Printing apparatus and printing method

A printing device and one-party technology, applied in printing and other directions, can solve the problems of different hues, density, uneven printed images, and reduced image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] ===Disclosure Summary===

[0016] At least the following can be understood from the description of this specification and the description of the drawings.

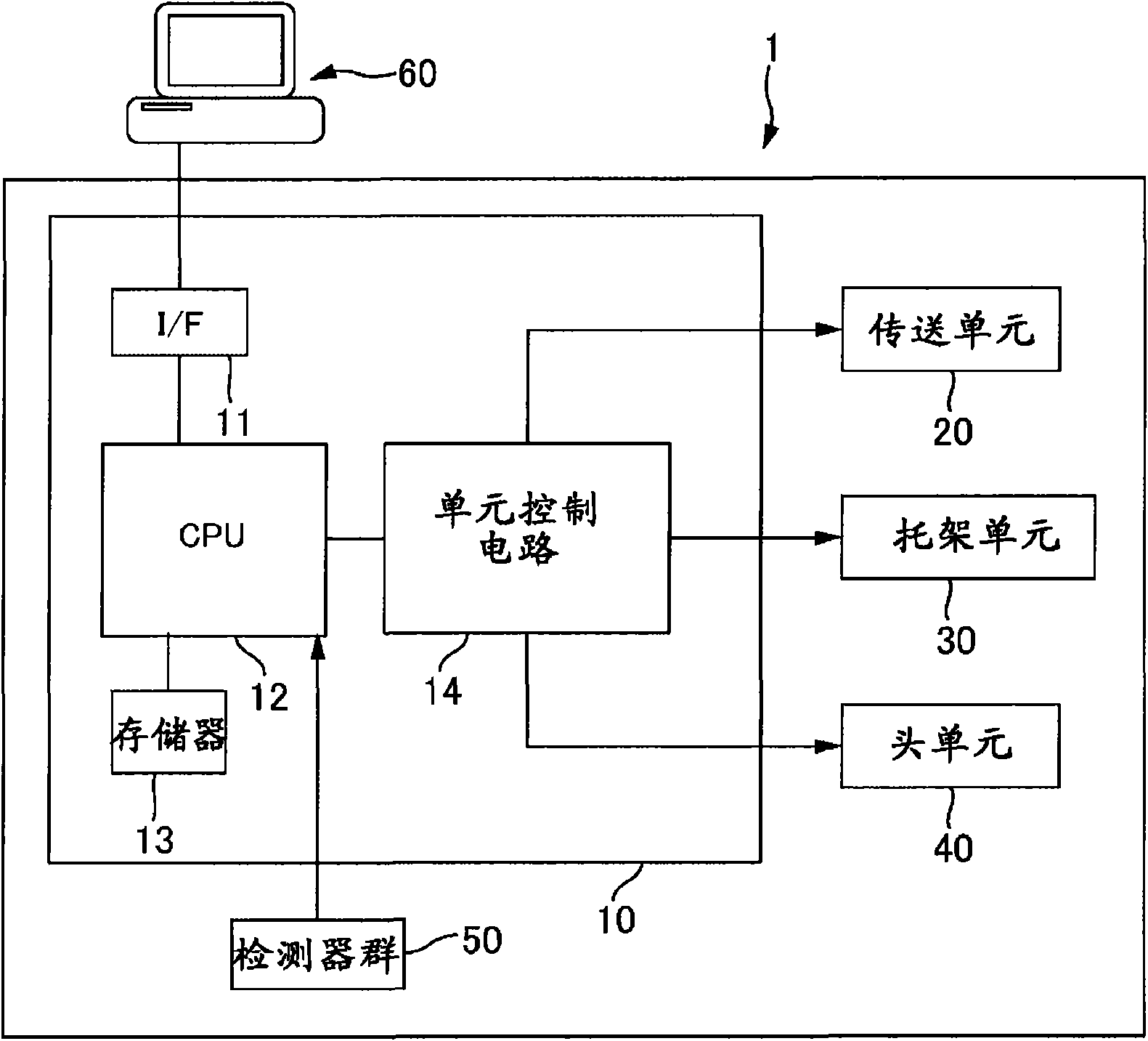

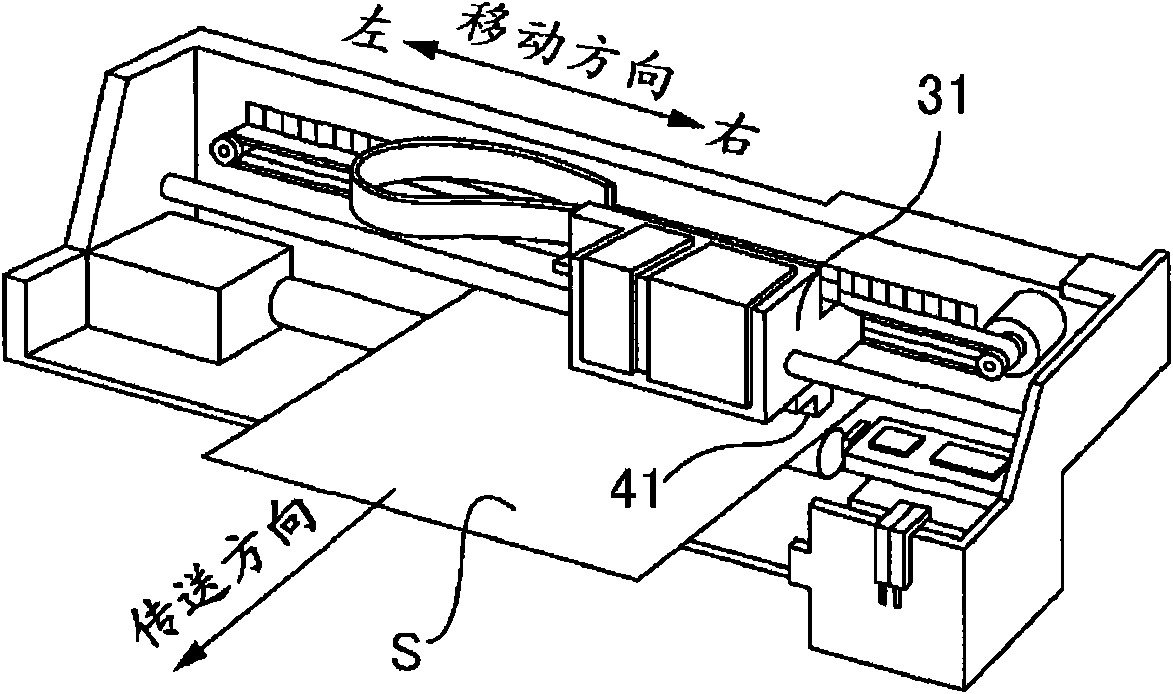

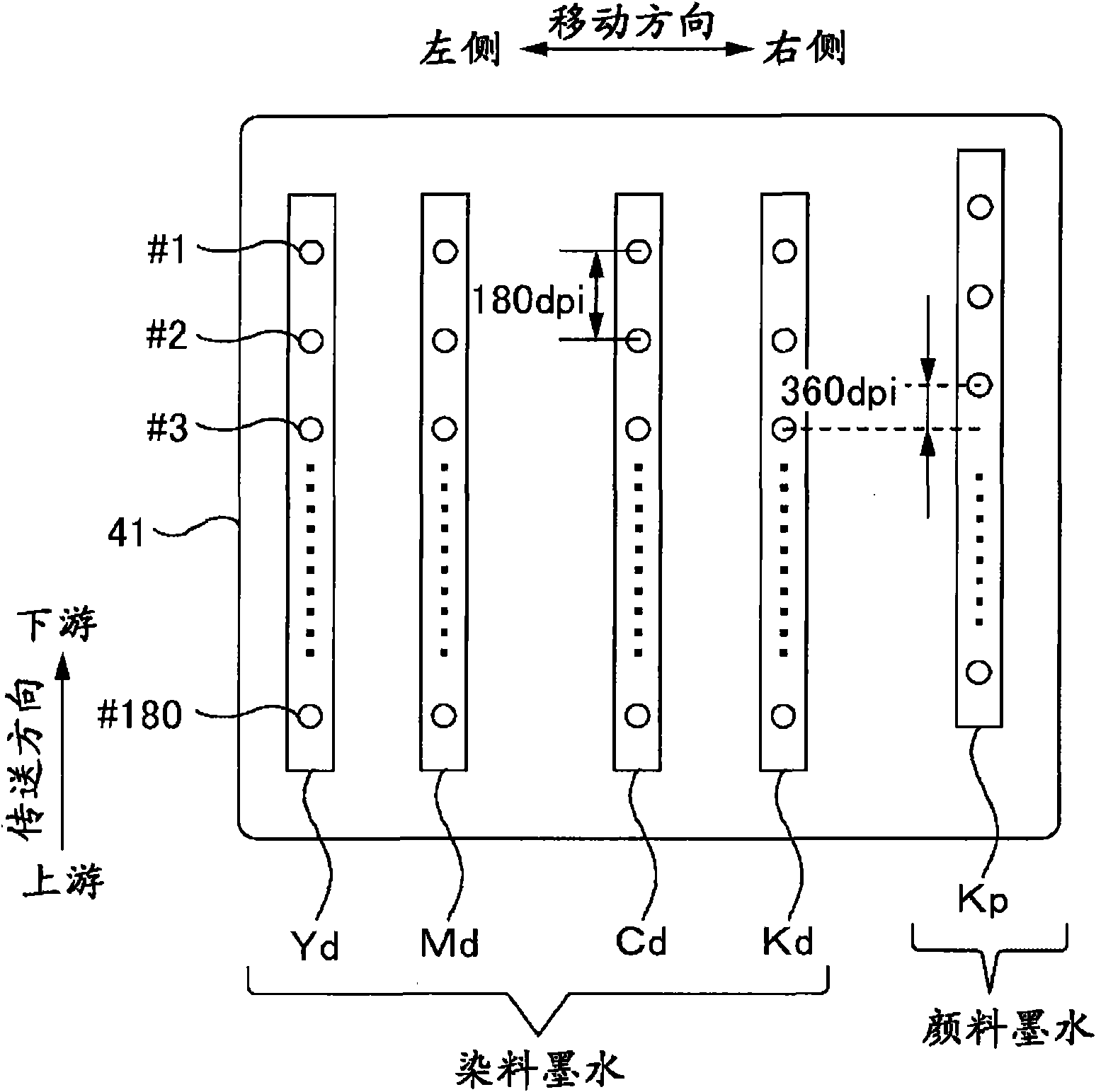

[0017] That is, a printing apparatus characterized by comprising: a first nozzle row in which nozzles for discharging dye ink of a certain color are arranged in a predetermined direction; nozzles for discharging pigment ink of the certain color are arranged in the predetermined direction. a second nozzle row; and a control unit that repeatedly performs a discharge operation of discharging ink from the nozzles while relatively moving the first nozzle row and the second nozzle row and the medium in a moving direction intersecting the predetermined direction and making the above-mentioned The transfer operation of the first nozzle row and the second nozzle row and the medium relative to the above-mentioned predetermined direction is performed by moving the first nozzle row and the second nozzle row and the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com