Transverse l-shaped alternate anti-oscillation hardware

An in-line, anti-dance technology, applied in the field of overhead transmission lines, can solve problems such as hidden dangers in construction safety, blind spots in adjustment, breakdown and flashover, etc., to achieve convenient installation and operation, solve the problem of ball head falling out, and good voltage equalization characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

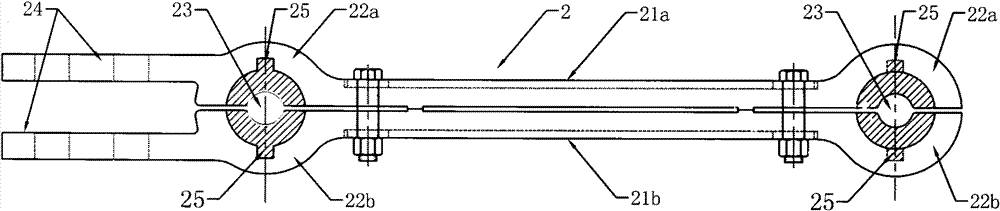

[0026] The anti-flying fitting of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 8 As shown, the anti-galling fitting in this example is explained by taking two split sub-conductors as an example. The inline interphase anti-galling fitting includes a composite insulator 1 and two sub-conductor spacers 2. One end of the composite insulator 1 is connected by a ZBD type hanging The plate 3 is hinged with a sub-conductor spacer 2, and the other end of the composite insulator 1 is hinged with a sub-conductor spacer 2 through a right-angled hanging plate 4, and a turnbuckle screw is connected between the right-angled hanging plate 4 and the sub-conductor spacer 2 5. The turnbuckle 5 at the end of one screw 52 is hinged with the right-angle hanging plate 4 , and the ear handle II54 at the end of the other screw 52 is hinged with the sub-conductor spacer 2 .

[0028] Such as figure 1 , figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com