Joint fastening member and fastening connecting member

A technology for fastening connectors and fasteners, applied in the direction of connecting components, threaded fasteners, locking fasteners, etc. Connecting parts are loosened and other problems to prevent loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (Embodiment 1, joint fastener)

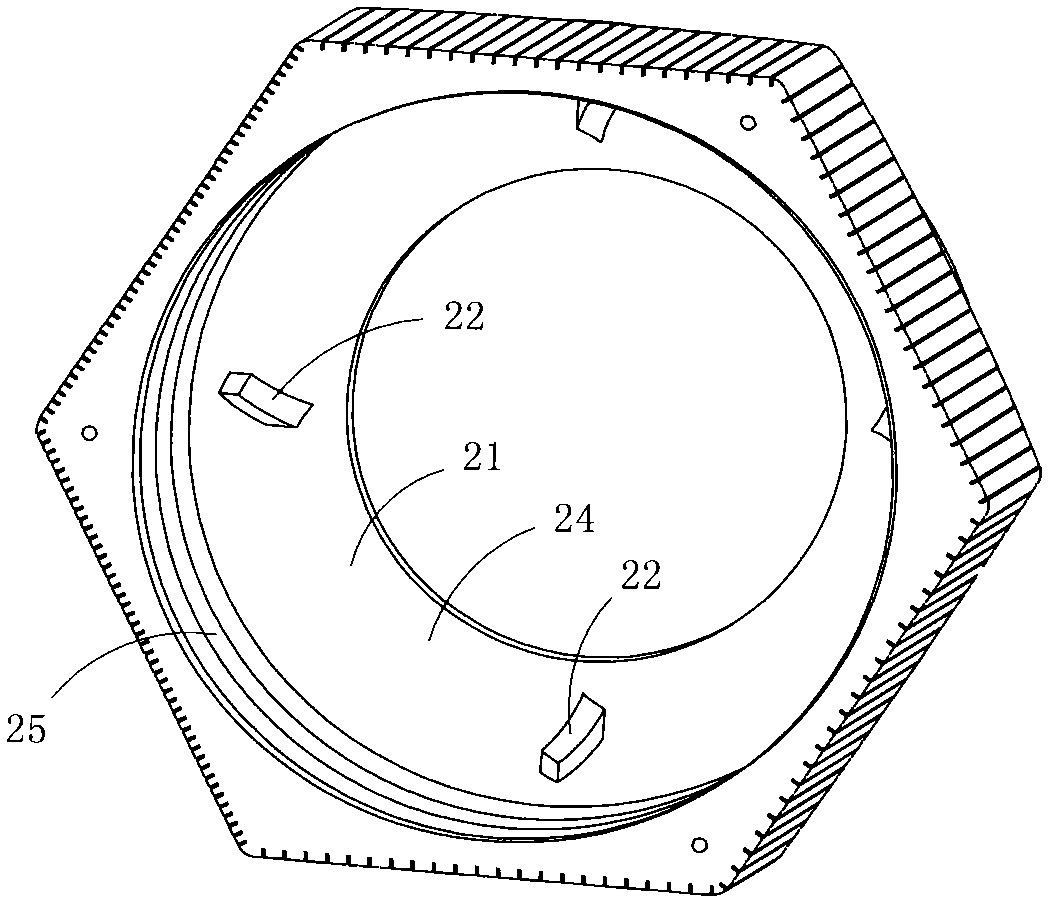

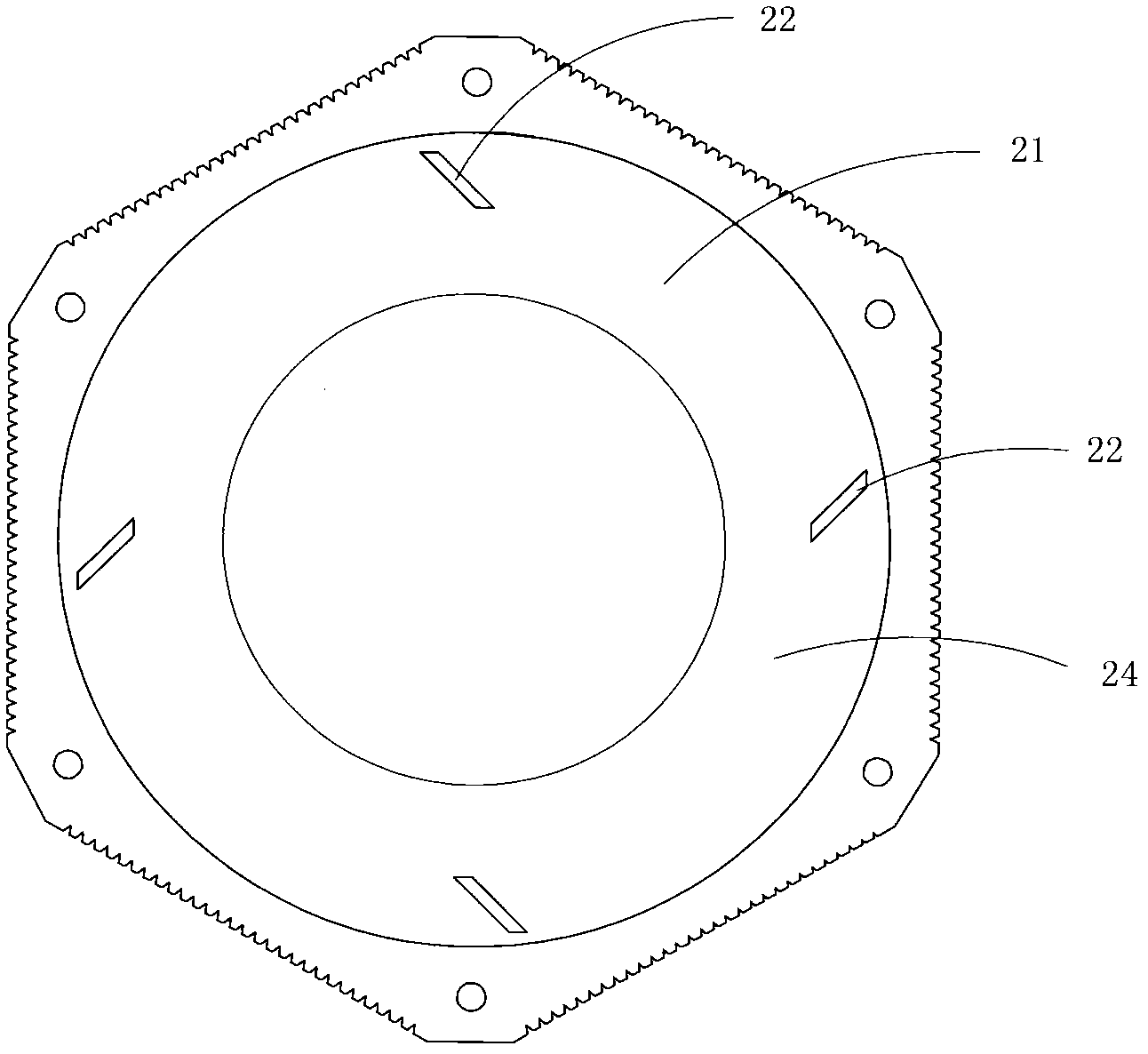

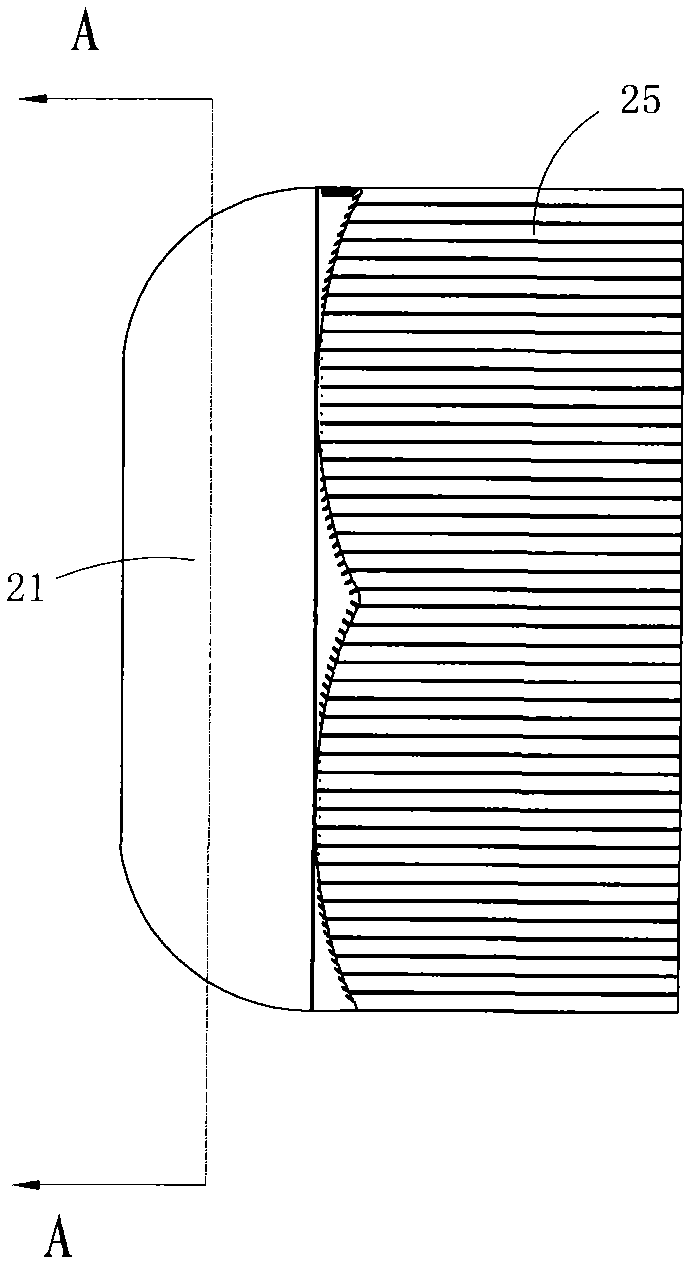

[0031] Figure 1 to Figure 4 An embodiment of the joint fastener of the present invention is shown, wherein, figure 1 It is a three-dimensional structural schematic diagram of the first structure of the joint fastener in the present invention; figure 2 yes figure 1 An elevational view of the