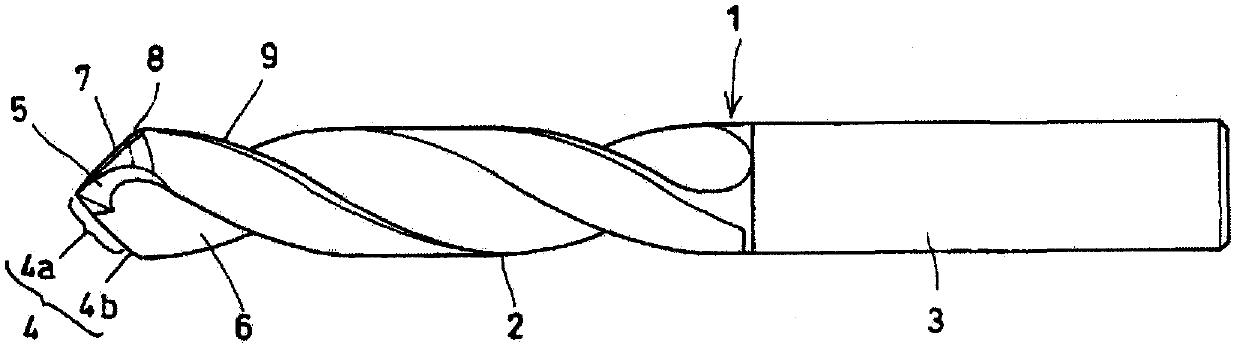

Twist drill bit

A technology of twist drill and drill point angle, which is used in twist drills, repair drills, drilling tool accessories, etc., can solve problems such as tremor and long time, and achieve high-quality drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

