Power tool, especially hand-held power tool

A hand-held machine tool and machine tool technology, which is applied in the direction of manufacturing tools, metal processing equipment, sawing machine devices, etc., can solve the problems of complex structure, inability to change support characteristics, etc., and achieve the effect of avoiding forced coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

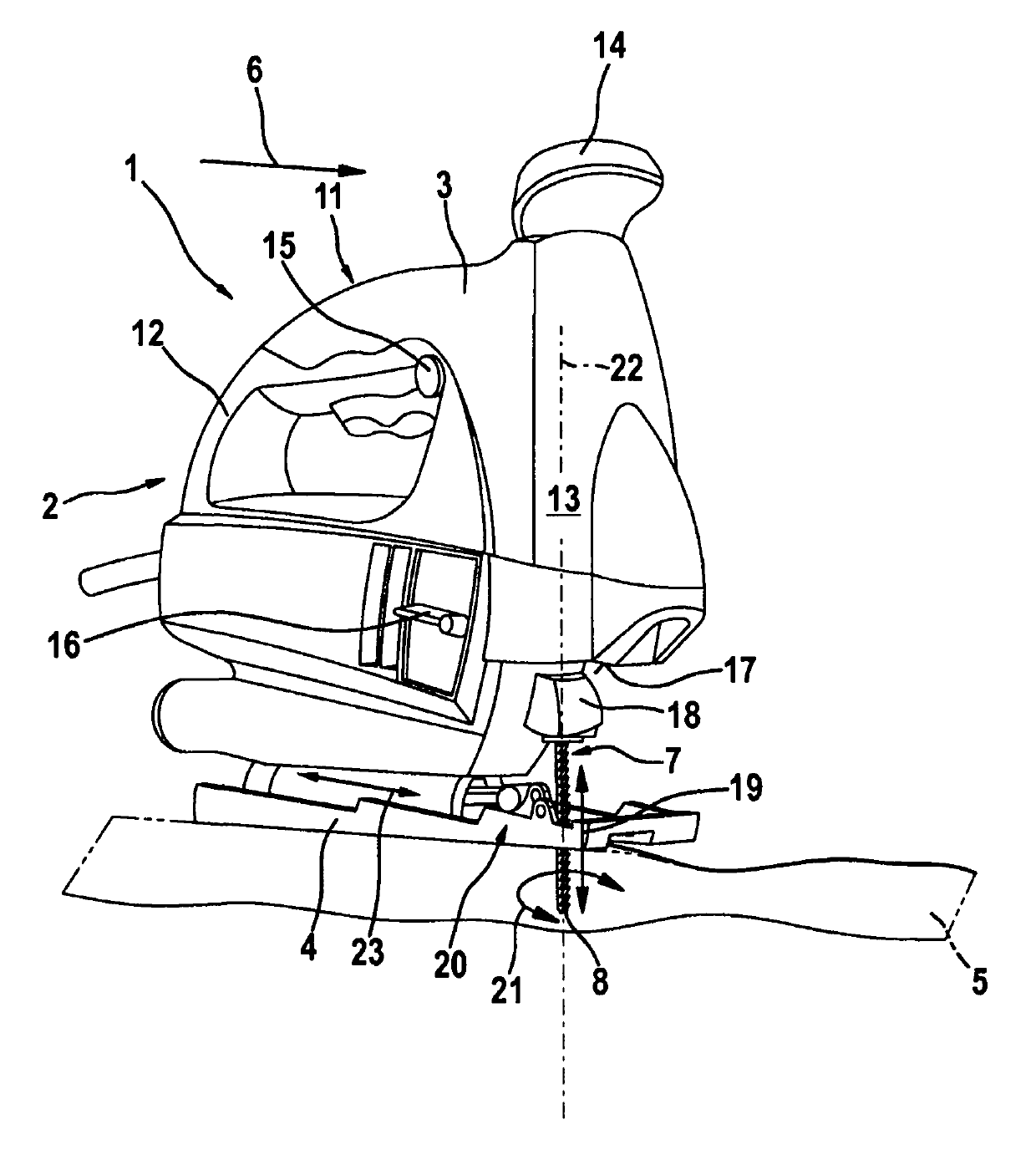

[0019] figure 1 A hand-held machine (as an example of a power tool 1 ) in the form of a jigsaw 2 is shown, which has a housing 3 and is supported via a base plate 4 on a workpiece 5 .

[0020] In the front region of the jigsaw 2 in the working direction 6 , it has a saw blade 8 designed as a working tool 7 . During operation, this saw blade 8 acts on a workpiece 5 on which the jigsaw 2 is movably supported via the base plate 4 .

[0021] On the housing 3 of the jigsaw 2, in the vertical direction, on the opposite side of the base plate 4 (this base plate 4 can be fixedly supported around the pivot axis extending in the working direction 6) is provided with a handle 11, its handle 12 Extends toward the guide handle 14 . A switching device 15 is arranged below the handle 12 by means of which the jigsaw 2 is switched on and off. The different operating modes of the jigsaw 2 are adjusted via the switching device 16 arranged on the longitudinal side of the housing 3 . The end w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com