joint fastener shown; image 3 yes figure 1 A side view of the joint fastener shown; Figure 4 yes image 3 Sectional view along line A-A.

[0032] This embodiment is a joint fastener, see Figure 1 to Figure 4 Its basic shape is tubular, including a fastening area 25 with an internal thread and a crimping area 21 with a crimping surface 24 inside. The crimping surface 24 is provided with several raised anti-skid teeth 22 . The anti-slip teeth 22 are evenly distributed on the crimping surface 24 and arranged equidistantly around the central axis of the joint fastener 1 . See figure 2 As shown, the extension direction of each anti-slip too...

Embodiment 2

[0034] (Embodiment 2, Joint Fastener)

[0035] Figure 5 It is a longitudinal sectional view of the second structure of the joint fastener in the present invention, showing the second specific embodiment of the joint fastener in the present invention.

[0036] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 5 , the shape of the longitudinal section of each of the anti-skid teeth 22 is a right-angled trapezoid.

Embodiment 3

[0037] (Embodiment 3, joint fastener)

[0038] Figure 6 It is a longitudinal sectional view of the third structure of the joint fastener in the present invention, showing the third embodiment of the joint fastener in the present invention.

[0039] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 , the shape of the longitudinal section of each anti-skid tooth 22 is an isosceles trapezoid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com