Web jointing apparatus, web jointing method, and functional film manufacturing method

A jointing device and jointing method technology, which is applied in the direction of thin material processing, sending objects, winding strips, etc., can solve the problems of discomfort and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

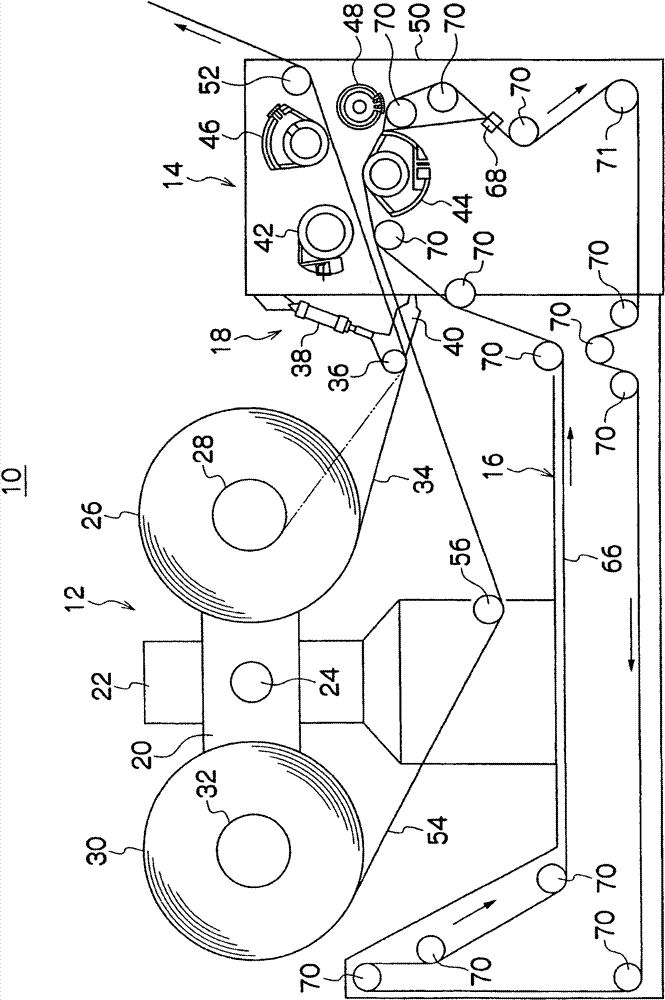

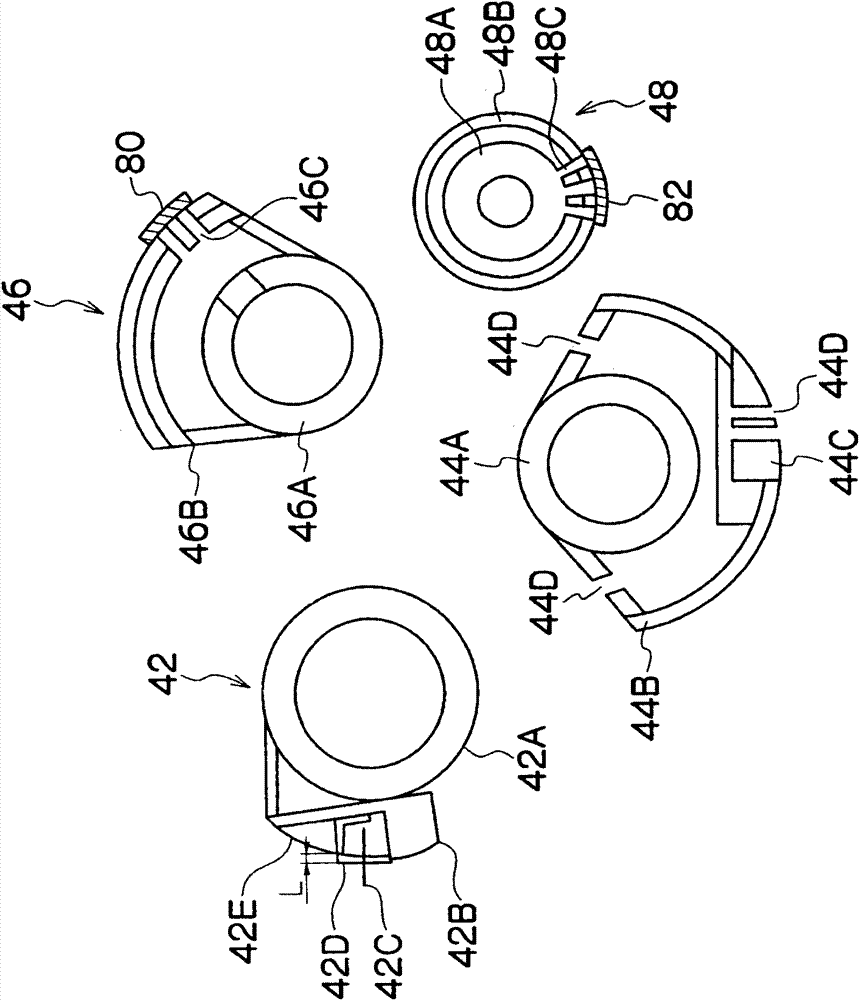

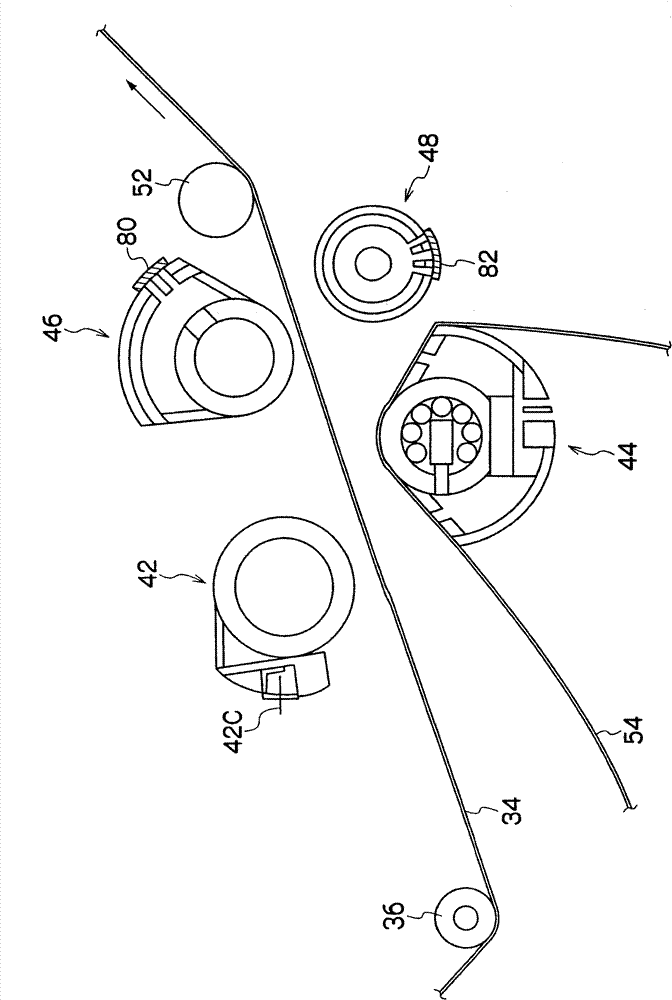

[0088] On the surface of the reel 34 of the old roll 26 sent out at 30m / min by a rod coater with 15cc / m 2 A coating liquid having firm coating properties is applied, dried at 80° C. for 3 minutes, and the dried roll 34 is wound up by the winding device 64 . Next, use figure 1 The illustrated web splicing device 10 performs butt splicing of webs. The upper blade drum 42 has a diameter of 351.9 mm, the lower blade drum 44 has a diameter of 351.9 mm, and the first engagement drum 46 has a diameter of 352.5 mm. The level difference of the surface of the upper blade drum 42 was 5 mm. As the roll, TAC (triacetyl cellulose) having a width of 1490 mm and a thickness of 80 μm was used.

[0089] The joint portion formed by the rear end of the old roll and the front end of the new roll and the front end of the cut old roll were visually observed with a light scope. Figure 15 Indicates the observation result. Such as Figure 15 As shown, scratches 100 are hardly observed within 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com