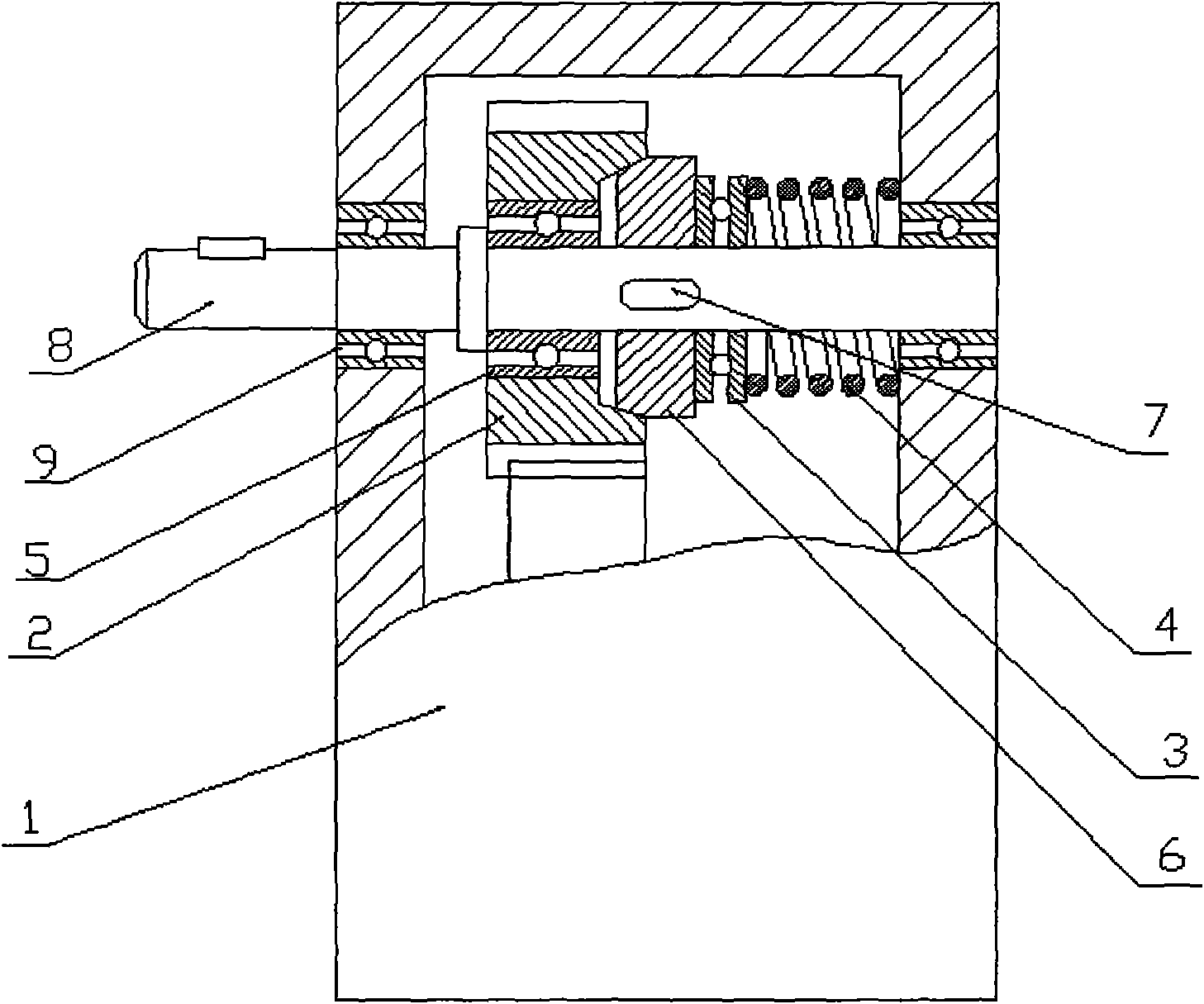

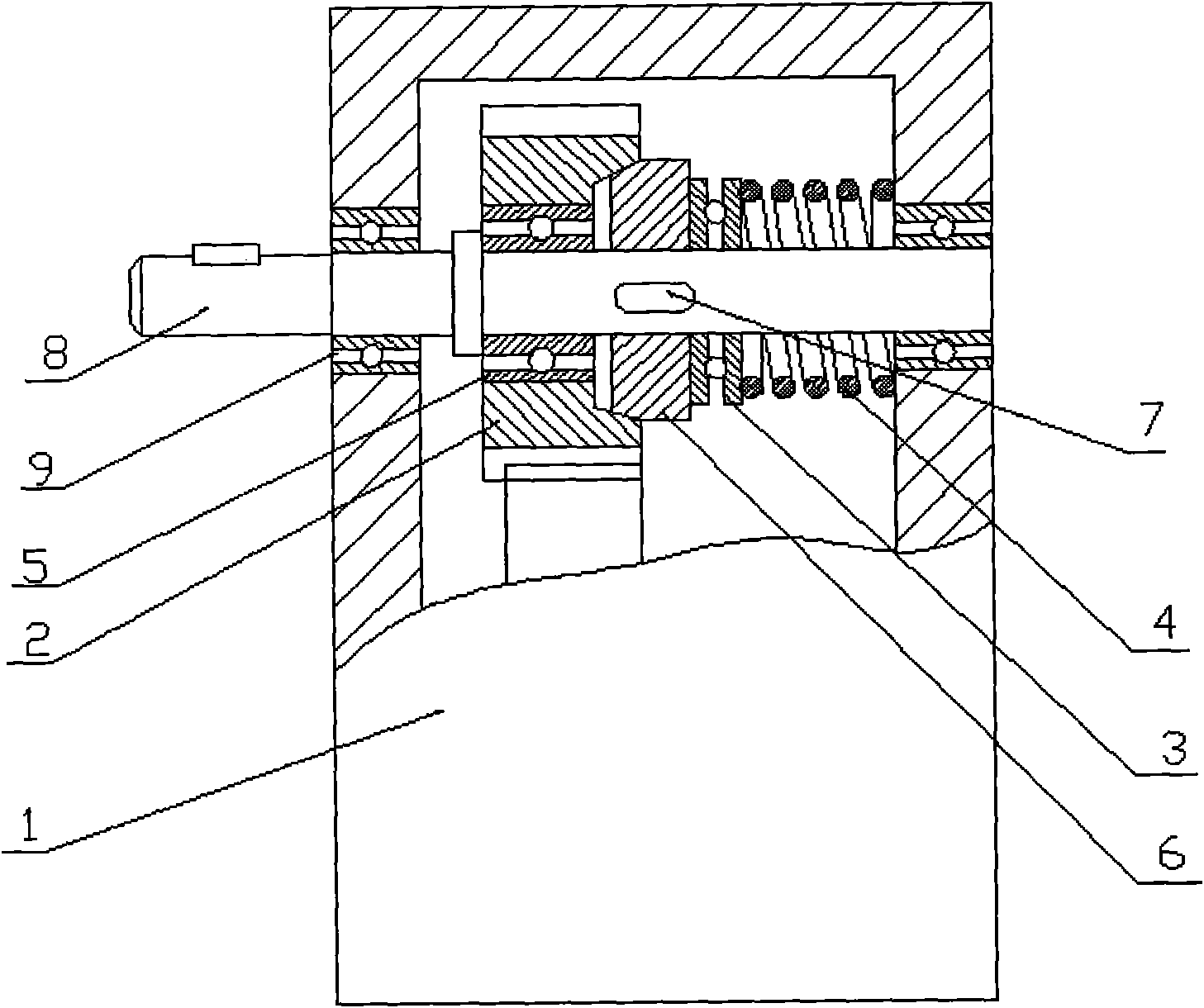

Novel speed reducer with torsion limitation function

A torque-limiting and reducer technology, applied to clutches, automatic clutches, components with teeth, etc., can solve problems such as damage to mechanical equipment parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The final stage gear (2) is installed on the output shaft inside the gearbox (1) through the ordinary bearing (5). ) is installed on the output shaft (8) on the side of the final gear (2). When installing, it must be ensured that the friction disc (6) has the freedom to slide along the axial direction of the output shaft (8) without contact with the output shaft (8) For the degree of freedom of relative rotation, on the side corresponding to the final gear (2) and the friction disc (6), an inner tapered surface with the same taper as the end face of the friction disc (6) is produced, and the two plane bearings (3) are installed at the same time On the top of the output shaft (8), put one of them against the left side of the friction disc (6), and the other one against the inner right side of the gearbox (1) case, A spring (4) is installed on the output shaft (8) between the plane bearings (3), and the spring (4) passes through one of the plane bearings, and the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com