Cooling appliance storing coolant in the condenser, and corresponding method

A technology of refrigeration appliances and condensers, which is applied in the direction of compressors with multiple condensers, refrigeration and liquefaction, and compressors with multiple evaporators, which can solve problems such as high cost and achieve optimal cooling systems, To achieve the effect of overvoltage protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

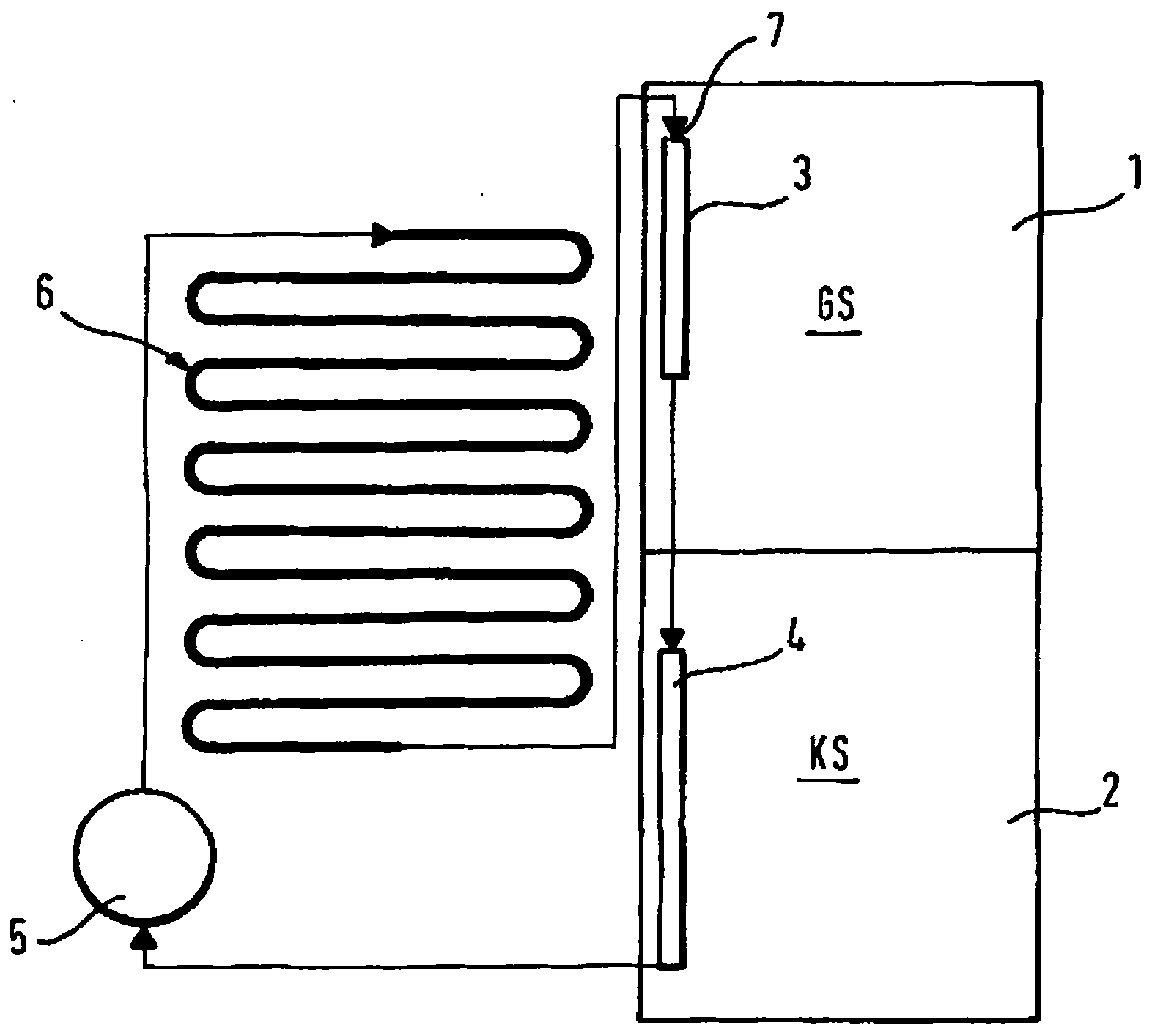

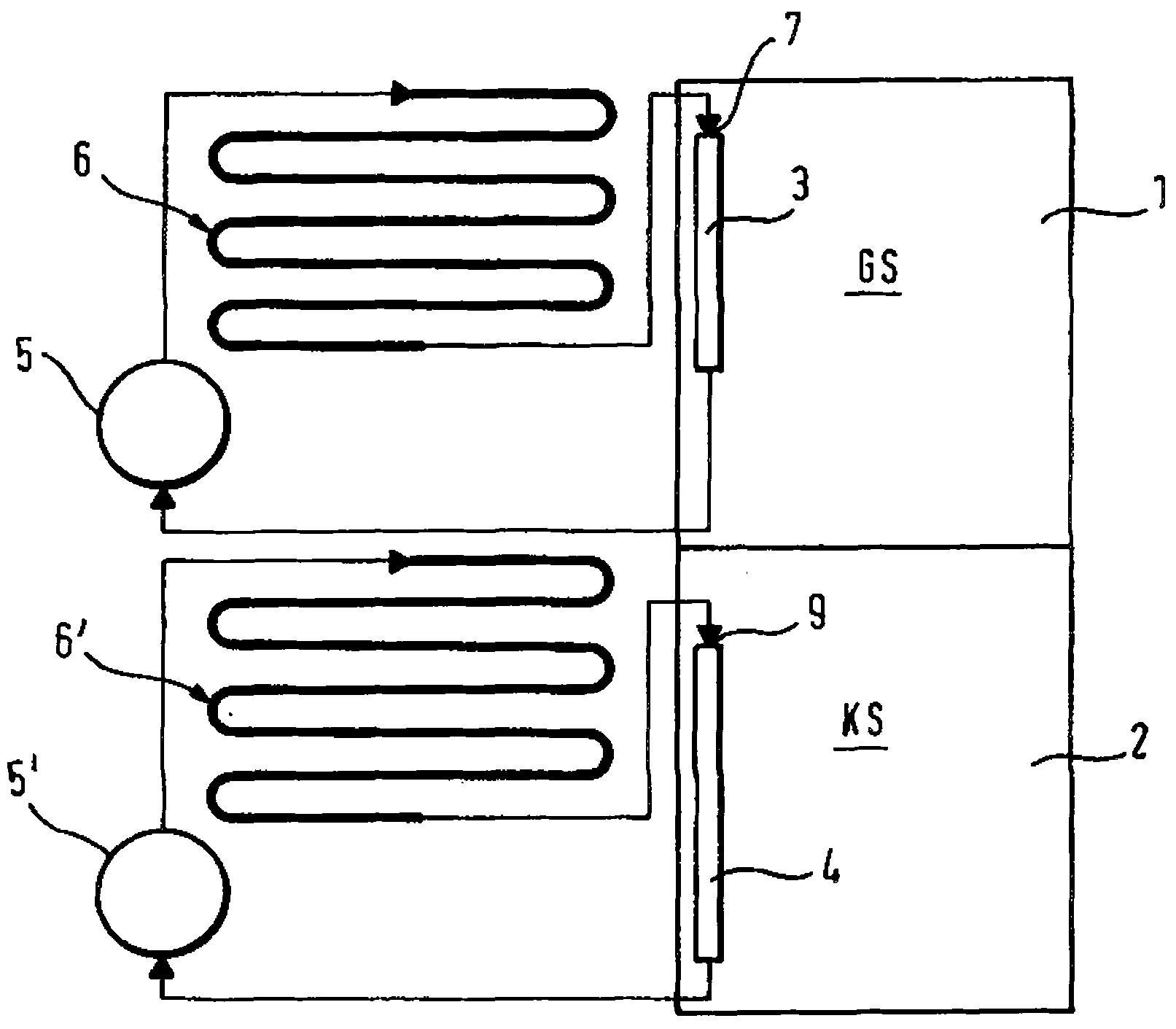

[0035] based on Figure 5 The exemplary embodiment shown is a preferred implementation of the invention. However, for a better understanding of the present invention, first another double loop system is explained.

