Crane with a boom tensioning device

A crane and jib technology, applied in the field of cranes, can solve problems such as inability to achieve three-dimensional tensioning, and achieve the effects of improving lateral tensioning and good three-dimensional tensioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

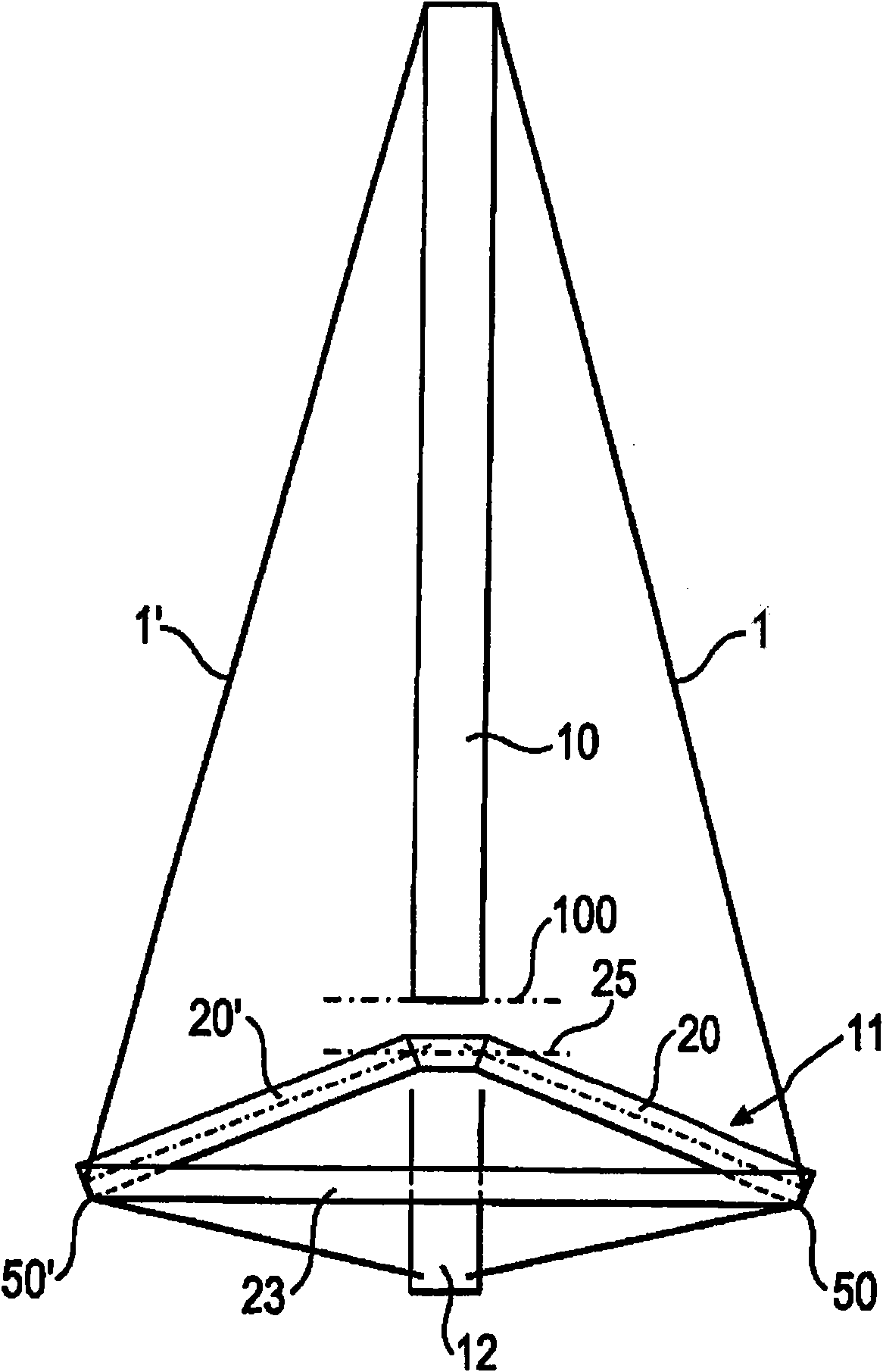

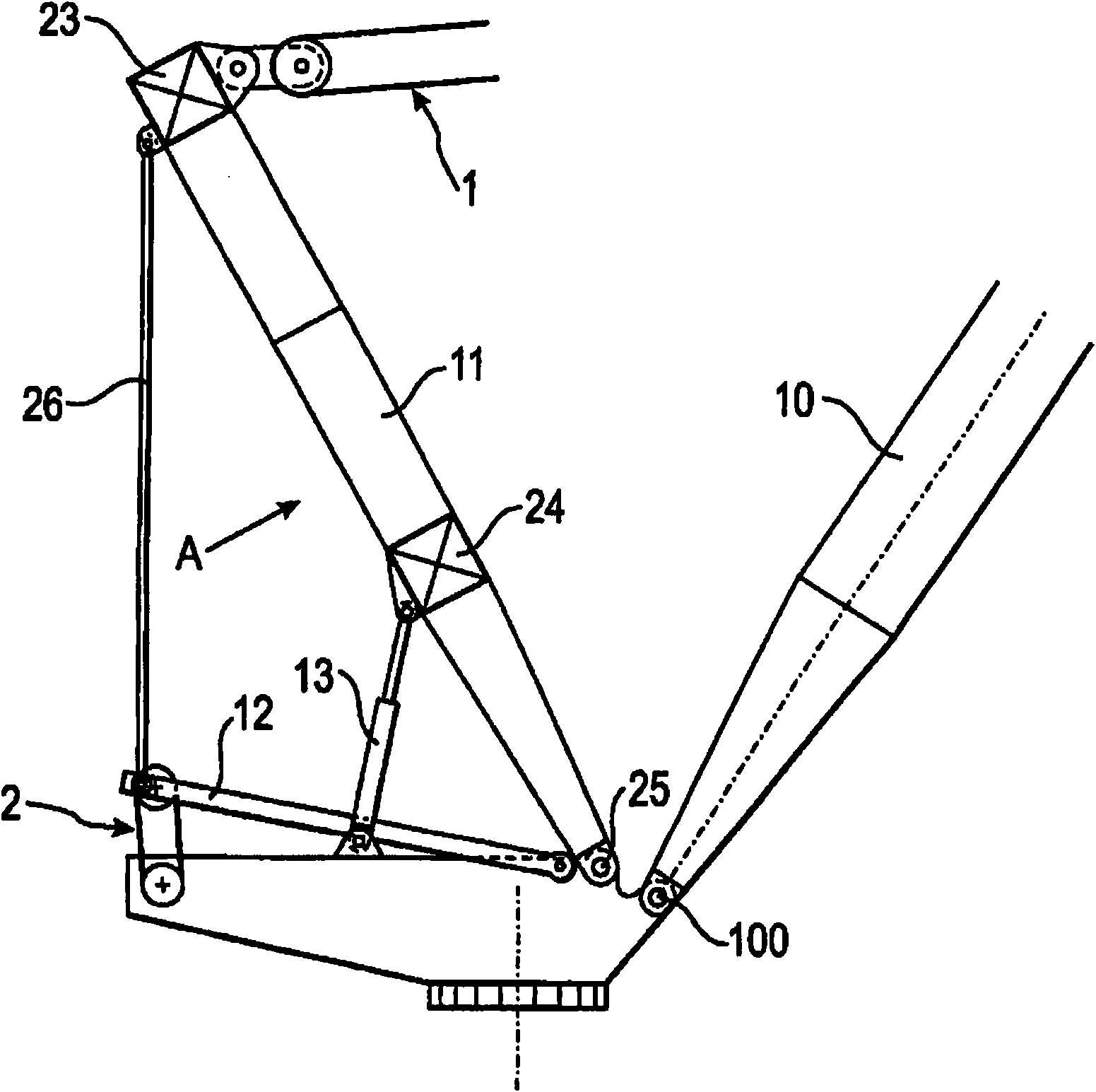

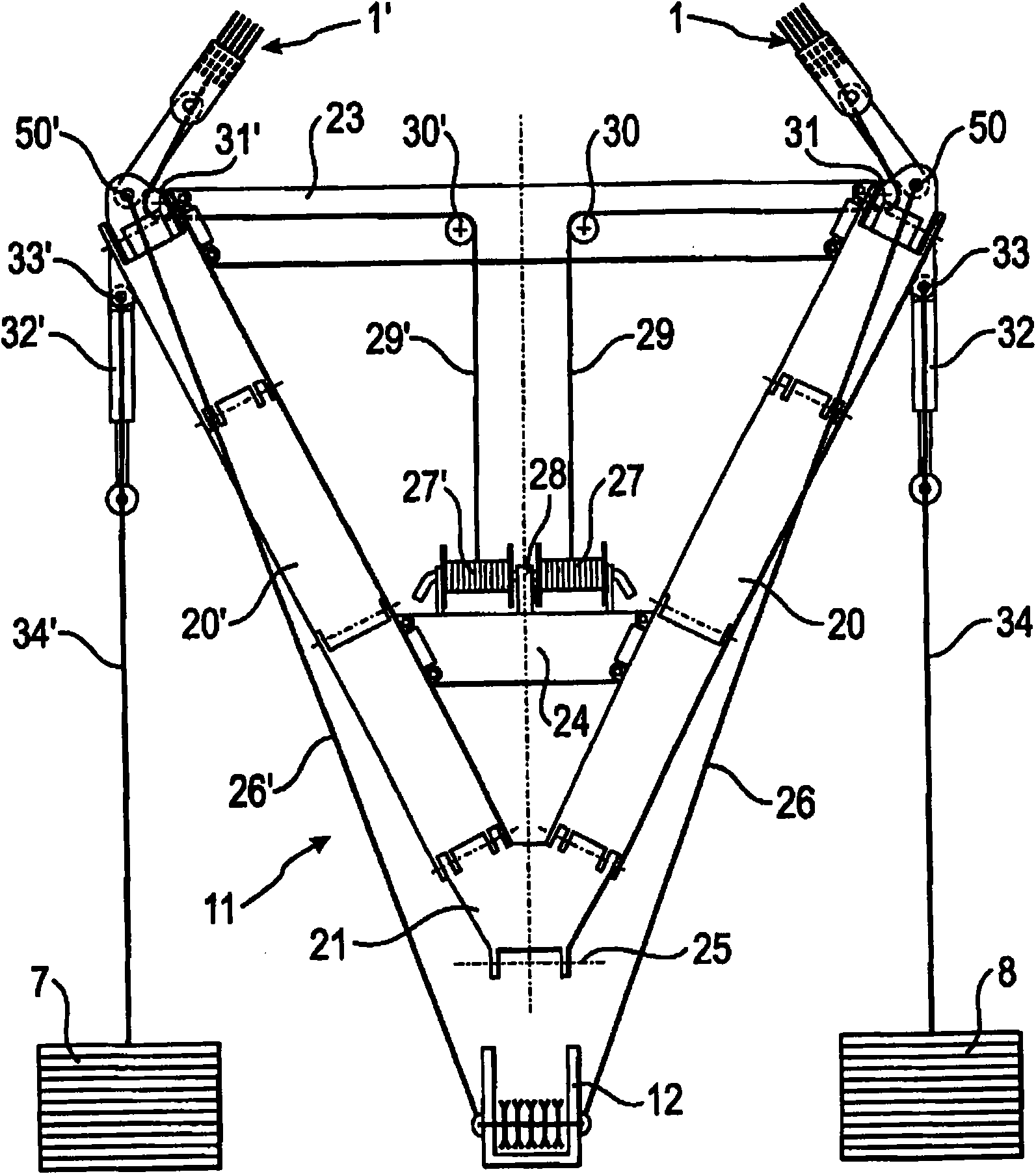

[0042] figure 1 An embodiment of the crane according to the invention is shown in plan view. Here, a main boom 10 is provided, which is mounted pivotably about an axis 100 on the upper carriage. In addition, a cable jib mechanism 11 is provided, which is likewise articulated on the upper carriage. The main boom 10 may now be in the form of a truss jib.

[0043] Furthermore, the boarding itself is in figure 1 is not shown. The entry carriage is now mounted on an exit carriage, also not shown. Furthermore, a running gear is provided on the lower carriage 52 for traveling the crane, for example a crawler running gear or a plurality of axles with tires.

[0044] A cable winding system is provided between the cable jib mechanism 11 and the main boom 10 . The cable reel system now comprises a first cable 1 which extends from a tension point 50 on the cable jib mechanism 11 to the main boom 10 . Furthermore, the cable reeling system comprises a second cable 1' which extends fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com