Electrical and optical system and methods for monitoring erosion of electrostatic chuck edge bead materials

An electrostatic chuck and electrical technology, applied in the direction of electrical components, circuits, discharge tubes, etc., can solve the problems of particle generation, harmful effects on device yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

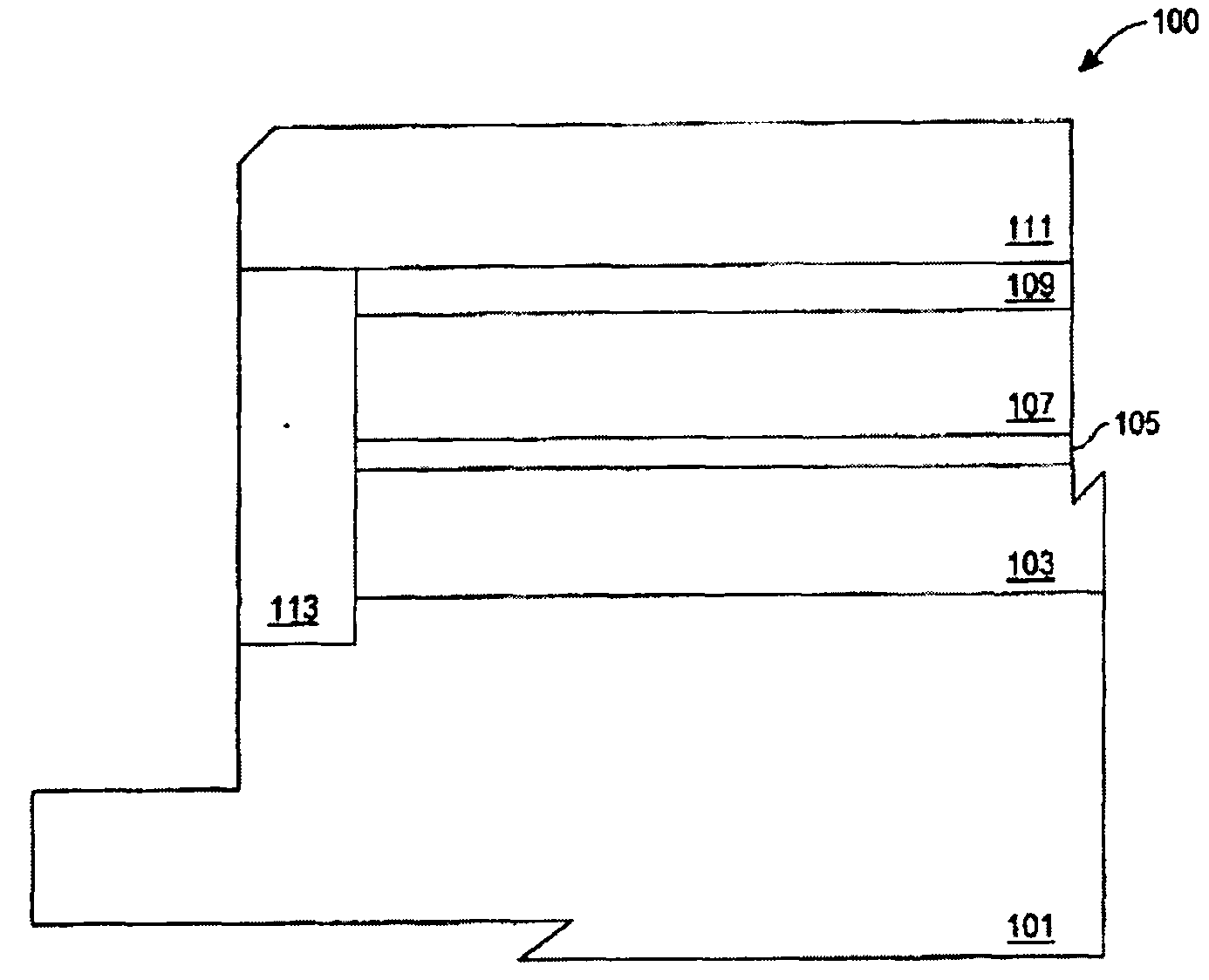

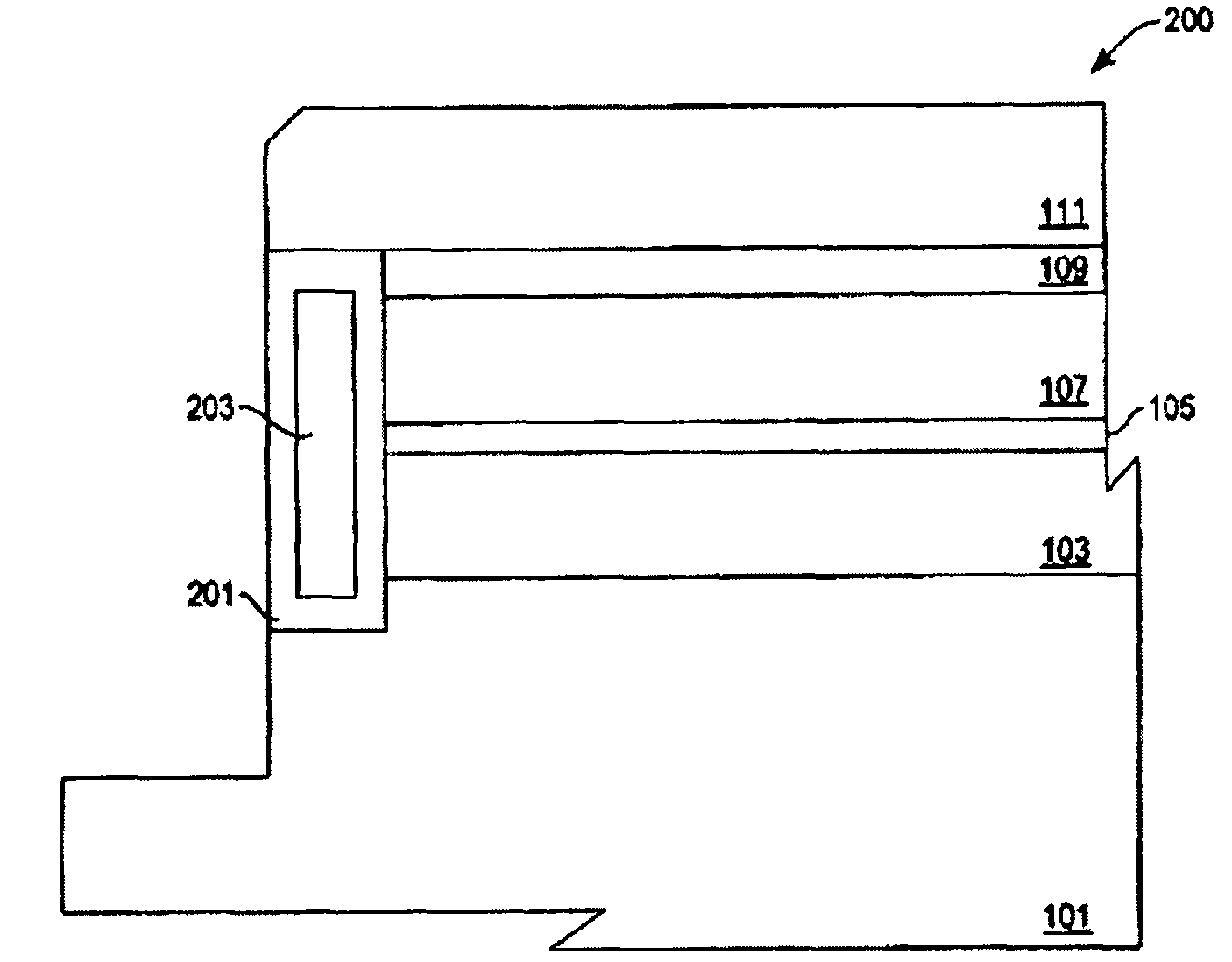

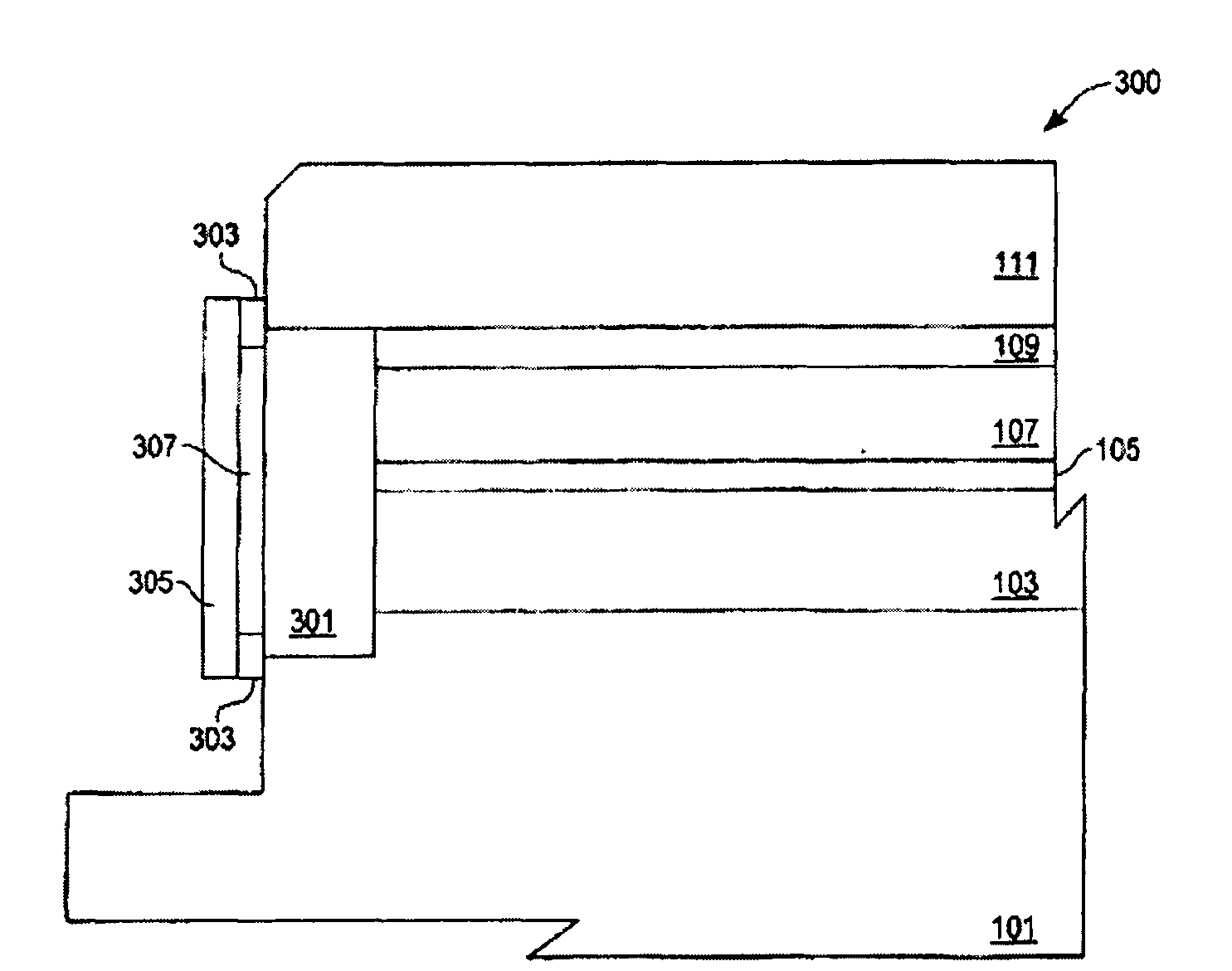

[0021] The various embodiments discussed below disclose a tool for monitoring when the edge adhesive seal inside the ESC is corroded, thereby protecting the heater and other adhesive layers. Various embodiments disclose the monitoring tape or layer in the edge bead of the ESC, which has an independent erosion indicator or an indicator combined with various optical or electrical monitoring instruments. When the monitoring layer is exposed to plasma, it interacts with plasma species to produce volatile chemicals that can be detected by, for example, an optical emission spectroscopy (OES) system.

[0022] In other embodiments, the change of the monitoring layer can be detected by a simple reflectance or optical scattering system. The design of these and related optical measurement systems is known in the art.

[0023] Alternatively, because the plasma erosion reaction changes the measurement resistance of the conductive layer, the resistance of the monitoring layer can be measured. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com