Gravity center follow-up balance compensating device of floor type boring and milling machine

A technology of balance compensation, milling and boring machine, applied in metal processing mechanical parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problem of not being able to adjust the cost of center of gravity at the same time, and achieve easy implementation and control, simple structure, and elimination of Effect of deflection deformation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with embodiments, but the protection scope of the present invention is not limited thereto.

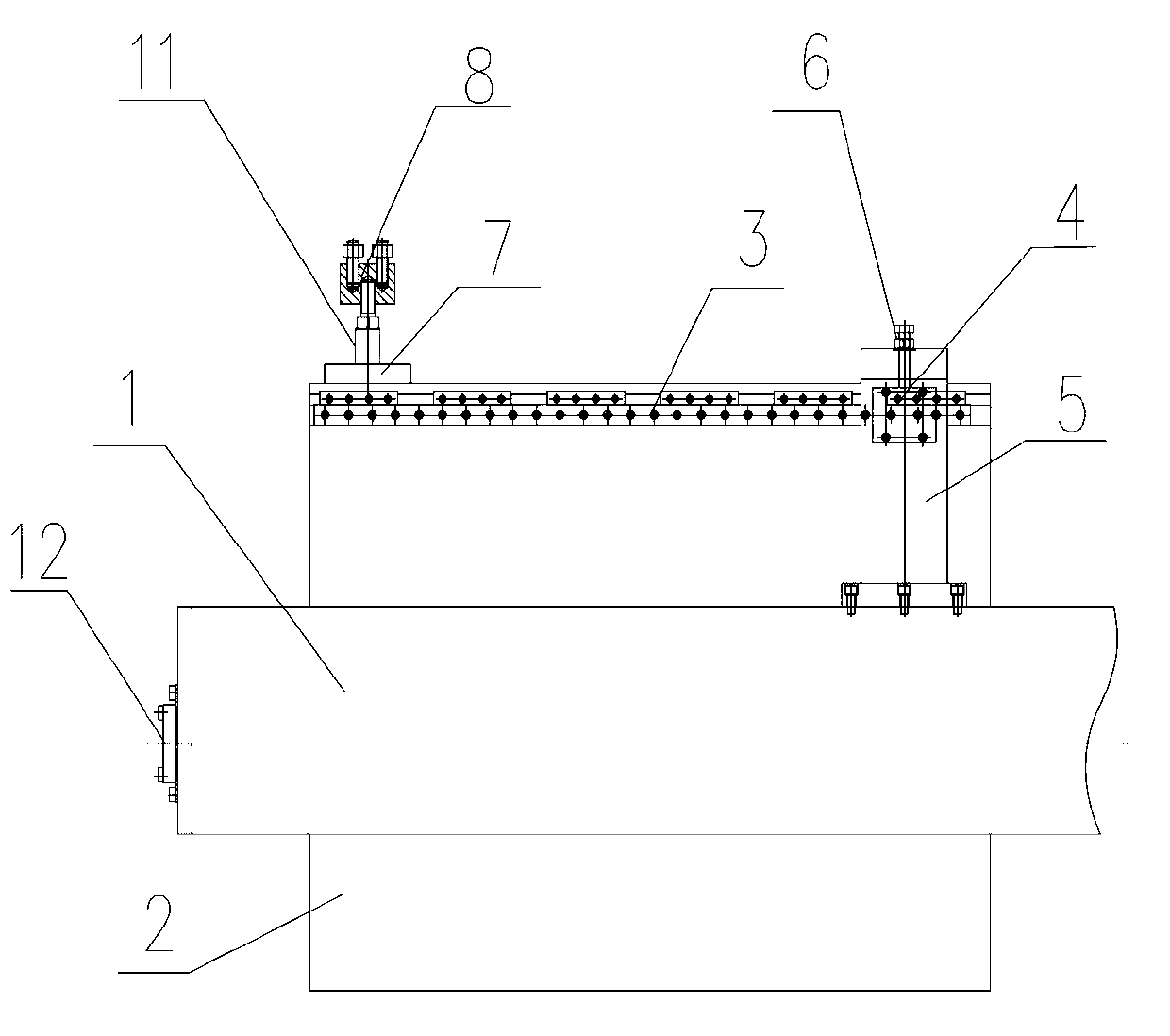

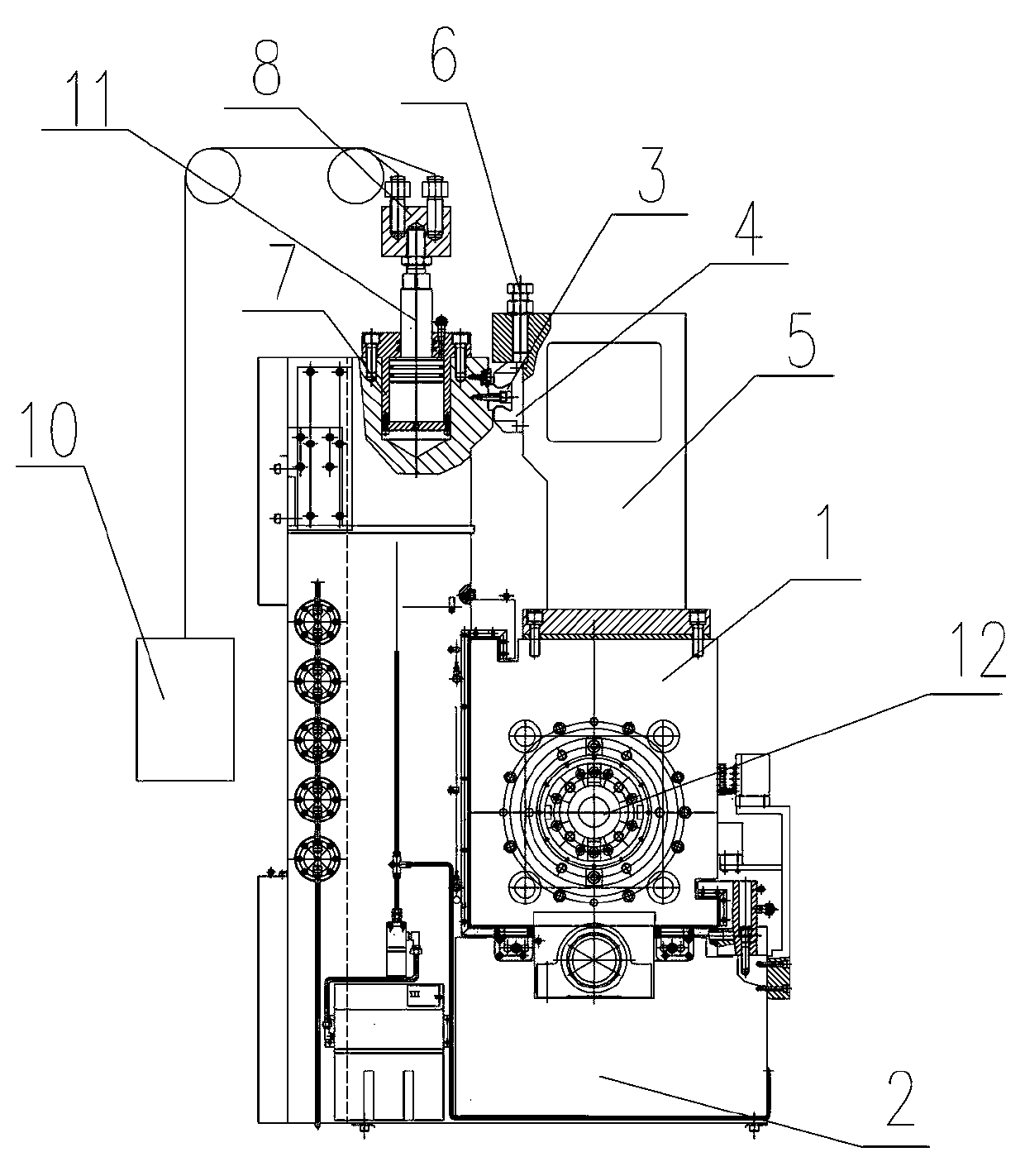

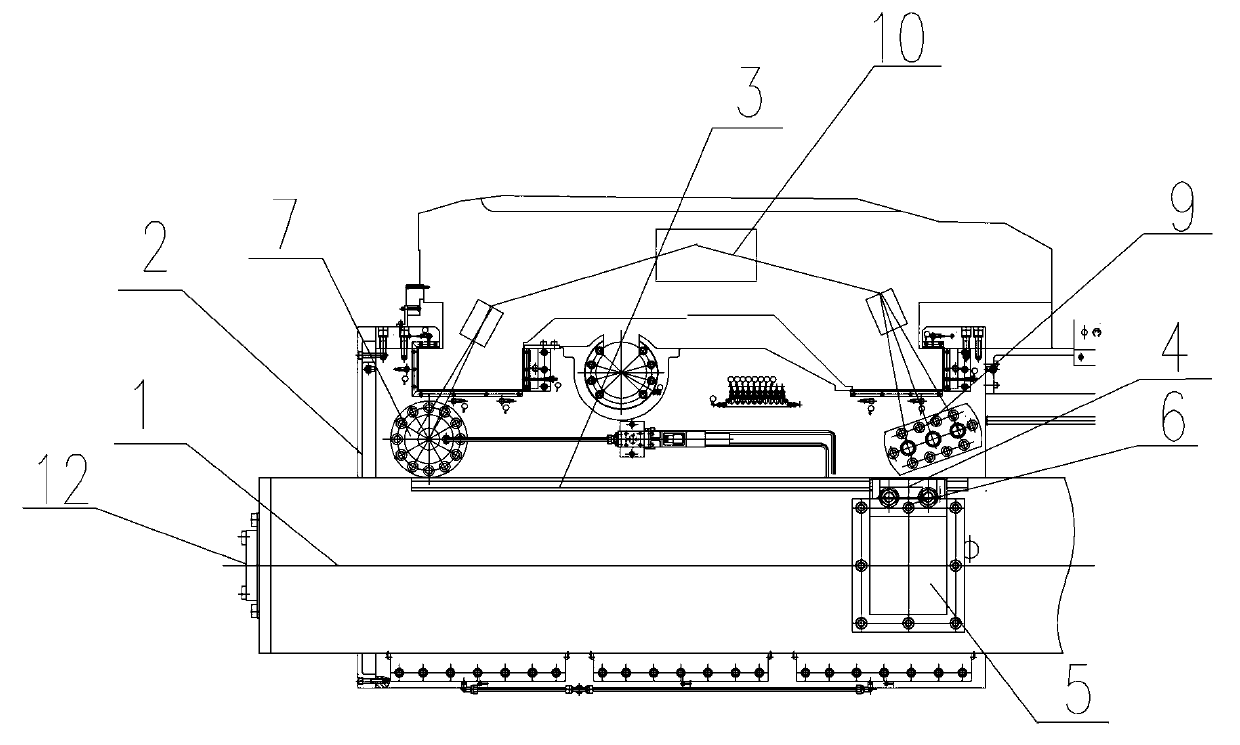

[0018] Such as Figure 1-3 As shown, the present invention relates to a center of gravity follow-up balance compensation device for a floor-standing milling and boring machine. The floor-standing milling and boring machine includes a ram 1 and a ram seat 2, and the center of gravity follow-up balance compensation device includes a ram balance compensation device. The ram balance compensation device includes a guide rail 3 arranged on the upper part of the ram seat 2, a slider 4 matched with the guide rail 3, and a hanger 5. The hanger 5 is fixedly connected to the ram 1 and is perpendicular to the ram. 1 On the center of gravity line in the moving direction, the hanger 5 is threadedly connected with the slider 4.

[0019] The ram 1 is provided with a work spindle 12, and the work spindle 12 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com