. The motor of the hoisting machine 106 and the brakes 110a and 110b for braking the rotation of the hoisting machine 106 are controlled by the elevator control device 112, and the car 102 is driven to stop at the arrival floor. From the viewpoint of the safety of elevator operation, a plurality of brakes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com