Leveling control system and method for aerial work platform

A technology of aerial work platform and control method, which is applied in the direction of comprehensive factory control, load suspension components, lifting devices, etc., can solve the problems of platform jitter and poor responsiveness, and achieve the advantages of small platform jitter, improved stability, and improved responsiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

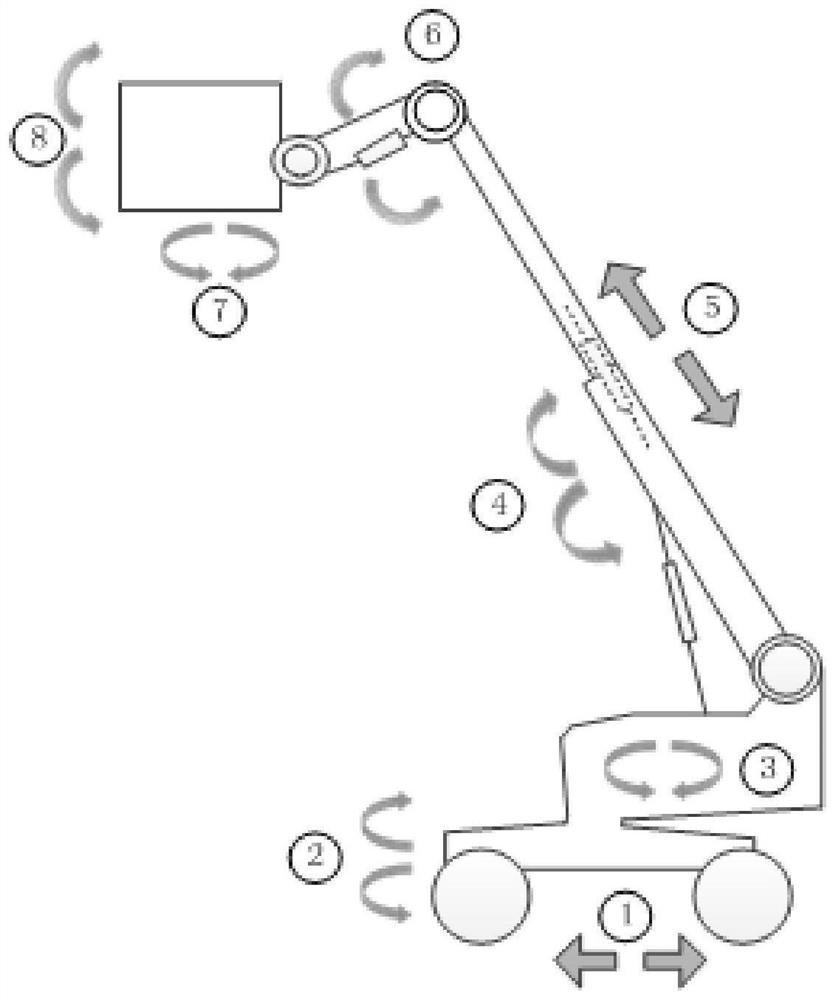

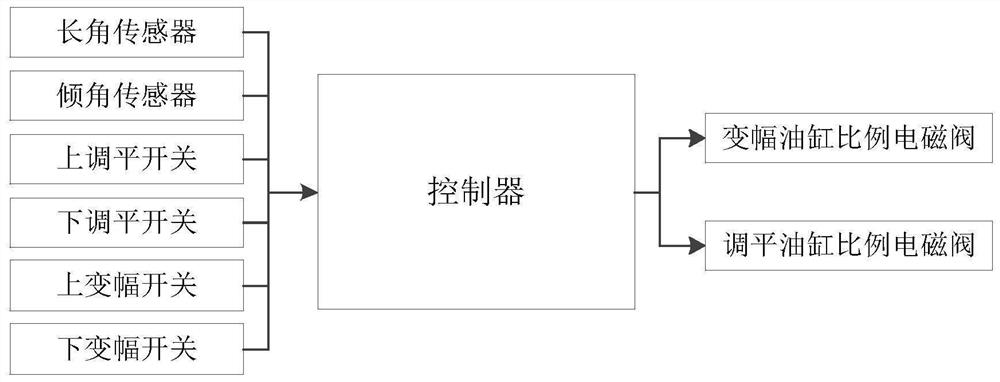

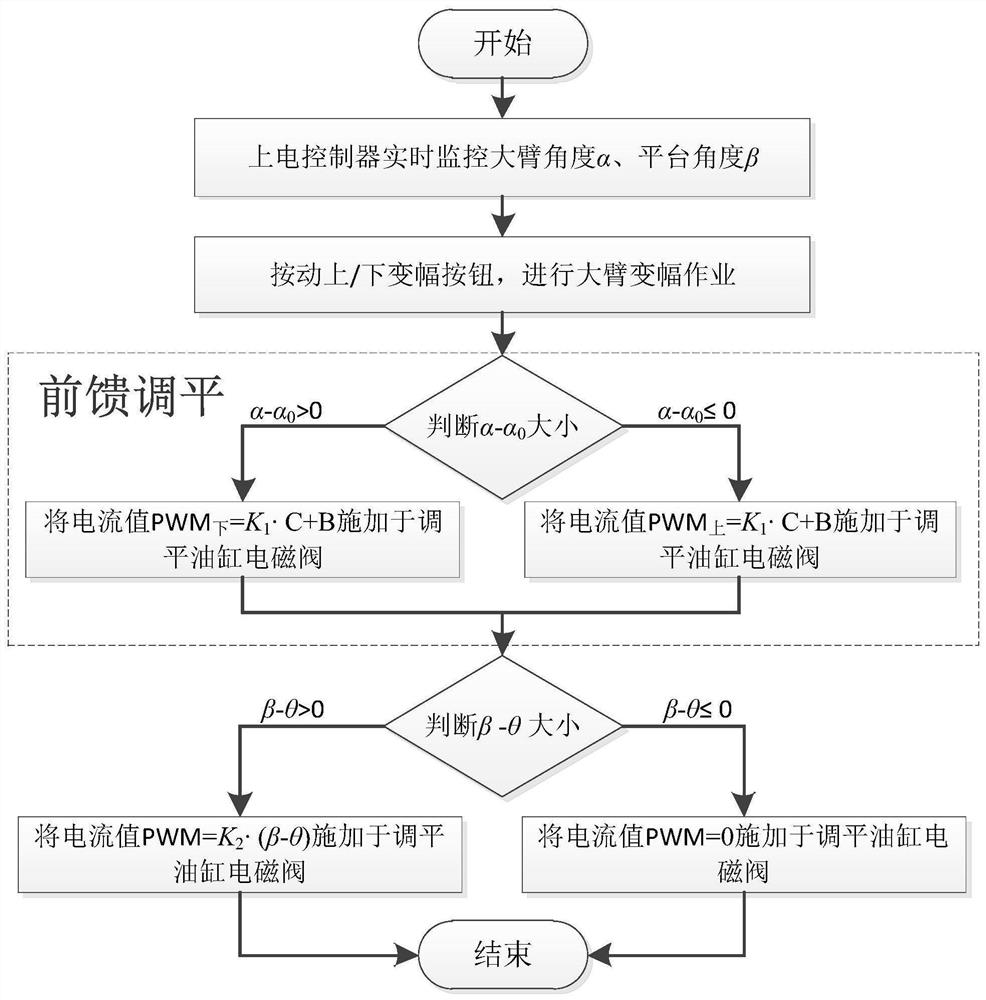

[0041] In order to realize the automatic leveling action of the straight-arm aerial work platform during the luffing process, the controller is used as the control core unit, and the relevant sensors, switches, actuators and other components are selected. The specific input and output components include long angle sensor, inclination sensor, up leveling switch, down leveling switch, up luffing switch, down luffing switch, luffing cylinder solenoid valve and leveling cylinder solenoid valve, etc. The long angle sensor is responsible for detecting the luffing angle and telescopic length of the boom, the inclination sensor is responsible for detecting the inclination angle of the platform, the up / down leveling switch is responsible for manually controlling the inclination angle of the platform, and the up / down luffing switch is responsible for controlling the luffing angle of the boom Action, luffing cylinder solenoid valve and leveling cylinder solenoid valve are the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com