Dam maintenance ladder

A technology of dams and ladder rods, which is applied to ladders, electrical components, mechanical equipment, etc., can solve the problems of short service life of equipment, easy brittleness of equipment materials, and loss of internal temperature, so as to improve the quality of protection, protect equipment safety and The safety of personnel use and the effect of ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

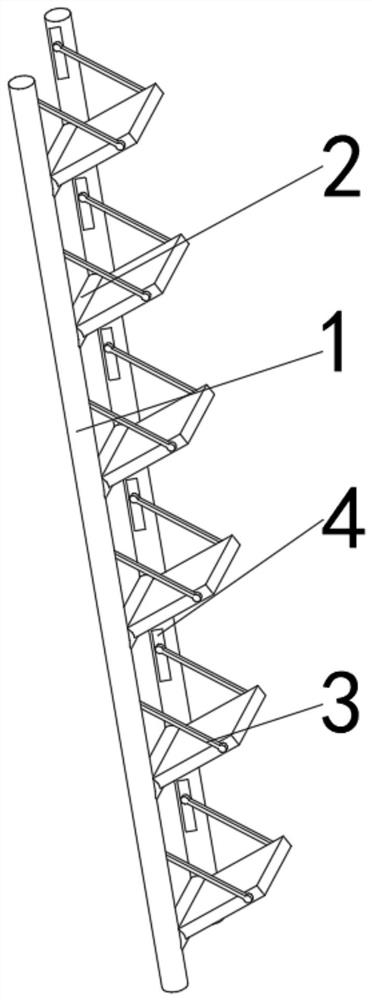

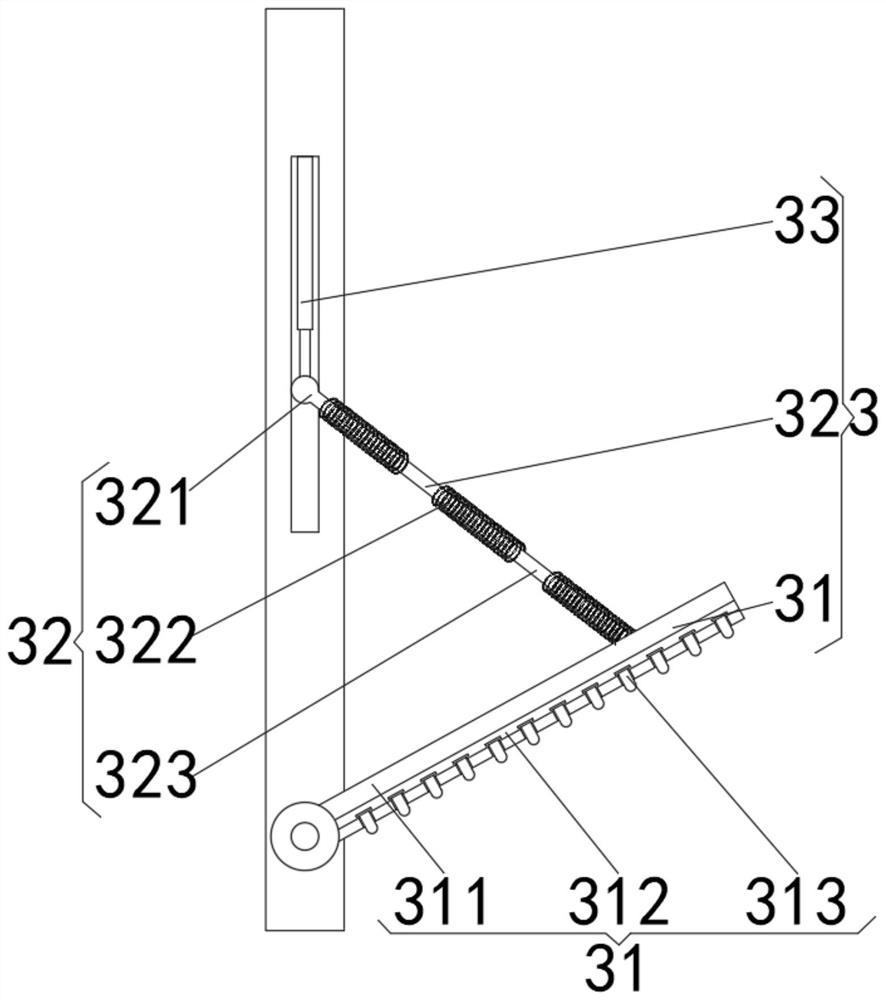

[0040] see Figure 1-2 , the present invention provides a technical solution: a dam maintenance ladder, including a ladder bar 1, a mounting shaft 2 is movably connected to the side of the ladder bar 1 close to each other, a pedal 3 is movably connected to the right side of the outer surface of the mounting shaft 2, and the ladder bar 1 There is a mounting groove 4 on one side close to each other and above the mounting shaft 2;

[0041] The pedal 3 includes a main board 31, the front and back of the main board 31 and the side away from the installation shaft 2 are movably connected with an adjustment rod 32, and the end of the adjustment rod 32 away from the main board 31 is movably connected with a telescopic rod 33, and the end of the telescopic rod 33 is far away from the adjustment rod 32 It is movably connected with the installation groove 4.

