Cooling trough

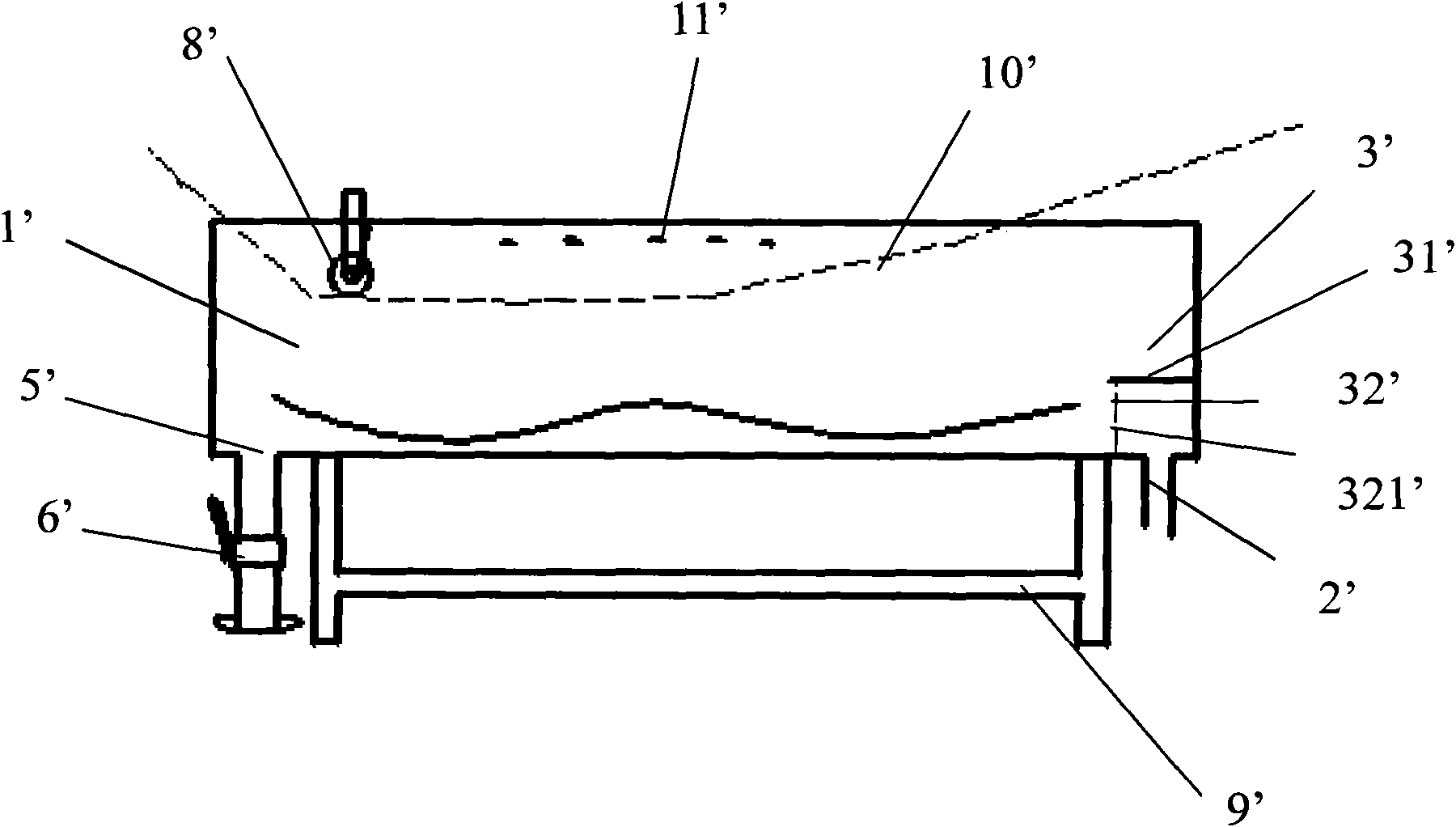

A technology for cooling the water tank and the water tank body, which is applied in the direction of grease/oily substance/floating matter removal device, liquid separation, direct contact heat exchanger, etc., and can solve the problem of inability to collect, stick, and affect the cooling effect of the material strip 10', etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

