Pressure filter for cross-flow and parallel-flow cross filtering

A technology of filter press and chamber filter press, which is applied in the field of filter press, can solve the problems of prolonged filtration time, uneven distribution of particle layers in the filter cake layer, and difficult filtration, so as to improve filtration efficiency and fine particle distribution Layer uniformity, improve the effect of filtering conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

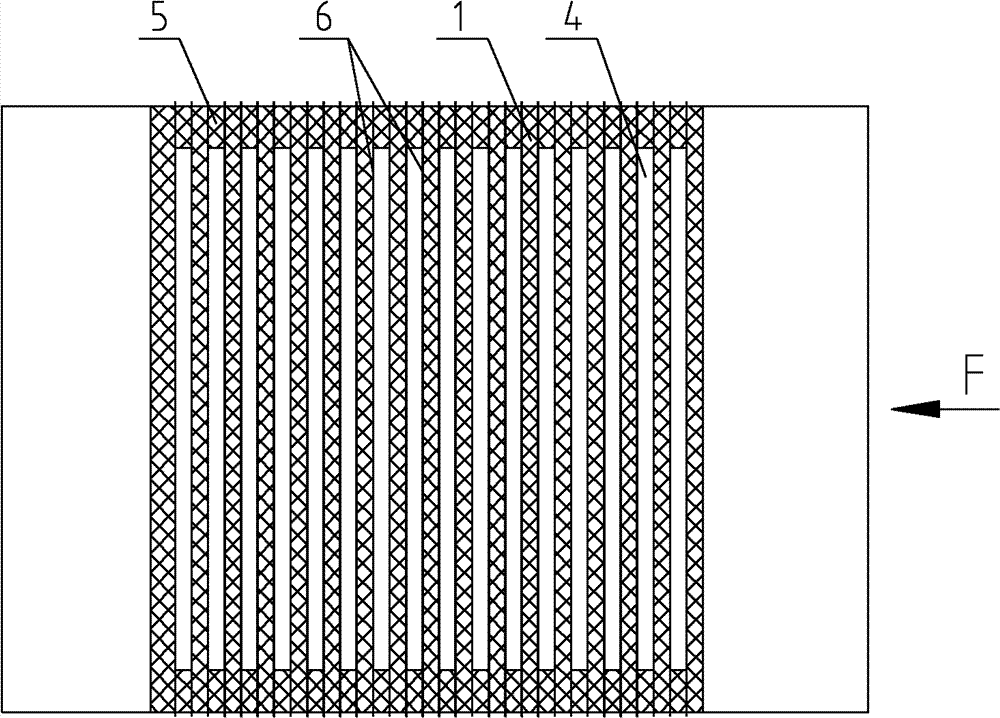

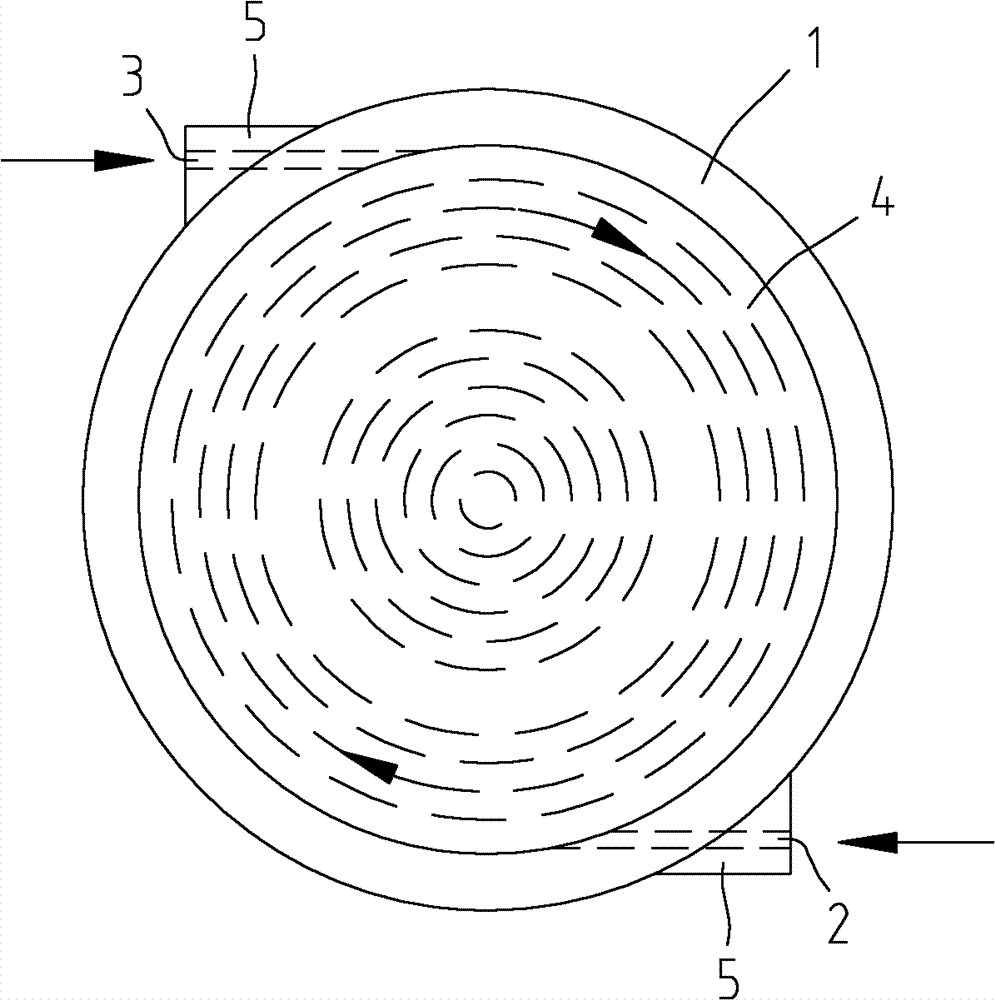

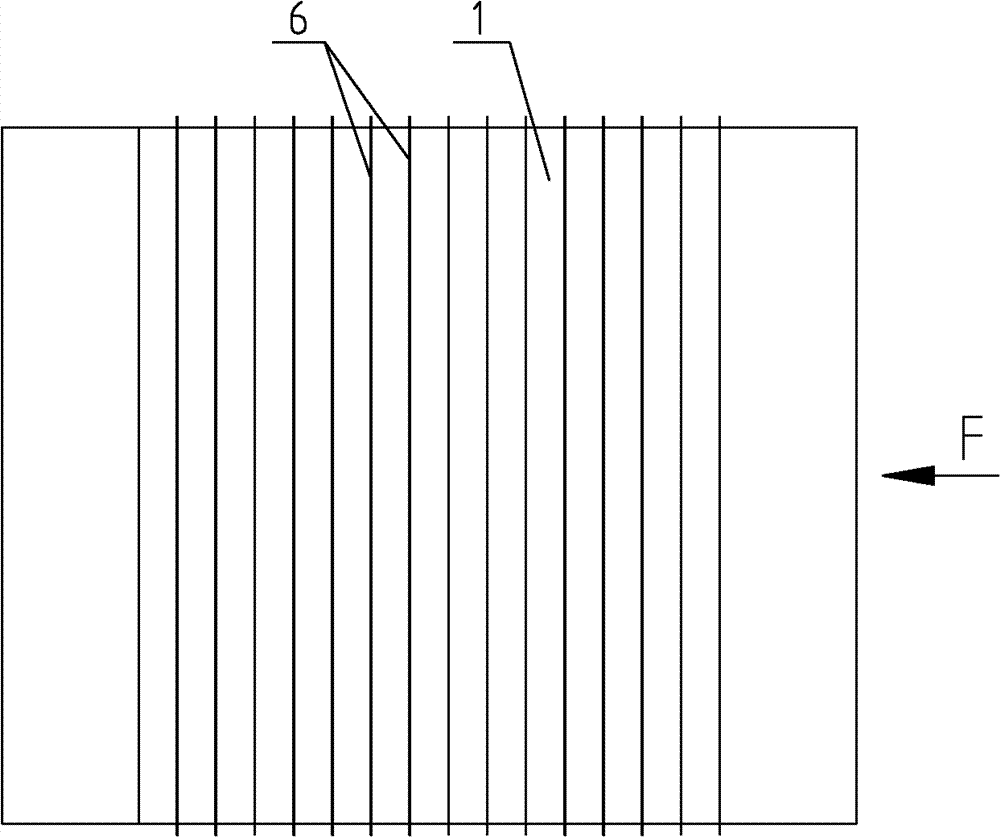

[0028] Such as Figure 1 to Figure 5 As shown, it is a filter press of the present invention with cross-flow and cross-flow filtration. Filter elements are arranged in the filter press, and filter chambers 4 are formed between adjacent two filter elements. The feeding port 2 and the main feeding port 2 are located on the same plane as the filter element, and the direction of the main feeding port 2 is along the inner wall of the filter chamber 4 . The filter element is also provided with an auxiliary feed port 3, the auxiliary feed port 3 and the main feed port 2 are respectively arranged at the two corners of the diagonal line of the filter element, and the particles trapped by the filter medium 6 are pushed by the feed. Rotate as a vortex and flow to the center of the vortex. The opening of the auxiliary feeding port 3 and the opening of the main feeding port 2 are parallel to each other. The main feeding port 2 is arranged at the bottom of the filter element, and the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com