Transmission rod convenient for truncating

A transmission rod and transmission tube technology, which is applied in the field of transmission rods, can solve the problems of lengthening the transmission rod and delay the progress of the project, and achieve the effect of simple structure and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

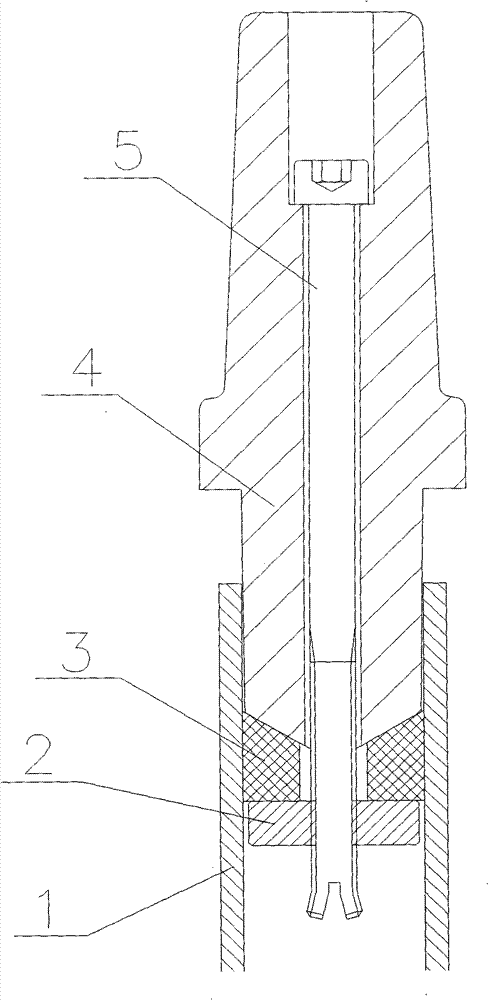

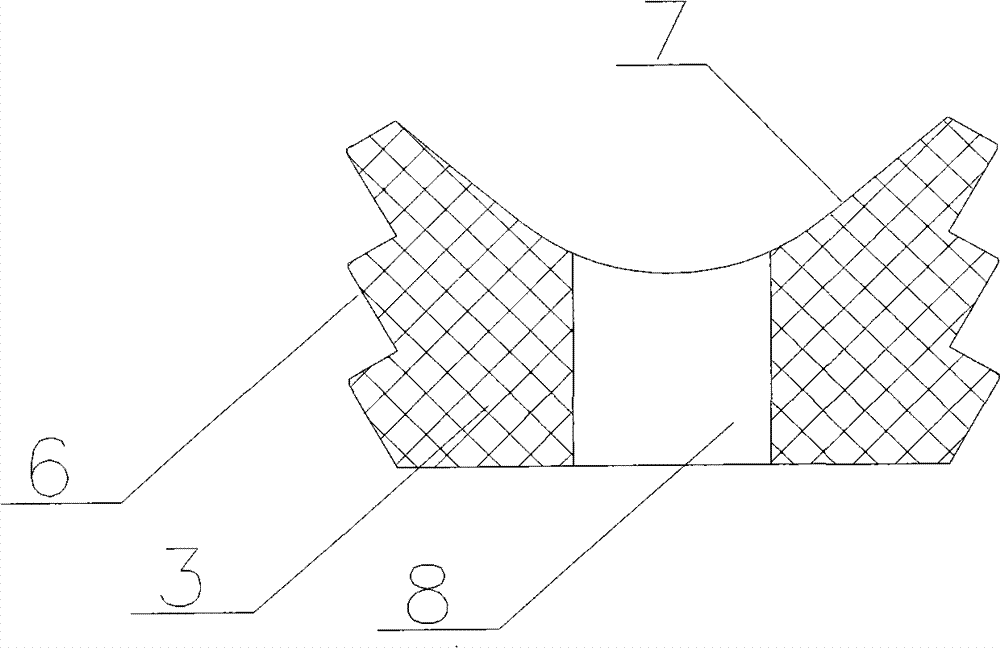

[0020] Such as figure 1 , figure 2 As shown, a transmission rod that is convenient to be shortened includes a transmission cap assembly and a transmission pipe 1, wherein the transmission cap assembly includes a nut 2, a compression plug 3, a transmission cap 4, and a screw 5. The transmission pipe 1 is a square pipe, and its length can be determined after calculation according to the predetermined buried depth of the valve. Described nut 2 is square, and the center is provided with threaded hole. The compression plug 3 is a square rubber block with a V-shaped slope 7 on the top, toothed sides 6 on both sides, and a through hole 8 in the middle. One end of the transmission cap 4 is square-conical, the other end is square, and a countersunk bolt hole is arranged in the middle. The screw 5 is a countersunk screw with a flat groove at the end. The screw 5 passes through the transmission cap 4, the nut 2 is screwed on the other end, and the compression plug 3 is clamped in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com