Warehouse management system and method

A warehouse management system and warehouse management technology, which is applied in the field of incoming material quality control and inspection program automation, can solve the problems of time-consuming, labor waste, error-prone inspection data, etc., and achieve the effect of speeding up the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides a warehouse management system and method. Several specific embodiments of the present invention are disclosed as follows.

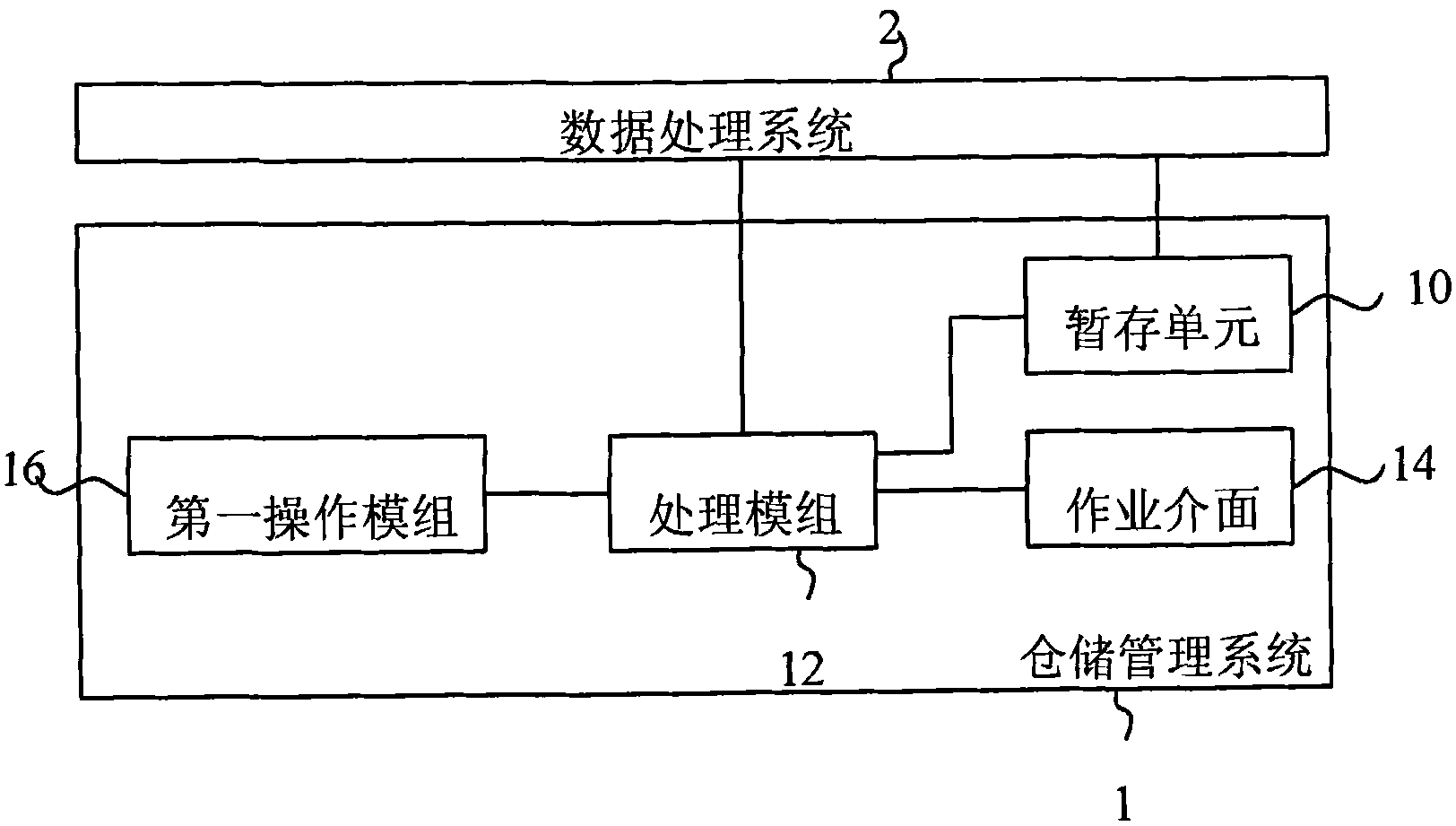

[0033] See figure 1 , figure 1 A block diagram of a warehouse management system according to a specific embodiment of the present invention is shown. Such as figure 1 As shown, the warehouse management system 1 includes a temporary storage unit 10 , a processing module 12 , an operation interface 14 and a first operation module 16 . Wherein, the processing module 12 is respectively connected to the temporary storage unit 10 , the operation interface 14 and the first operation module 16 . In addition, the first operation module 16 can be connected to the processing module 12 through other devices. ) device, the first operation module 16 can be further connected with the processing module 12 through wireless communication technology to realize long-distance data exchange.

[0034] The temporary storage unit 10 can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com