Products production process capability analyzing system and method

A production process capability and production process technology, applied in the field of communications, can solve the problems of low efficiency and high requirements for testers, and achieve the effect of improving work efficiency and simplifying manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiment of the present invention provides a product production process capability analysis system and method, which can simplify user operations and improve analysis efficiency.

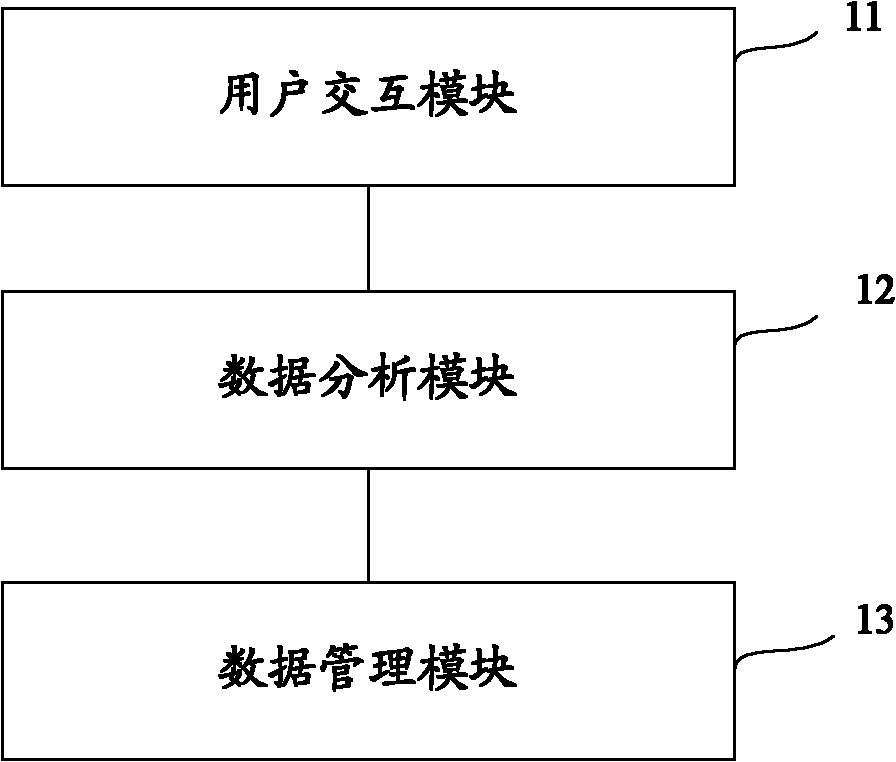

[0018] The embodiment of the present invention provides a product production process capability analysis system, such as figure 1 shown, including:

[0019] The user interaction module 11 is used to receive the test index information and test instructions submitted by the user, provide the test index information and test instructions to the data analysis module, and receive the test results returned by the data analysis module;

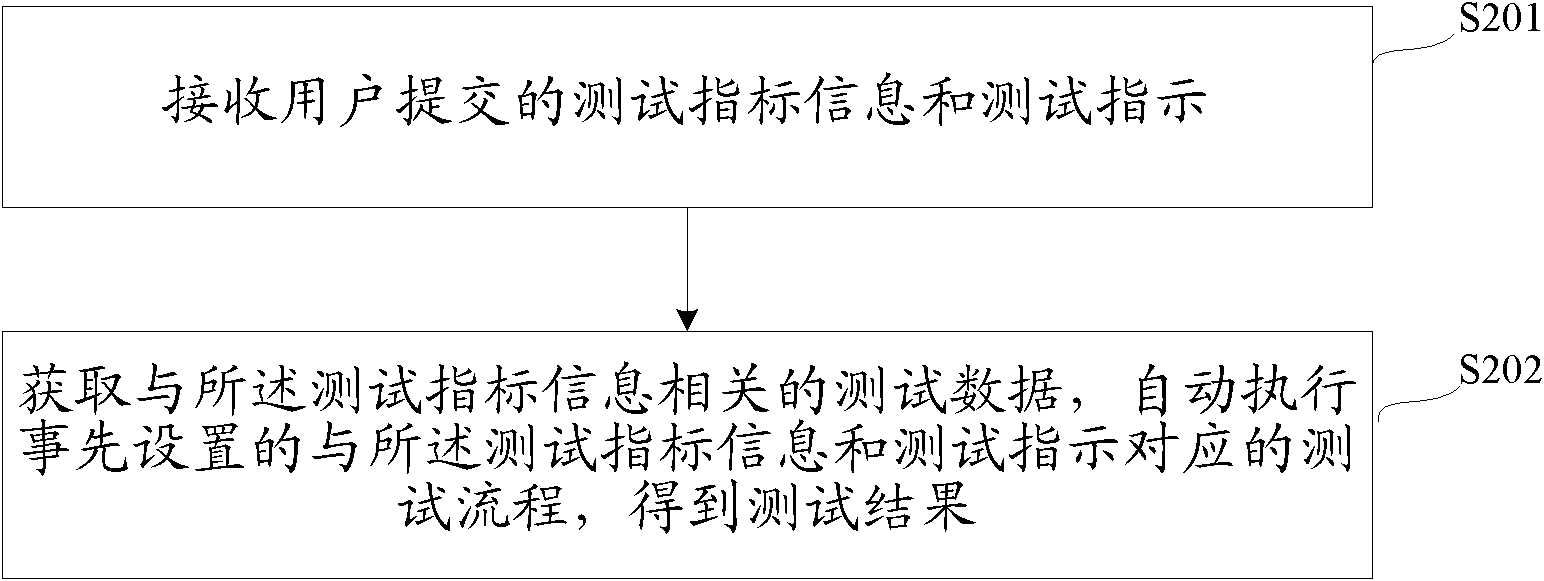

[0020] The data analysis module 12 is used to obtain test data related to the test index information from the data management module, automatically execute the test process corresponding to the test index information and test instructions set in advance, and provide the obtained test results Interaction module for users;

[0021] The data management module 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com