Barrel cam shift mechanism

A technology of barrel cam and shifting mechanism, which is applied in the direction of cams, mechanical equipment, controlled components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

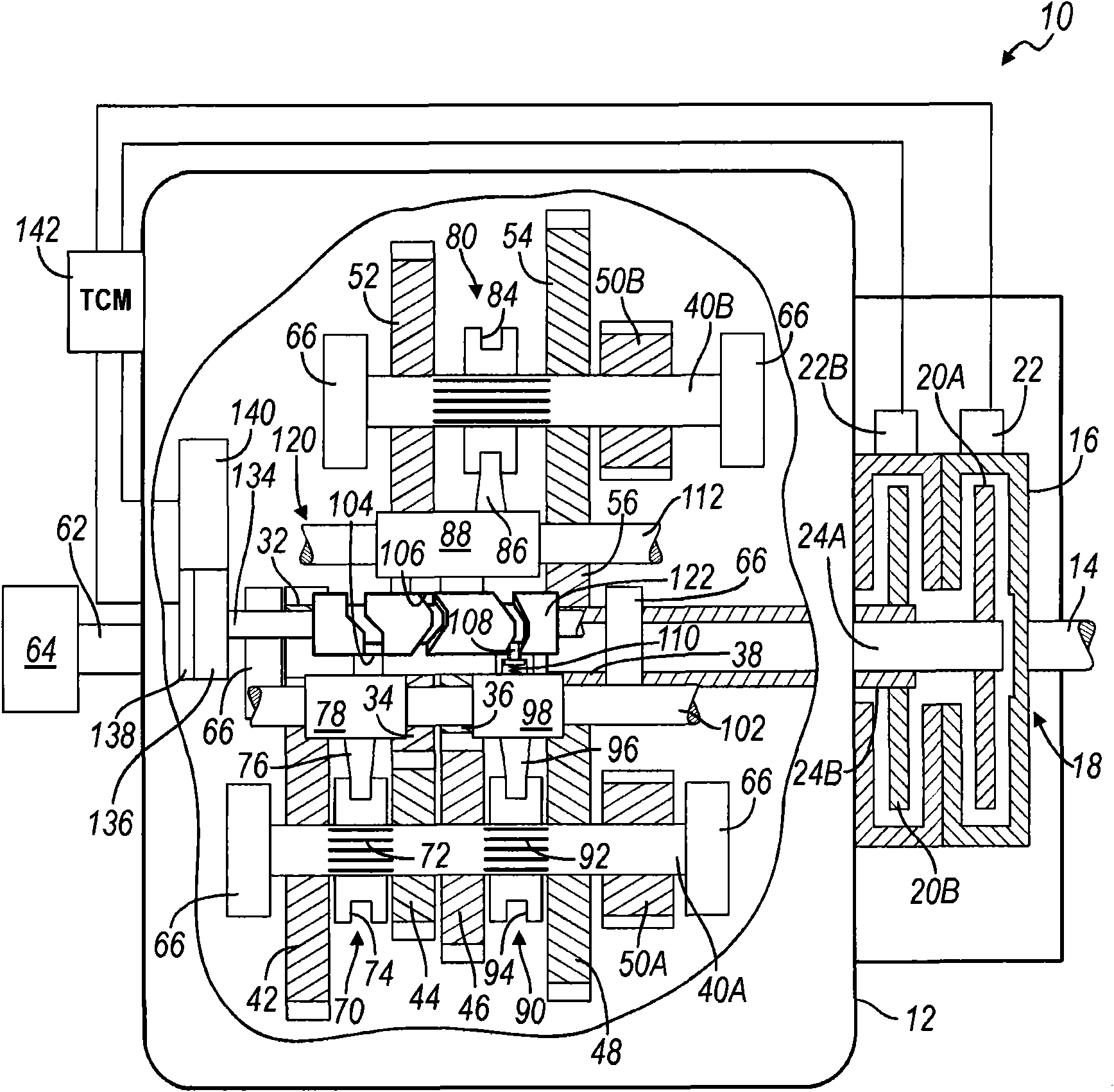

[0057] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or use. figure 1 , it should be understood that some parts have been rotated out of their actual positions and into the plane of the view for clarity.

[0058] refer to figure 1 , shows a dual clutch transmission containing a barrel cam shifting mechanism according to the invention, which is generally indicated by reference numeral 10 . The dual clutch transmission 10 includes a housing 12 having a plurality of bores, openings, flanges, etc. that receive, locate and retain components of the transmission 10 . The input shaft 14 is coupled to and driven by a prime mover (not shown), such as a gasoline engine, diesel engine, hybrid or electric power plant. The input shaft 14 is coupled to an input or housing 16 of a dual clutch assembly 18 . The dual clutch assembly 18 includes a pair of input clutches, a first input clutch 20A and a second input clutch 20B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com