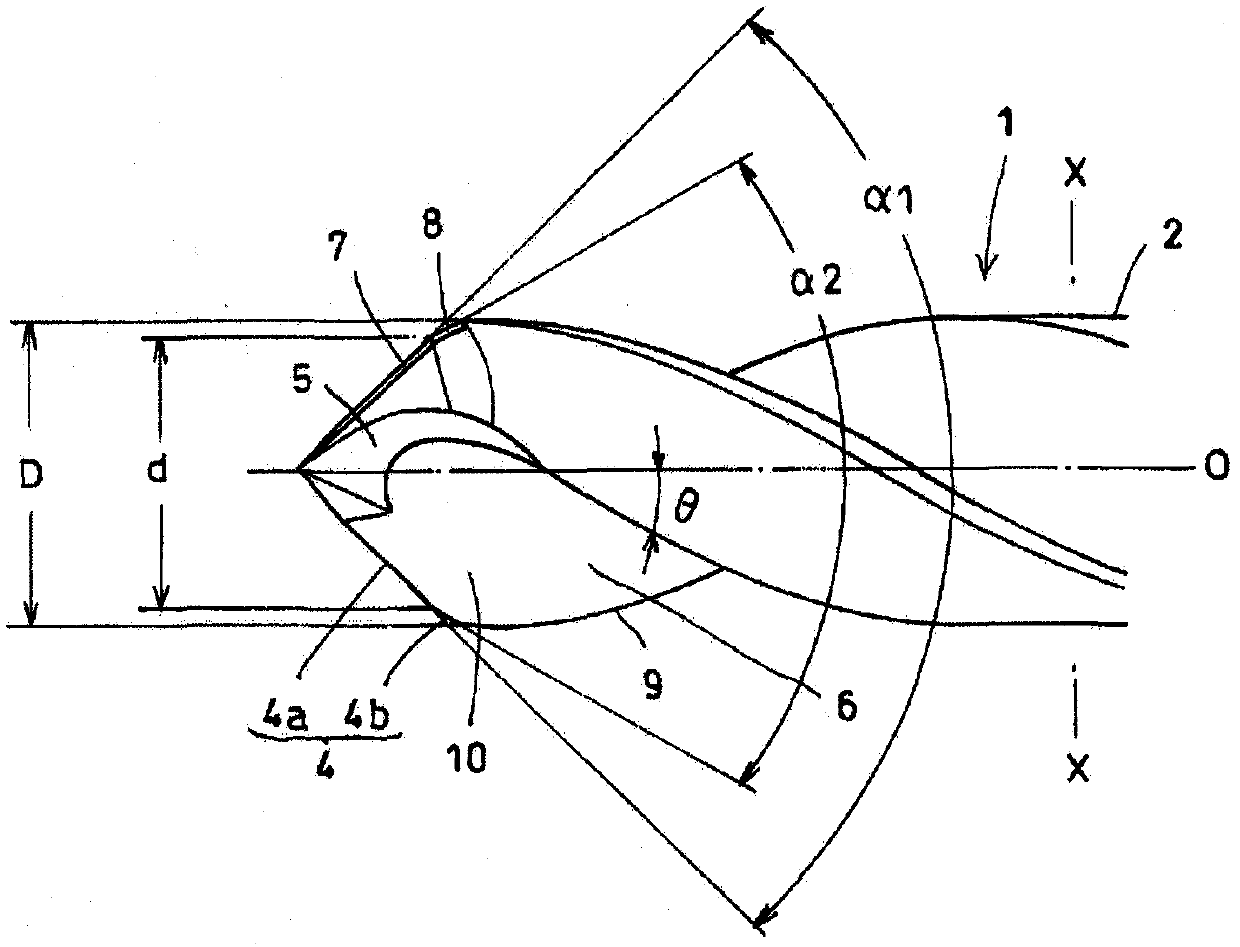

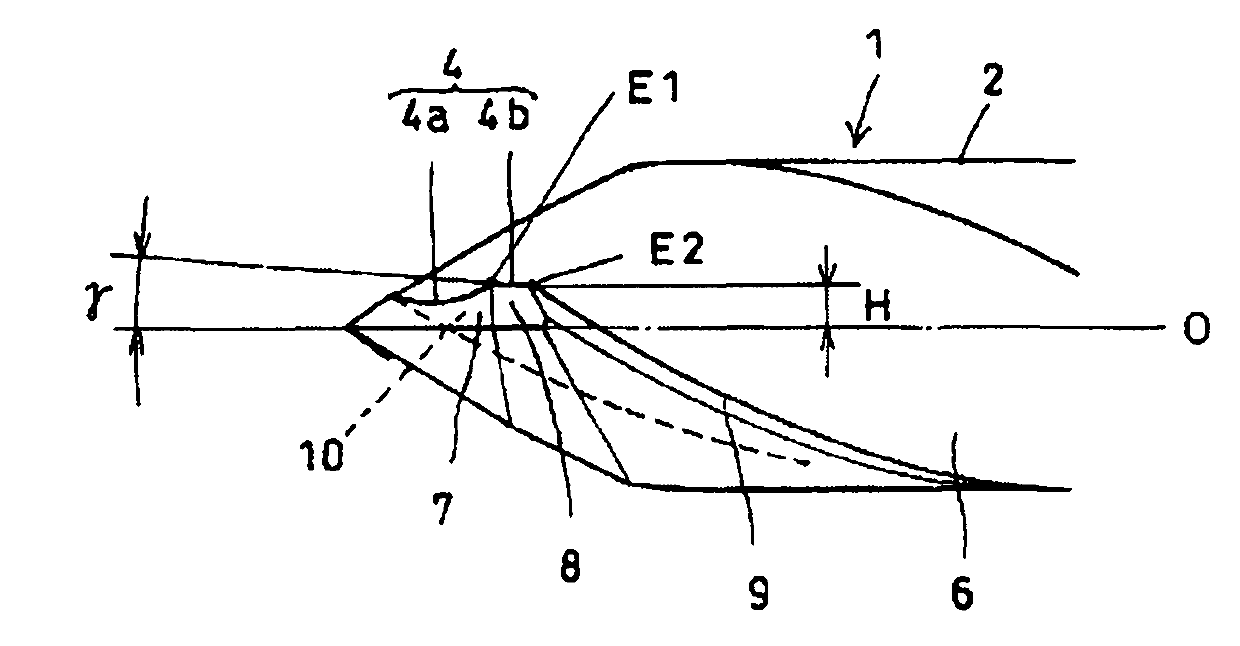

[0043] The influence of the inclination angle γ of the secondary cutting edge relative to the rotation axis on the drilling quality in double-angle drills was studied. The specifications of the drill used in the test are as follows: Drill diameter D = Φ10 mm, the drill point angle of the main cutting edge is 120°, the drill point angle of the secondary cutting edge is 60°, and the diameter of the outer end of the main cutting edge d = 0.9 D, and the inclination angle γ of the minor cutting edge was changed as shown in Table 1.

[0044] The workpiece uses a 3mm thick CFRP plate. Cutting conditions were: cutting speed Vc=100 m / min, and feed speed f=0.05 mm / rev. Table 1 lists the experimental results.

[0045] In the row indicating tremor in Table 1, "+" indicates "no tremor occurred", "±" indicates "slight tremor occurred", and "-" indicates "tremor occurred". In the row indicating fuzzing, "+" means "no fuzzing occurs and the quality of the inner surface of the drilled hole ...

example 2

[0050] Next, the influence of the different drill point angle α2 of the secondary cutting edge of the double-angle drill on the drilling quality and top wear is studied. The specifications of the drill used in the test are as follows: drill diameter D = Φ6 mm, drill point angle α1 = 140° of the main cutting edge, and drill diameter d = 0.83D at the outer end of the main cutting edge.

[0051] The workpiece uses a 10mm thick CFRP plate. Cutting conditions were: cutting speed Vc=100 m / min, and feed speed f=0.05 mm / rev. Table 2 lists the experimental results.

[0052] In the row indicating fuzzing of Table 2, "+" means "no fuzzing occurs and the quality of the inner surface of the borehole is excellent", and "-" means "fuzzing occurs and the quality of the inner surface of the borehole is poor". Top wear was evaluated after 500 holes were drilled. The crown wear amount in the evaluation cell represents the maximum flank wear amount (mm).

[0053] [Table 2]

[0054]

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com