Method for realizing position sensor interface supporting various sensor communication protocols

A sensor interface and communication protocol technology, applied in the field of servo control, can solve the problems of increasing the difficulty of on-site debugging by technicians, and the inability to support sensor protocols, etc., and achieve the effect of convenient on-site debugging and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

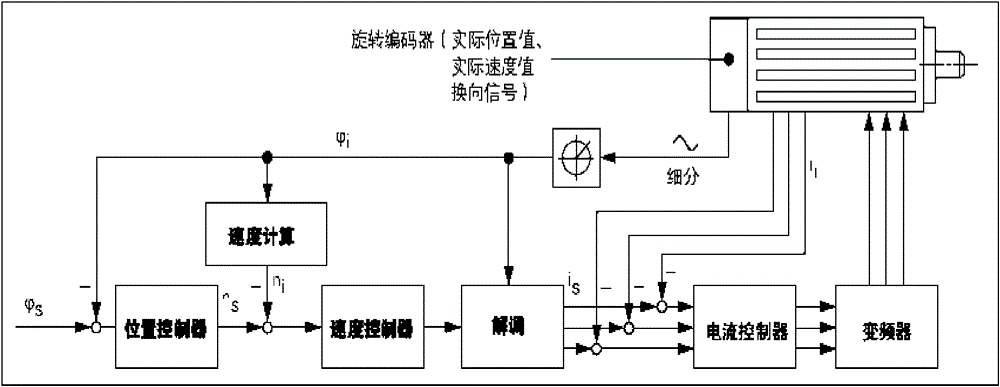

[0047] Figure 4 It is a schematic diagram of the structure of the servo control system of the position sensor interface that supports multiple sensor communication protocols in the present invention. The system includes: CPU module, FPGA module, 485 chip and position sensor interface, wherein the CPU module is connected with the FPGA module, and the FPGA module They are respectively connected with two 485 chips, and the position sensor is connected with two 485 chips respectively. Among them, the CPU module is only used to read and write the position sensor data and other information cached in the FPGA module. The CPU module is mainly used for specific applications after reading the position sensor data, such as applications such as motion control. The CPU module accesses the FPGA module through the data, address, and read-write control bus; the FPGA module plays a central role in this method, not only realizing the function of automatically identifying various position senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com