Vertical sealing device

A sealing device, a vertical technology, applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of leakage into the air chamber under the grate, increasing the operation of the cooler, maintenance costs, and aggravating the wear of the grate plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

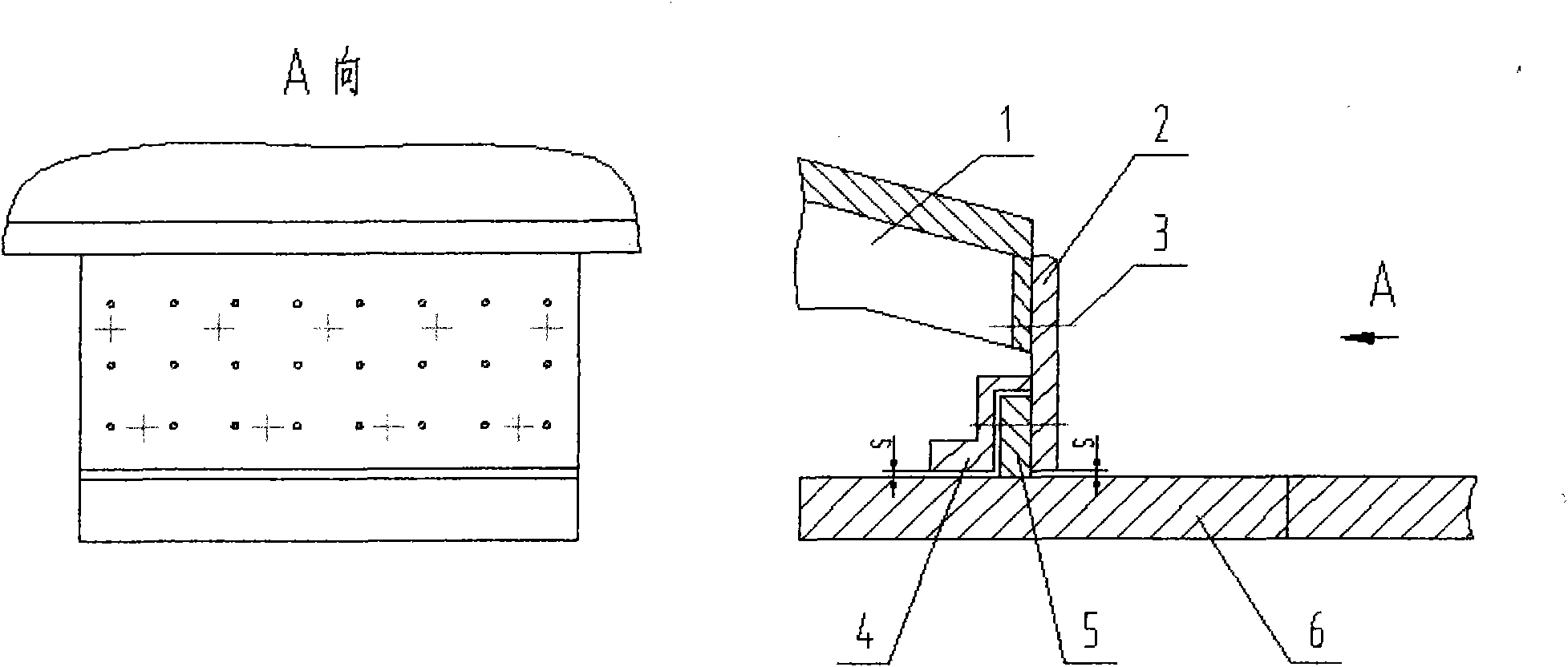

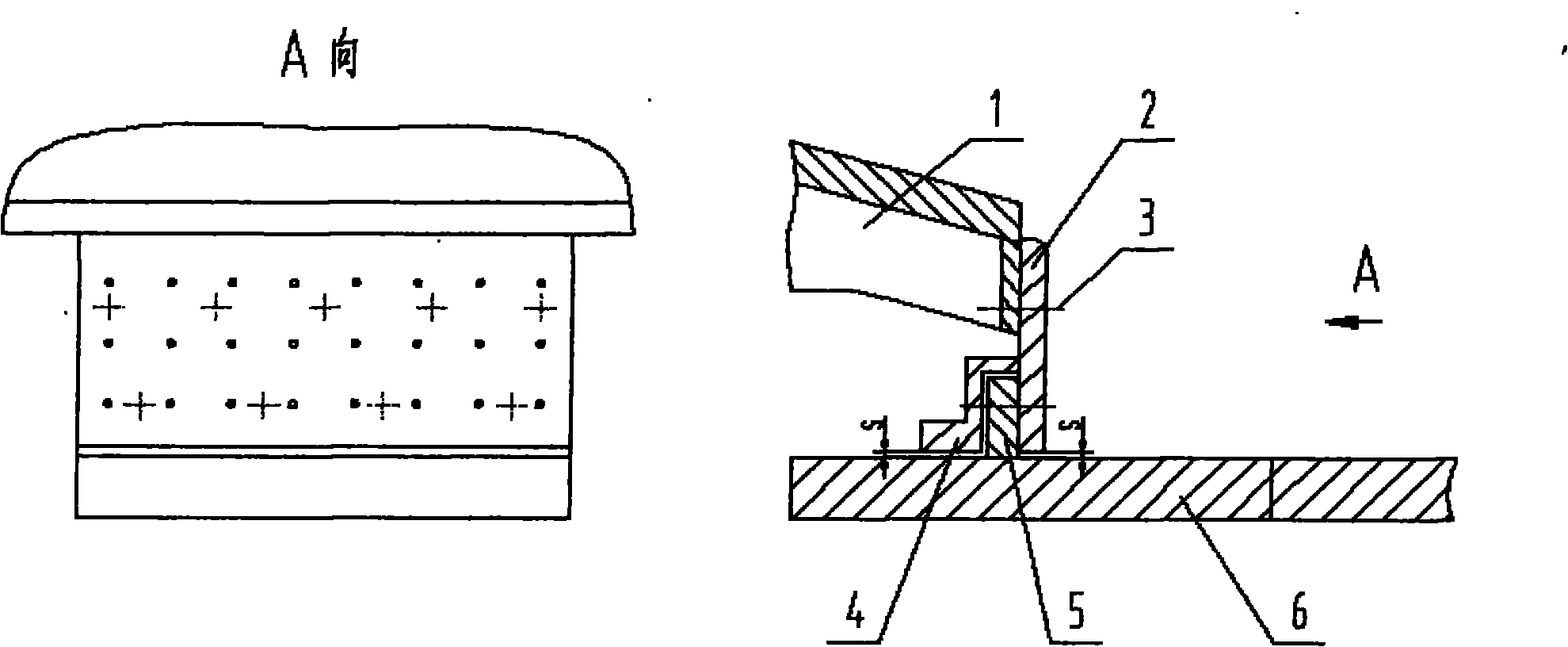

[0007] The following is attached figure 1 The present invention will be further described with specific embodiments.

[0008] The vertical sealing device shown in the figure is mainly composed of an entrance fixed section 1, a fixed baffle plate 2, a connecting bolt 3, a sealing strip block 4, a sealing strip 5, a movable bed 6, and the like. The vertical sealing device mainly achieves the sealing effect through the close contact between the sealing strip 5 and the movable bed 6 under its own gravity, the fixed baffle 2 is fixed on the entrance fixed section 1 through the connecting bolt 3, and the sealing strip stopper 4 and The fixed baffle 2 jointly fixes the sealing strip 5 to prevent it from moving longitudinally and losing its sealing effect.

[0009] During use, an appropriate number of fixed stoppers 2, sealing strip stoppers 4 and sealing strips 5 can be selected according to the width of the entrance fixed section 1 and the movable bed 6 for installation. First, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com