Synchronizer used for speed change mechanism

一种同步装置、变速机的技术,应用在机械设备、机械驱动离合器、离合器等方向,达到提高操作感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

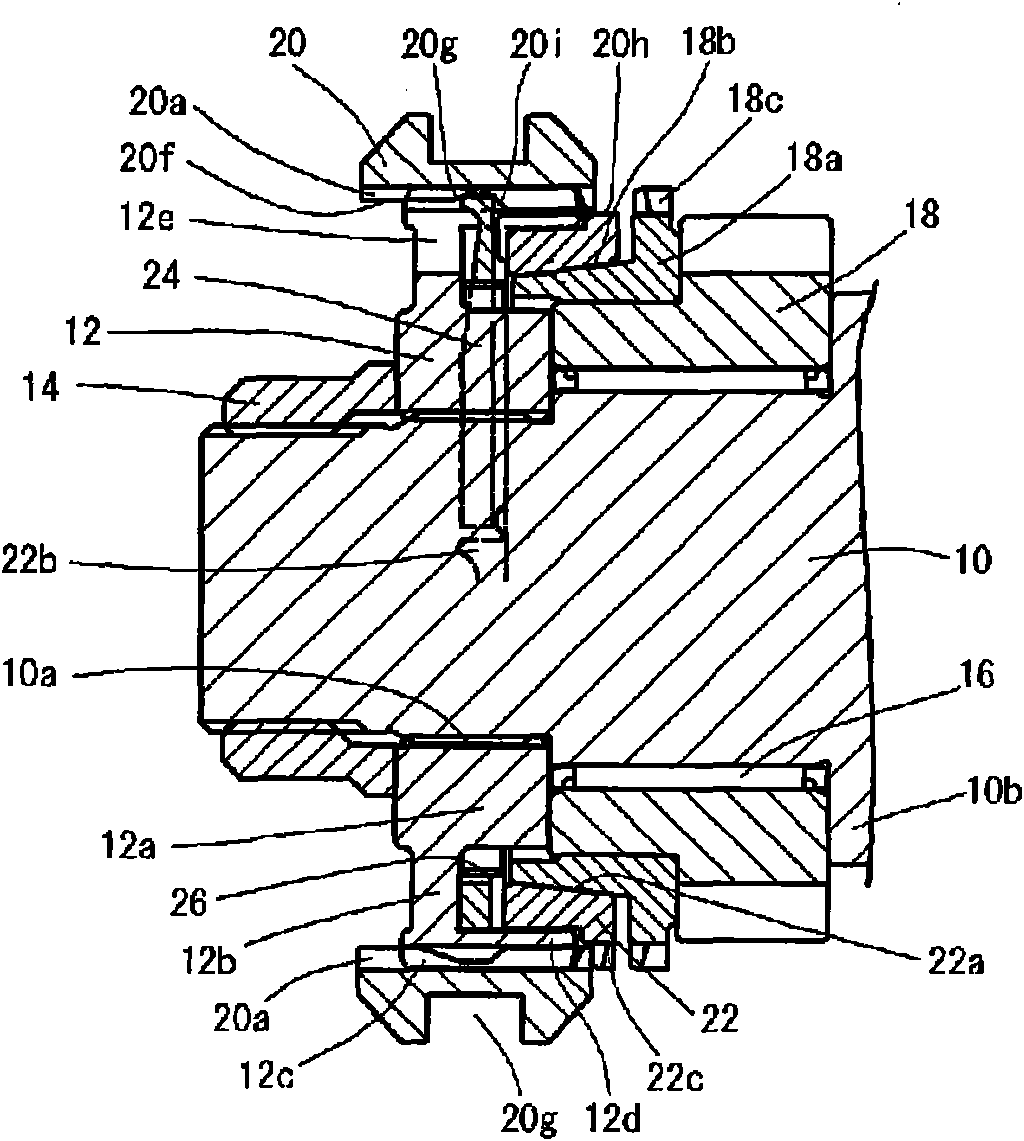

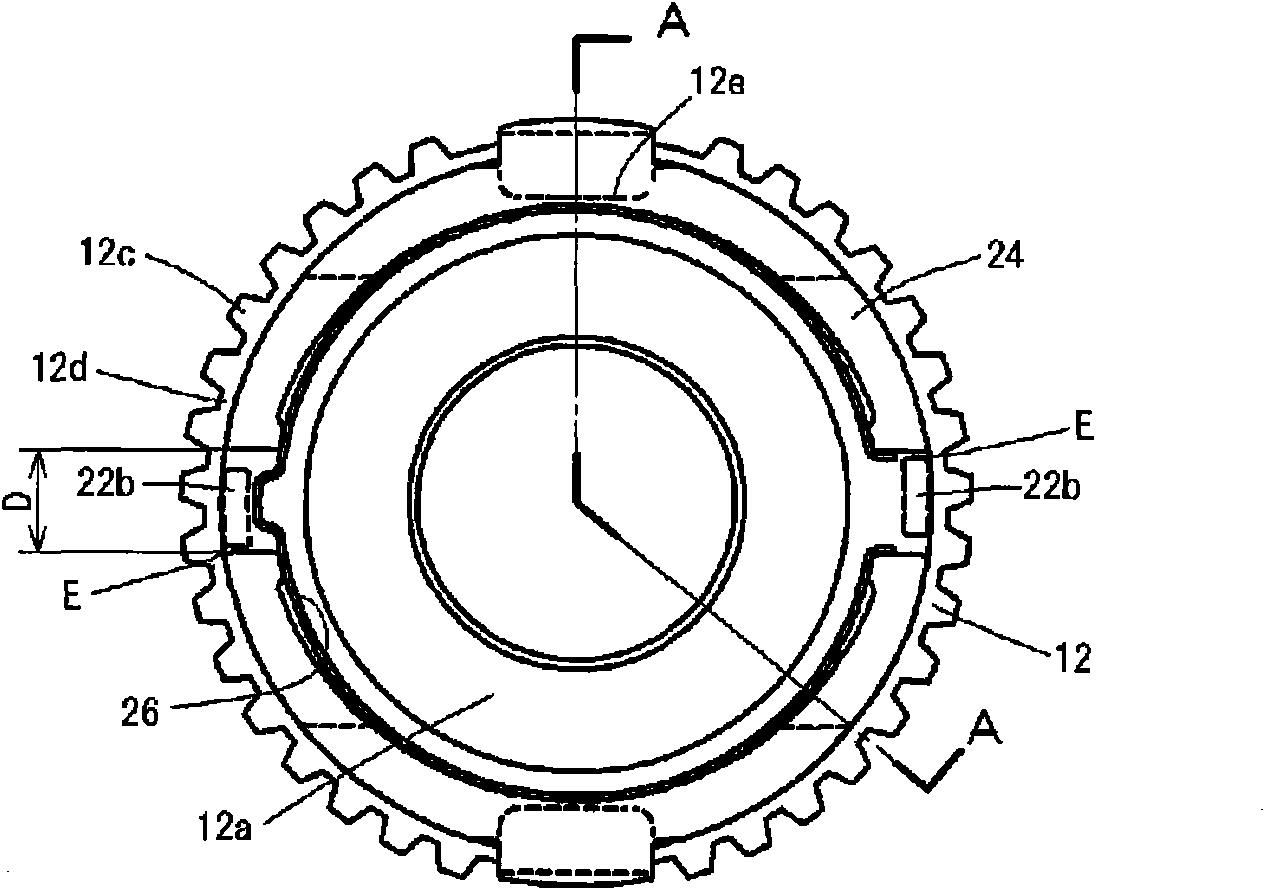

[0028] figure 1 It is a cross-sectional view of the main part of 1 embodiment of the device of the present invention, and is the same as figure 2 The cross-section of the part corresponding to the A-A line. figure 2 is removed figure 1 The output shaft 10, the 5th gear 18, and the synchronizer ring 22 on the 5th gear side in the middle are viewed from the right side (the 5th gear 18 side).

