Sampling device of filter stick forming machine

A molding unit and sampling device technology, which is applied to sampling devices, e-liquid filter elements, tobacco, etc., can solve the problems of air leakage in the launch pipeline, failure of filter rods to be sent normally, and influence on data collection of related indicators, so as to improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

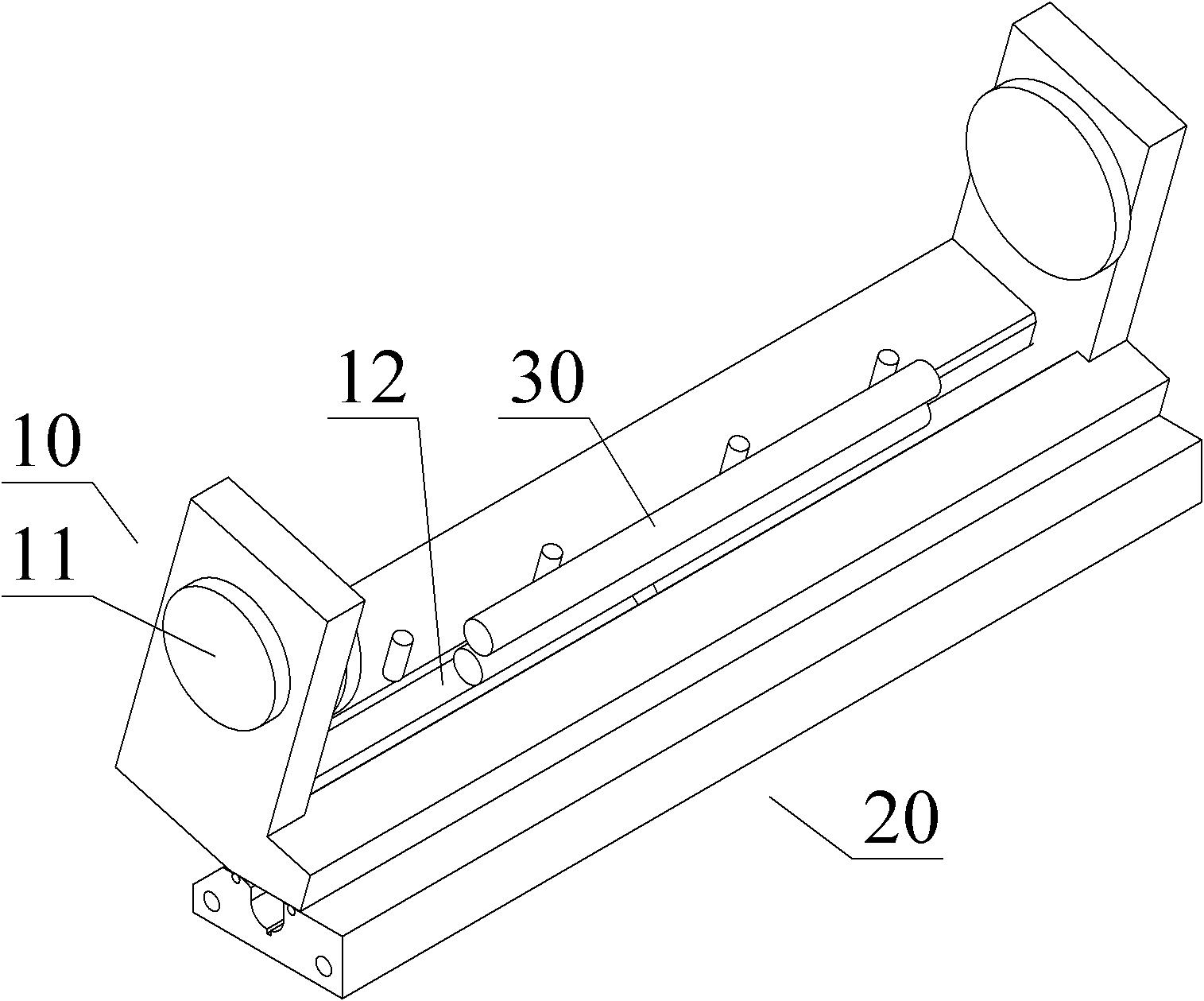

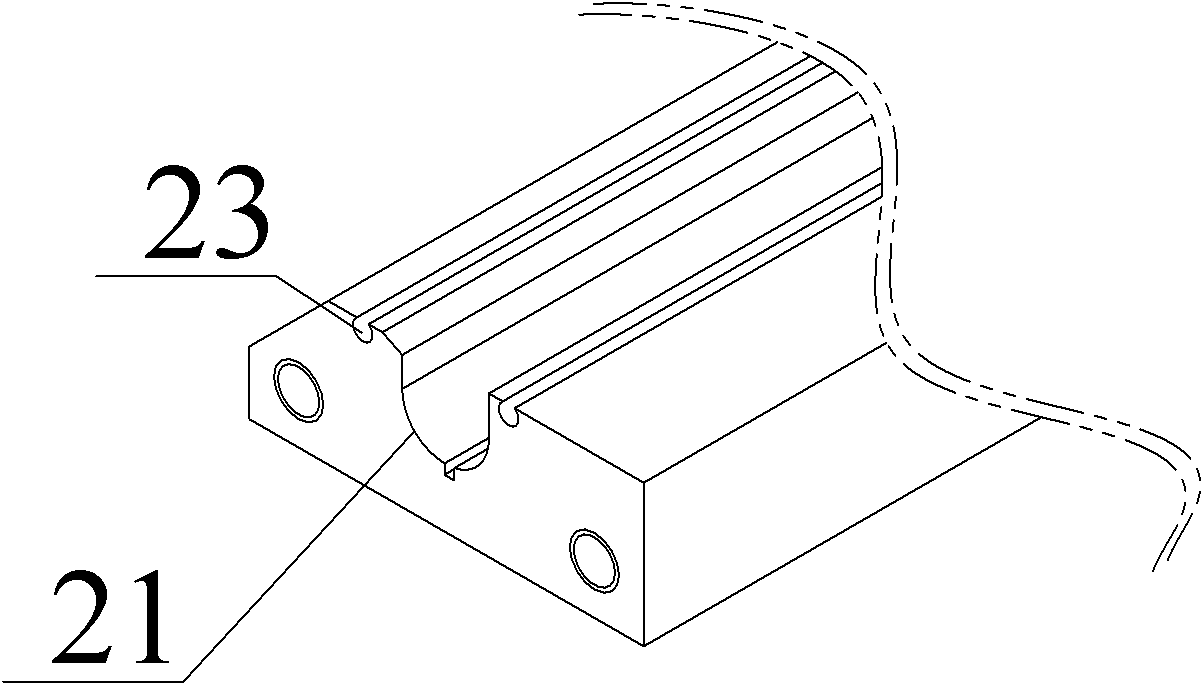

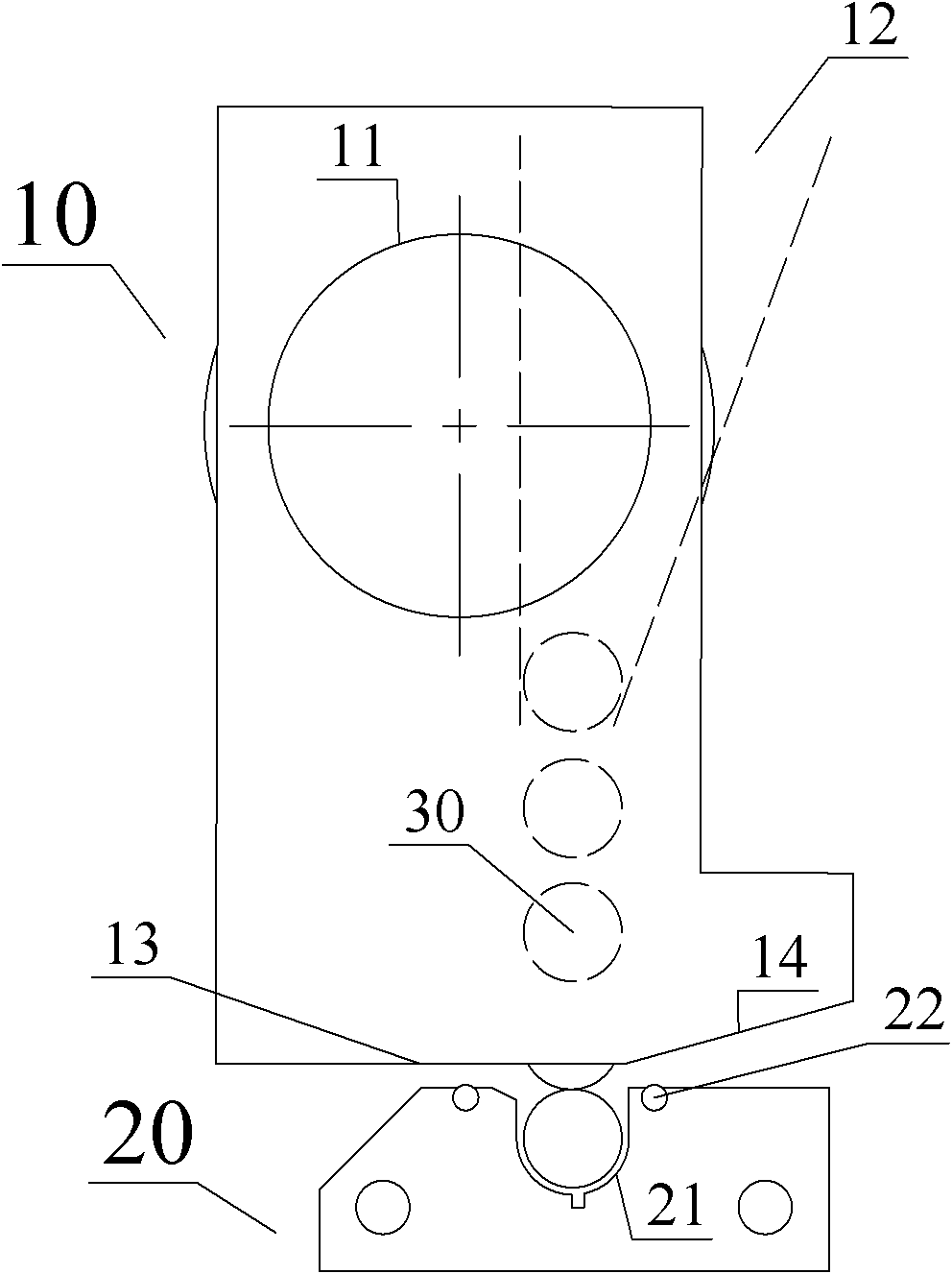

[0018] figure 1 It is a structural schematic diagram of the sampling device of the filter rod forming unit involved in the present invention. The sampling device comprises a movable socket 10 rotating around a fixed shaft 11 and a fixed tube sheet 20 arranged under the movable socket 10, and the bottom of the movable socket 10 is connected with first and second rigid surfaces 13, 14 The surface of the fixed tube sheet 20 is provided with a receiving groove 21 connected to the outside world, and the cavity in the receiving groove 21 can accommodate the filter rod 30 . A conveying channel 12 is arranged inside the movable sleeve 10, and the conveying channel 12 is a hopper, and the outlet of the hopper is on the first rigid surface 13. The stationary tube sheet 20 periodically receives filter rods 30 . When the first rigid surface 13 moves above the fixed tube sheet 20, see image 3 , 4 , the receiving groove 21 is facing the hopper, and the filter rod 30 can fall into the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com