[0042] The main board 31 includes a plate body 311. The side of the plate body 311 away from the ladder bar 1 is provided with a...

Embodiment 2

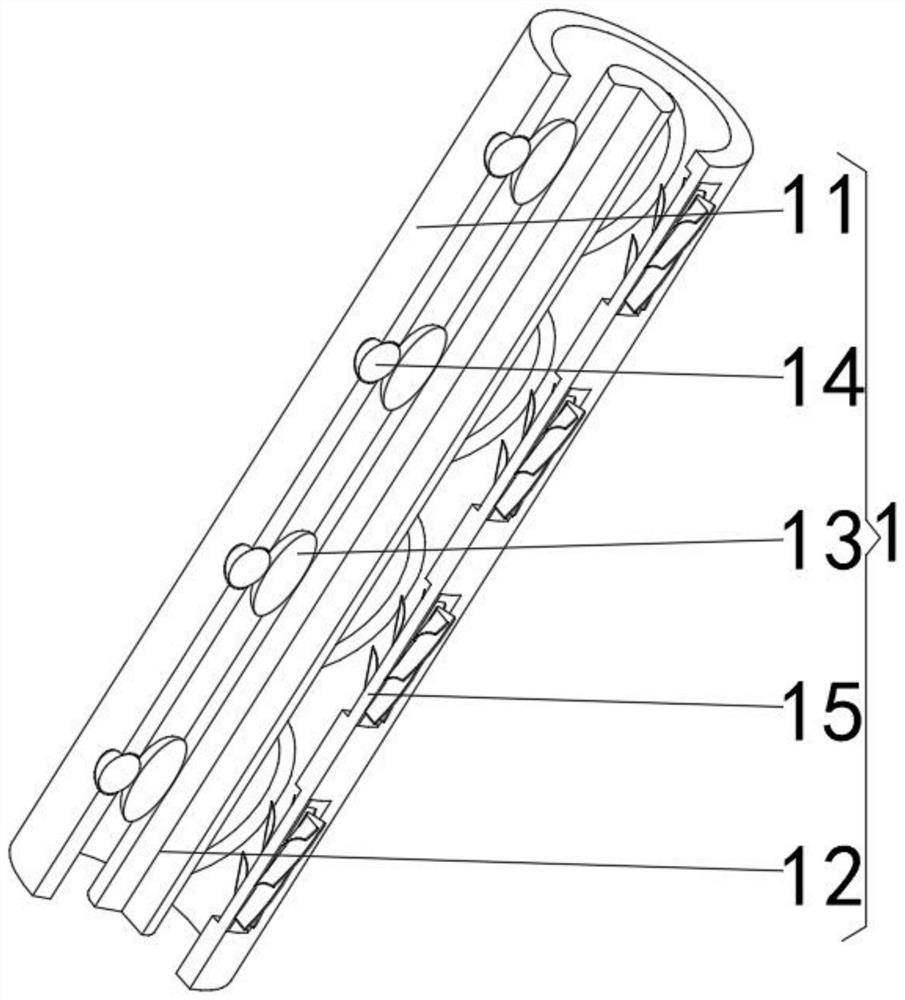

[0047] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a technical solution: the ladder rod 1 includes a rod barrel 11, and the inner surface of the inner cavity of the rod barrel 11 is fixedly connected with a rebound mechanism 12 on the side close to the installation shaft 2, and the rebound mechanism 12 The side away from the installation shaft 2 is movably connected with a buffer ellipse 13, the outer surface of the rod barrel 11 is fixedly connected with an anti-collision mechanism 14 at the side far from the installation shaft 2 and at the position of the buffer ellipse 13, and the outer surface of the rod barrel 11 is front A guide vane 15 is fixedly connected to the position of the rebound mechanism 12 .

[0048] The buffer ellipse 13 is flexibly connected to the anti-collision mechanism 14 on the side away from the rebound mechanism 12. The guide vane 15 penetrates the rod barrel 11 and extends to the inner cavity of the rod barrel 11. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com