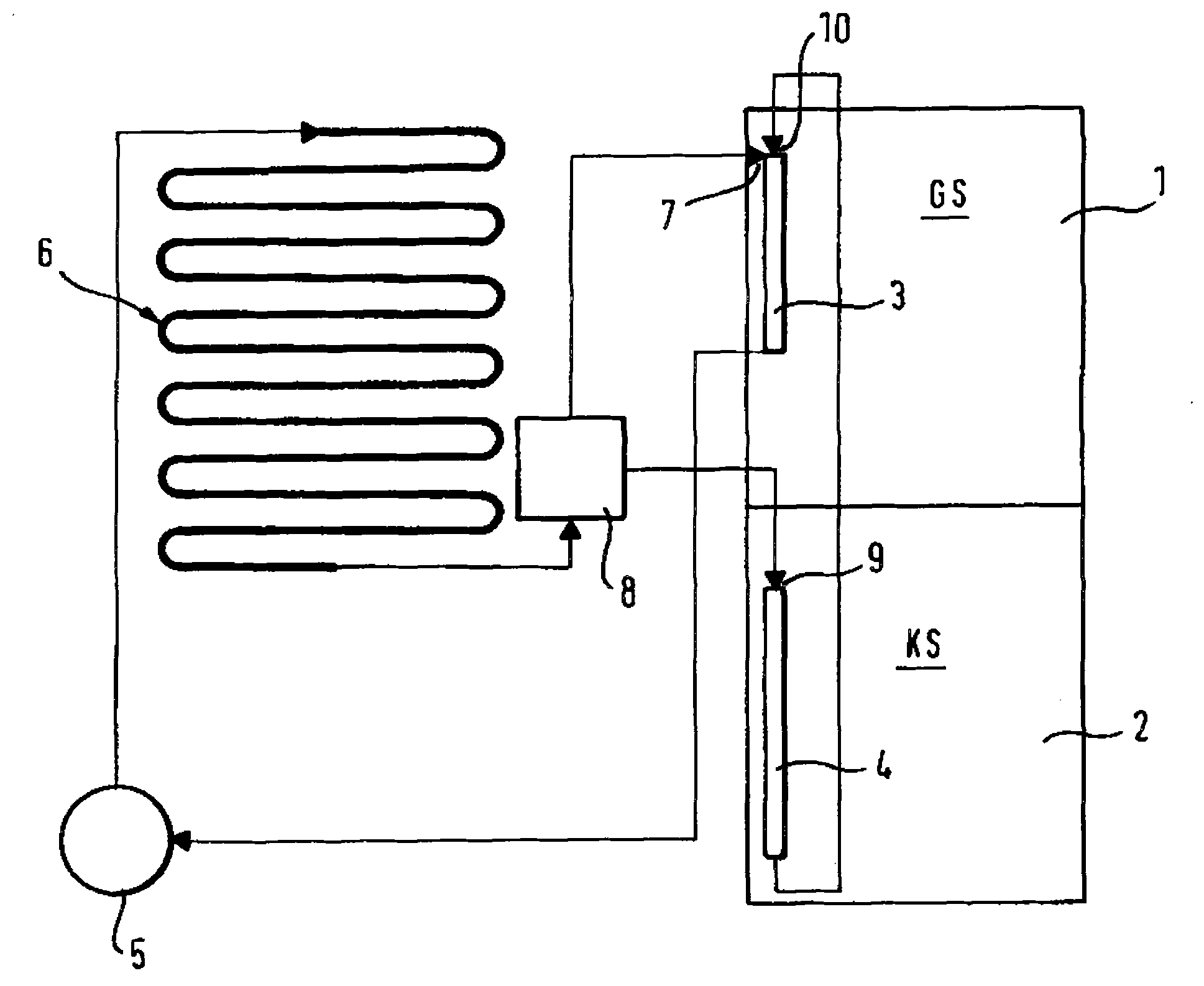

[0036] First, it should be explained that, in accordance with figure 2 Why can't the two compartments be shut off independently in the dual circuit system. A solenoid valve 8 makes it possible to switch between the two circuits. When the freezer compartment 1 is activated, refrigerant is injected into the freezer compartment or its evaporator 3 and is sucked directly from there to the compressor 5 . In contrast, when the refrigerated compartment is activated, refrigerant is injected into the refrigerated compartment evaporator 4 . There, however, it is conducted to the freezer compartment evaporator 3 and sucked through the entire freezer compartment evaporator 3 to the compressor 5 . This means that when the refrigerated compartment is activated, the freezer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com