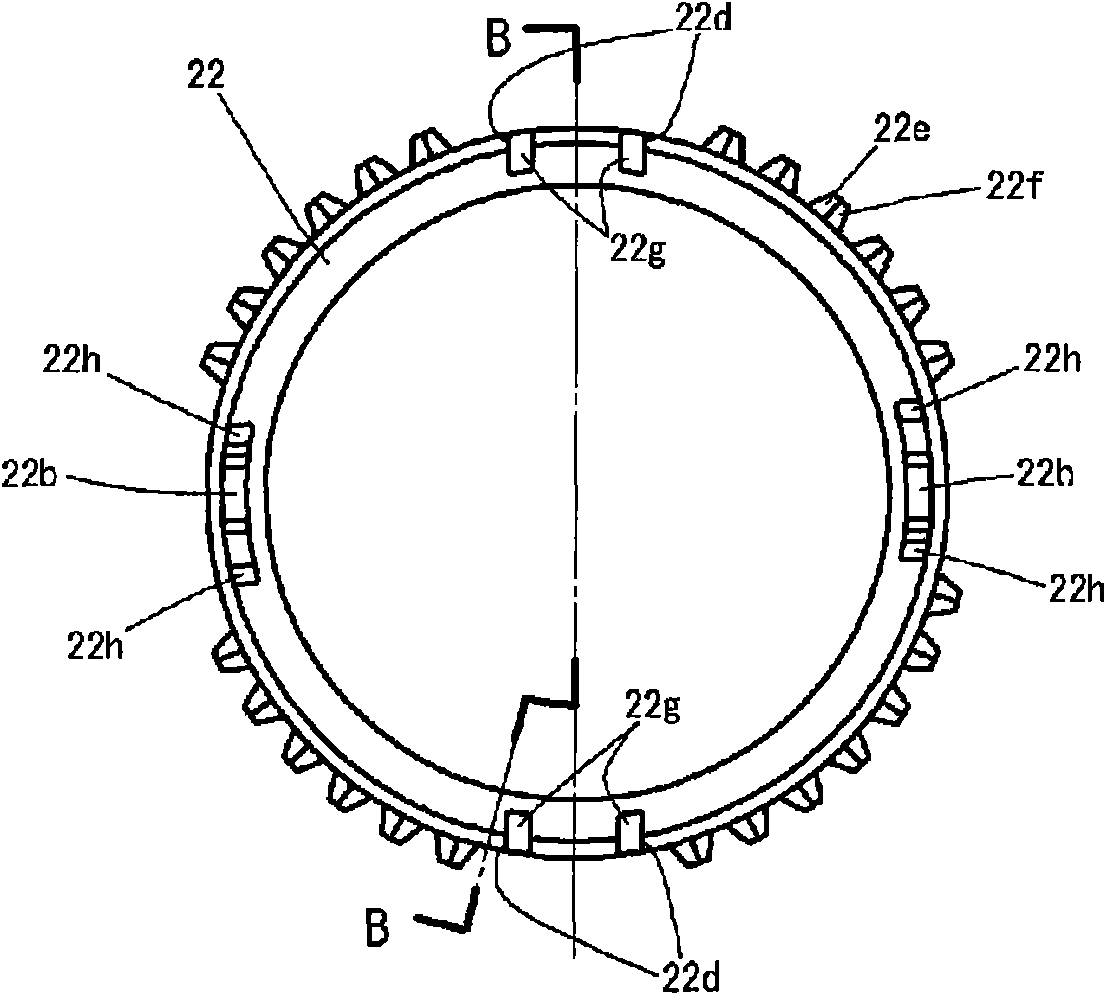

[0029] also, image 3 is the appearance of the synchro ring 22, from figure 1 See the figure on the left. and, Figure 4 express image 3 The section of the synchronizing ring at the line B-B.

[0030] and, Figure 5 is the appearance of the rod member 24, which is obtained from figure 1 See the figure on the left. and, Figure 6 express Figure 5 The section of the rod member 24 at the C-C line.

[0031] also, Figure 7 represents the cross-section of the sleeve 20, Figure 8 A partially enlarged section of the sleeve 20 is shown.

[0032] The output shaft 10 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com