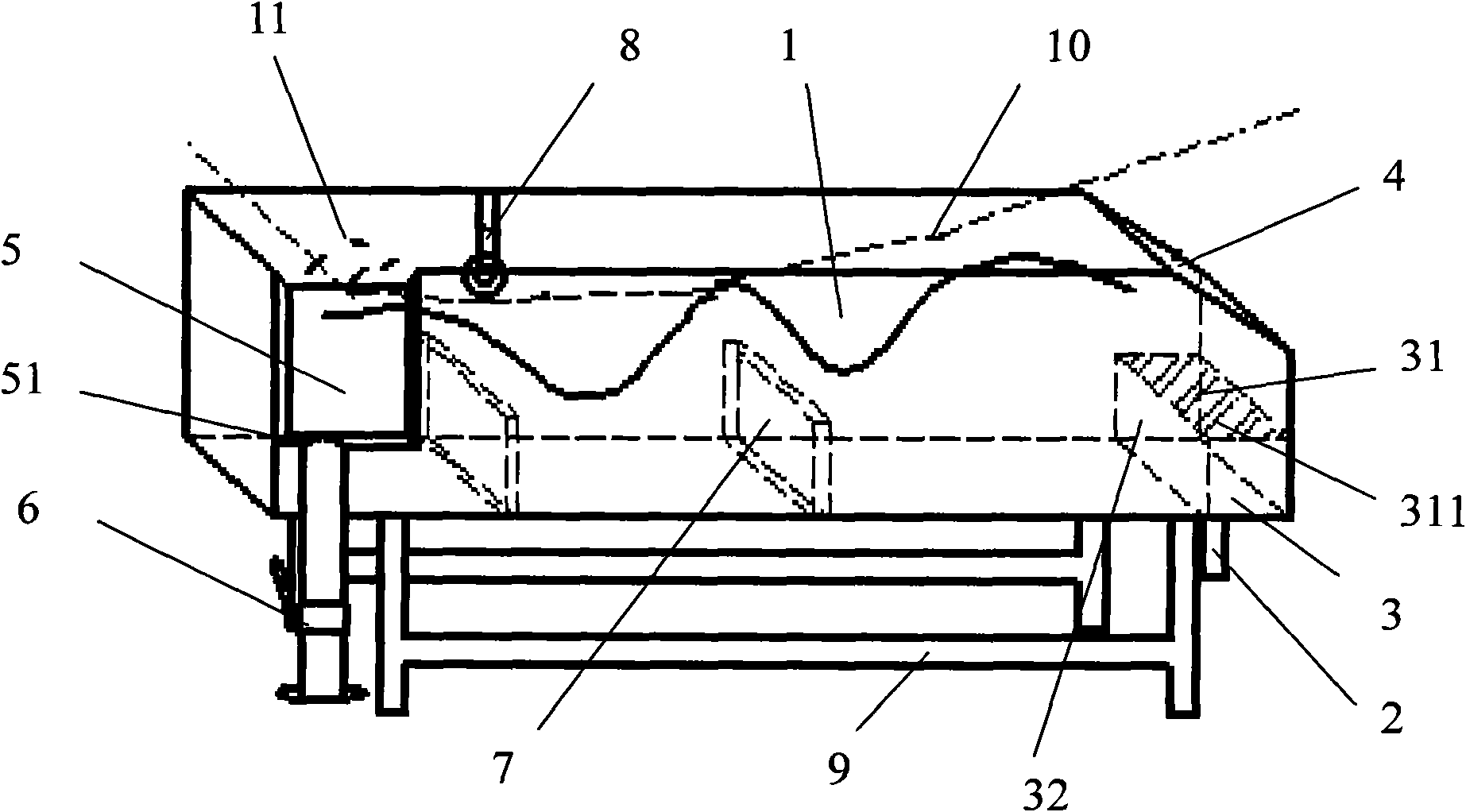

[0021] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0022] See figure 2 As shown, the cooling water tank of the present invention includes a water tank body 1, a bracket 9, a water inlet 2, a sewage collection outlet 5, a drain valve 6, a buffer plate 3, a batten wheel 8, and a water flow baffle.

[0023] The bracket 9 is arranged below the sink body 1 to support the sink body 1 . The batten wheel 8 is arranged on the top of the tank body 1 . The water inlet 2 is arranged at the bottom of one end of the sink body 1 .

[0024] The buffer plate 3 is arranged above the water inlet 2 at the bottom of the tank body 1; the buffer plate 3 includes a top plate 31 provided with a plurality of slot holes 311 and a closed side plate 32, the top plate 31 and the side plate 32 form a right angle; the side plate 32 is vertically arranged At the bottom of the sink body 1 ; the top plate 31 is arranged above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com